Appointment of the brake booster

The vast majority of modern cars use a hydraulic brake system. It implies that the force required to compress the brake pads is created by the driver himself when the brake pedal is pressed. Through the main brake cylinder, the force is transmitted to the brake cylinders placed on the wheels with the help of an incompressible fluid. From the cylinders, the force is transferred to the brake pads, which carry out the braking.

A disadvantage of a hydraulic braking system is that the driver must apply a sufficiently large amount of force to compress the brake pads. In addition, the required force depends on the weight of the car and increases with increasing speed at which braking is performed. During a long trip or city driving, the brake pedal can be pressed dozens or even hundreds of times, which leads to rapid driver fatigue. And this can already affect the safety of traffic.

The purpose of the vacuum brake booster lies in the very name of the part. It is designed to increase the force applied by the driver, while transmitting the impact to the brake cylinder and further to the brake pads. The vacuum booster increases the pressing force several times, which makes braking more efficient and reduces the physical burden on the driver.

The device and features of the vacuum brake booster (video)

If you ask an elderly person who has ever driven a Soviet car what it was like to slow down at high speed, he will unequivocally answer: it was hard. I had to press the brake pedal to the floor, often even get up, transferring all the weight on one foot. The invention and rapid introduction of brake boosters made it possible to solve this problem. What is the problem, you ask? The fact that braking, which is highly dependent on the physical condition of the driver, may not always be effective. And a car with such an imperfect brake in terms of ride comfort will certainly lose to its current brother. Let's look at the device of the most common brake booster and consider what kind of malfunctions it has.

Vacuum brake booster device

The vacuum amplifier has a fairly simple design. It is combined with the master brake cylinder into a single system in which the booster plays the role of a "transmitter" of force from the brake pedal.

The amplifier itself is a cylindrical body, the internal volume of which is divided by a diaphragm into two sealed chambers: vacuum and atmospheric. The vacuum chamber is located on the side of the brake cylinder and is connected to its piston by means of a rod. Also in the vacuum chamber is a check valve that prevents pressure build-up when the engine is turned off.

The atmospheric chamber is located on the side of the brake pedal. In the atmospheric chamber there is a follow-up valve connected by means of a pusher to the brake pedal. It is the follower valve that plays the main role in the amplifier - its movement allows the atmospheric chamber to communicate either with the vacuum chamber or with the atmosphere.

What is a brake booster valve

Many vehicles use a vacuum brake booster to increase braking force. It creates a constant flow of brake fluid to the brake master cylinder, increasing brake pressure and helping the vehicle stop more quickly. This element is very common on cars, SUVs and pickup trucks. Over time, the brake booster can become damaged or wear out. The same thing can happen with the brake booster control valve.

The brake booster valve is an element of the car's brake system and is designed to remove air from the brake booster and prevent it from entering the cylinder. In this way, the pipelines of the brake system are protected from air, which can seriously reduce the efficiency of the brake system. The valve connects the vacuum booster housing and the vacuum hose - a safe technical solution that ensures the brakes work even when the engine is turned off.

As a rule, the control valve of the vacuum brake booster is not checked during periodic maintenance. However, there are situations in which signs of wear or complete failure of the valve may be observed. The following are some of the signs by which you can conclude that there may be a problem with the brake booster control valve. Remember that these are just general signs. To determine the exact cause of the malfunction and carry out repairs, you must contact a qualified specialist.

Operating principle

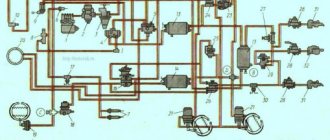

For the full operation of the vacuum brake booster, it needs a vacuum. It is created by connecting an amplifier to the intake manifold or by operating a special pump. In diesel cars, the pump always provides the booster, in gasoline cars, both options are found.

The vacuum booster has a pneumatic principle of operation and uses the pressure difference in chambers separated by a diaphragm. At the moment when the brake pedal is depressed, the pressure in the atmospheric and vacuum chambers of the amplifier is equally low, since both chambers have a message through the vacuum channel in the diaphragm.

After the driver presses the brake pedal, the force created by the driver is transmitted to the follower valve. The valve gradually closes the vacuum channel and opens the atmospheric one in the atmospheric chamber. As a result, the pressure in the atmospheric chamber exceeds the pressure in the vacuum chamber, due to which the diaphragm begins to move towards the brake cylinder. Due to the pressure difference, the diaphragm creates a force on the cylinder rod that is several times greater than the force when the driver presses the brake pedal. The follower valve is designed so that the more force the driver gives to pressing the brake pedal, the greater the effect of the valve on the piston of the brake cylinder.

