In ads for the sale of a car, you can find many offers of not new, but quite decent cars in good condition. As they say, "ride and ride." But bad luck - a carburetor is installed on the selected machine. A rather old device in its type, which scares off modern motorists, especially young people, with its complexity, the possible lack of repair parts and possible breakdowns. Whether to buy a car with a carburetor, or find a more modern design with an injection fuel system - you can make a decision only after you understand the nuances of the operation and design of this device.

What is a carburetor and what is it for?

In order for an internal combustion engine to work optimally, it is necessary to mix fuel and air in a certain proportion and feed this mixture into the combustion chamber. The parameters of the mixture can change depending on the mode of operation of the internal combustion engine, fuel consumption - too, which means that a device is needed that will automatically do all this.

A carburetor is a device for mixing air with fuel. As a result of its operation, atomized gasoline mixed with air, ready for ignition, enters the combustion chamber of the engine at the right time. Despite the fact that the carburetor is one for several cylinders, the mixture always gets to the right place through the intake manifold due to the well-coordinated system of operation of all internal combustion engine elements.

Problems

Some carburetor problems can be solved by adjusting the choke, mixture, or idle, while others require repair or replacement. Often the carburetor membrane wears out, stops pumping gasoline into the chambers.

When the carburetor fails, the engine will perform poorly under certain conditions. Some problems of carburetor systems lead to engine breakdown, it cannot normally idle without outside help (for example, pulling the choke or constant gasping). The most common problems occur during the cold season, when the engine is most difficult to work. And a carburetor that performs poorly on a cold engine may function normally when warm (this is due to problems with coking channels).

It is worth noting that the carburetor for a walk-behind tractor is the same in composition as an automobile one. The difference is in the number of elements and their sizes. In some cases, carburetor problems can be resolved by manually adjusting the mixture or idle speed. To this end, the mixture is usually adjusted by turning one or more screws. They have needle valves. These screws allow the needle valves to be physically repositioned, which means that the amount of fuel can be reduced (lean) or increased (rich) depending on the situation.

Carburetor device

To this day, we have received mainly float models - the latest and most advanced. So on most cars you can find exactly them.

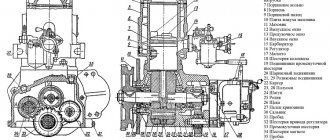

The device of the float carburetor: 1 - adjusting screw of the starting device; 2 - lever pin 24, included in the groove of the lever 3; 3 - air damper control lever; 4 - screw for fastening the air damper drive rod; 5 - adjusting screw for slightly opening the throttle valve of the first chamber; 6 - throttle lever of the first chamber; 7 - axis of the throttle valve of the first chamber; 8 - throttle actuator lever of the second chamber; 9 - adjusting screw for the amount of idle mixture; 10 - axis of the throttle valve of the second chamber; 11 - throttle lever of the second chamber; 12 - pipe suction of crankcase gases into the throttle space of the carburetor; 13 - throttle valve of the second chamber; 14 - outlet holes of the transition system of the second chamber; 15 - throttle body; 16 - atomizer of the main dosing system of the second chamber; 17 - small diffuser; 18 - housing of the fuel jet of the transition system of the second chamber; 19 - spray accelerator pump; 20 - fuel supply pipe to the carburetor; 21 — econostat atomizer; 22 - air damper; 23 - the rod of the starting device; 24 - air damper lever; 25 - starter cover; 26 - lever pin 24, acting from the rod 23 of the starting device; 27 - axis of the air damper; 28 - carburetor cover; 29 - a tube with a fuel jet econostat; 30 - fuel filter; 31 - needle valve; 32 - emulsion tube of the second chamber; 33 - float; 34 - main fuel jet of the second chamber; 35 - bypass jet of the accelerator pump; 36 - throttle actuator lever; 37 - accelerator pump drive lever; 38 - accelerator pump diaphragm; 39 - adjusting screw of the quality (composition) of the idling mixture; 40 - vacuum intake pipe of the vacuum ignition timing controller. 41 - carburettor body. 42 - electromagnetic shut-off valve; 43 - adjusting screw for additional air for factory adjustment of the idle system; 44 - aperture of the starting device.

The float carburetor consists of many elements.

- Float chamber, which is responsible for maintaining a certain level of fuel.

- A float with a locking needle designed for automatic dosing of the fuel level in the float chamber.

- Mixing chamber in which the main mixing of atomized (finely dispersed) fuel and air takes place

- Diffuser - a narrowed area, passing through which the air flow accelerates its movement.

- A nozzle with a jet connecting the float and mixing chambers, through which fuel passes directly to the diffuser.

- Throttle valve - regulates the flow of the mixture entering the cylinders.

- Air damper - regulates the flow of air entering the carburetor. Thanks to it, you can make the mixture "poor", normal or "enriched".