If, after pressing the brake pedal, the driver stops the impact (holds the foot in a certain position), then the movement of the diaphragm and the brake boost itself stop. In response to the force of the pedal, the vacuum brake booster can increase the effect of braking force, reduce it, or leave it at its current level. Thus, the operation of the vacuum brake booster is completely under the control of the driver.

After the brake pedal is depressed by the driver, the reverse process occurs. The follower valve closes the atmospheric channel again and opens the vacuum one. The pressure difference in the atmospheric and vacuum chambers of the brake booster disappears, the diaphragm and the piston of the brake cylinder return to their original places under the influence of a return spring located in the booster housing.

The operation of the amplifier does not depend on whether the engine is turned off or turned on. Its constant operation is ensured by a check valve that prevents pressure build-up in the chamber.

Features of the operation of the vacuum brake booster

Since the vacuum brake booster uses the difference between atmospheric pressure and the pressure in the vacuum chamber, the ambient air pressure is of great importance. A pressure of about 0.067 MPa is created in the vacuum chamber, which is about 1.4 times less than the usual atmospheric pressure. Under conditions of standard altitude above sea level, approximately the same ratio is maintained. As the height increases, the efficiency of the vacuum brake booster gradually decreases.

Above 3.5 km above sea level, the ambient air pressure and the pressure in the vacuum chamber will equalize, and the brake booster will simply not work. Therefore, on equipment operating in high altitude conditions, brake boosters of a different design are used, which do not depend on external atmospheric pressure.

Symptoms of a malfunctioning vacuum brake booster

Due to the prolonged operation of the vacuum brake booster without replacement, defects may appear in it. Most often, the problem manifests itself in mechanical damage to the hose connection connecting the amplifier and the engine intake manifold. Mechanical damage or the formation of cracks in the rubber will lead to the fact that a vacuum will not be created in the working chamber of the mechanism, and this is necessary for its proper operation.

Internal parts can also fail in the vacuum brake booster, for example, the valve will lose elasticity or the working surface of the diaphragm will be damaged.

You can determine the malfunction of the vacuum brake booster by the following signs:

- The car began to slow down worse with the same pedal pressure;

- While pressing the brake pedal, hissing sounds are heard, at this moment the engine speed may increase;

- The car starts to "troit";

- Fuel consumption increases when the machine is running in the same mode.

In some situations, there may be other problems in the operation of the car due to problems with the vacuum brake booster. For example, spark plugs may stop working.

How to find out about a malfunction of the brake booster

A malfunctioning brake booster directly affects the performance of the vehicle. Signs of an amplifier failure are:

- general deterioration in vehicle braking (increased stopping distance);

- the need to exert great effort in order for the car to slow down;

- in some cases, tripping of the car engine at idle is observed due to excess air entering the intake manifold with insufficient tightness of the vacuum booster system.

By itself, the failure of the brake booster does not mean that the brake system of the car will completely fail. In this case, the brake pressure is directly transmitted through the booster to the brake cylinder, but, of course, already without amplification.

How a vacuum brake booster works

The principle of operation of the mechanism is the same for different models. It works like this:

- During the operation of the power plant, at the time of suction of the air-fuel mixture through the valve in the intake manifold, a vacuum is created. The booster is connected to the intake manifold through a fitting. So a vacuum is formed in the working chamber.

- The design of the vacuum amplifier provides for the presence of two cavities separated by an elastic membrane. One of them is connected to the exhaust manifold, and the second to a valve having a channel for communicating with the atmosphere.

- When the internal combustion engine is running, the pressure in both cavities is the same. The displacement of the membrane is prevented by a spring installed in the working chamber. When exposed to the brake pedal, a valve opens, communicating the second cavity with the atmosphere. The response speed and intensity of impact depends on the degree of pressing the system control lever.

- Under the action of rarefaction, the membrane is displaced. The elastic diaphragm is connected to the working rod. This is how the plunger of the cylinder is affected.

- The fluid pressure in the pipelines rises. The actuators brake the wheels.

- After the driver releases the pedal, the pressure in both cavities becomes the same. The spring returns the elastic diaphragm to its original position. The impact on the actuators stops.

Adjusting the vacuum brake booster for different models is different. To carry out the work, you will need specialized equipment.

How to check the operation of the brake booster

You can check the regular operation of the amplifier using the following methods.

- With the engine off, press the brake pedal several times. The first press should be easy, subsequent ones will require more effort. The noise of the air passing into the atmospheric chamber should also be emitted.

- If the operation of the vacuum brake booster is provided by the intake manifold, then the following method will help determine the leakage of the system. With the engine off, pull out the intake manifold swirl flap hose. A normally working hermetic system with the hose pulled out should then begin to suck in air, which is also determined by noise.

- Also, with the engine turned off, you can press the gas pedal several times, then leave the pedal depressed and turn on the engine ignition. The pedal, for which it was just necessary to apply considerable effort, should easily and smoothly go “to the floor”.

- Another method helps to determine the presence of air leaks in the vacuum booster system. With the engine running, it is necessary to depress the brake pedal to the stop, and then turn off the engine. Then you need to hold the pedal depressed for 30-40 seconds. If at this moment the position of the pedal arbitrarily changes, then there are leaks in the system. If, after the specified time, the pedal is released and it begins to take the opposite position, then there is also a malfunction in the system - this behavior of the pedal signals an increase in pressure, which should not happen in such a situation.

Also, a violation of the tightness of the system can be determined visually by examining the air exhaust hose and its connection to the amplifier for leaks.

How to check the vacuum brake booster

The owner of the vehicle can independently determine the operability of the node. If the mechanism fails, you will need to press the brake pedal hard.

To check, place the vehicle on a flat surface. Stop the engine and pump the pedal several times. This is necessary to remove the vacuum from the working chamber. Press the pedal and hold it in that position. After starting the power plant.

If the control lever remains motionless, this indicates a malfunction. Normally, when starting the engine, the pedal should go down a little. This is due to the appearance of rarefaction in the cavity and the movement of the elastic membrane.

Repair and adjustment of the vacuum booster

The simplicity of the device of the vacuum brake booster also affects the solution of problems with its malfunction. Breakdowns inside the amplifier housing usually result in a complete replacement of the assembly. If leaks occur due to leaks in the air exhaust hose, you can replace it with a new one.

There are also small irregularities in the operation of the amplifier, which can be corrected by adjustment. For example, a misalignment of the diaphragm inside the body can be corrected by adjusting the stem position. It determines the amount of effort required by the driver on the brake pedal. The correct position of the rod should lead to the formation of a gap above the plane of the amplifier in the amount of 7.1 mm. If the gap is smaller, then the braking force will be transmitted to the main brake cylinder even without pressing the brake pedal. If the gap is larger, then the brake pedal will have too much travel. The rod position is adjusted using an adjusting bolt located on the side of the booster vacuum chamber.

In general, malfunctions of the vacuum brake booster are quite rare. The simplicity of the design ensures sufficient reliability of this element of the vehicle's braking system. However, if there are symptoms of a malfunction of the amplifier, which are confirmed by diagnostics, it is better to replace it with a new one. This not only reduces the burden on the driver, but also improves driving safety.

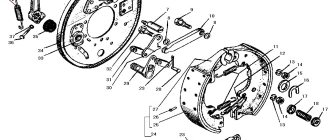

Vacuum booster device

The mechanism increases the fluid pressure in the system. There are two types of nodes:

- Combined with the master cylinder. It is located on one axis with the cylinder. The device increases the degree of impact on the plunger of the main cylinder.

- Located separately. It is used on some domestic trucks and specialized vehicles. Included in the hydraulic system in series. It has its own working cylinder.

On modern passenger cars, the first type of node is used. It is connected to the pedal block, has brackets for attaching the brake cylinder.

The body of the node is made of two parts. When connecting the body parts, a sealed seam is formed. An elastic membrane is sandwiched between the body parts. It is used to influence the vacuum on the working rod.

Main working elements:

- Spring. Serves to return the elastic membrane to its normal position.

- Valve. Tracks the impact on the brake control and opens a channel that communicates the working cavity with the atmosphere.

- Rod and pusher. Apply pressure to the fluid in the system.

- Union. Used to connect the working chamber to the intake manifold of the power plant.

The device of the vacuum brake booster for different models is the same. The list of parts for cars from different manufacturers is different. For a detailed examination of the device of a particular model, it is necessary to study the instruction manual.