Scheme of the dependence of power on the amount of air in the fuel mixture

The diagram shows that a normal mixture is when there is about 15 times more air than fuel. Under such conditions, there will be complete combustion of gasoline and maximum power. - Idle system - delivers fuel bypassing the mixing chamber when the throttle is fully closed. Through special channels, gasoline and air pass into the throttle space.

- Economizers and Ecostats are devices for additional fuel supply when the engine is running at maximum loads. At the same time, economizers have forced control, and ecostats work from air rarefaction.

- Fuel suction - a system of forced enrichment of the fuel mixture. By pulling the lever, the driver slightly opened the throttle, as a result of which the air passed more intensively through the mixing chamber and took more fuel. It turns out an enriched mixture, convenient for starting a cold engine.

The principle of operation of the carburetor

After watching the video below, you will clearly see the device and the principle of operation of the carburetor in different operating modes. The video is old but still relevant today. Do not be lazy and watch to the end if you want to fully understand the topic.

Well, let's summarize below - the work of all float carburetors is carried out according to a typical scheme.

- Gasoline is pumped into the float chamber through the fuel line from the tank to the desired level, which is regulated and maintained by a float and a locking needle.

- The atomizer, located in the lower part of the float chamber, with the help of a jet, transfers a strictly metered portion of fuel to the mixing chamber. At the same time, the fuel flow is atomized for better mixing with air and combustion.

- The fuel from the atomizer is diffused over a diffuser, which is designed to create a fast airflow and better mix it with the already atomized gasoline.

- The mixture of fuel and air enters the throttle valve, which is directly connected to the gas pedal. The more fuel the engine needs, the more the throttle is open and the more active the carburetor works.

- From the carburetor, the air-fuel mixture passes through the intake manifold to the cylinder in which the piston is currently lowering with the simultaneous opening of the intake valve.

- The piston works like a pump, drawing in the mixture already prepared in the carburetor.

Despite the rather simple principle of operation, a well-tuned carburetor provides excellent power output from the engine, good fuel economy and system reliability.

A bit of history

Early developments at the dawn of the era of engine building used lighting gas as a fuel. Such engines at an early stage simply did not need a carburetor. Light gas entered the cylinders due to the rarefaction that was formed during the operation of the engine. The main problem of such fuel was its high cost and a number of difficulties in the process of use.

The second half of the 19th century was the period when inventors, engineers and mechanics around the world tried to replace expensive lighting gas with a more economical, cheap and affordable type of fuel for an internal combustion engine. The best solution was to use the liquid fuel familiar to us today.

It is worth considering that such fuel cannot ignite without the participation of air. To prepare a mixture of air and fuel, an additional device was required. Not only that, but it was also necessary to mix air with fuel in the right proportions.

To solve this problem, the first carburetor was invented. The device saw the light in 1876. An early model of the carburetor was created by the Italian inventor Luigi De Christophoris. According to its design and principle of operation, the first carburetor had a number of significant differences from more modern analogues. To obtain a high-quality fuel-air mixture, the fuel in the first device was heated, and its vapors were mixed with air. For a number of reasons, this method of forming the working mixture is not widely used.

Developments in this area continued, and a year later, talented engineers Gottlieb Daimler and Wilhelm Maybach created the design of an internal combustion engine that had a carburetor that worked on the principle of fuel atomization. This device formed the basis for all subsequent developments.

Modernization

The main direction of further work of engineers was the maximum automation of all processes of mixture formation. The best minds of many companies producing cars and related equipment worked to improve the design of the carburetor. For this reason, you can find a great variety of simple and complex carburetor models from numerous world manufacturers.

Further development

Carburetors began to be actively replaced by injection systems only at the end of the 20th century. Until that time, the design of the carburetor was intensively improved. Electronically controlled carburetors have become the latest evolution of carburetor injection. In such carburetors, there were several solenoid valves, the operation of which was controlled by a special control device. For example, we can mention the Hitachi carburetor brand. The design had almost 5 valves, and the dampers were controlled electronically.

The latest generation of structurally complex carburetors is perfectly demonstrated by the already mentioned model of the Hitachi carburetor. This carburetor was installed on Nissan cars in the very late 80s and early 90s. The complexity of this generation of carburetors lies in the large number of auxiliary devices, especially if you compare the Hitachi product with the primitive Solex that was installed on the VAZ.

Auxiliary devices were responsible for stabilizing the operation of the carburetor in various modes. Such modes and features of operation include a sharp release of gas, idle mode during idle time in a car with an automatic transmission, alignment and stabilization of the speed of the power unit after turning on the air conditioner, as well as many others.

The carburetor of the latest generations, brought to perfection, basically consisted of numerous devices. We will name just a few of them for reference:

- Outdoor air temperature control system;.

- Intake manifold heater;

- Fuel cut-off valve;

- Mixture enrichment valve;

- Bimetallic air damper spring in the throttle opening mechanism;

- Fast idle system, etc.;

Such devices are among the latest "electronic" carburetors. Additional elements in these models were made in the form of separate analog devices. The devices were controlled by the simplest electronics or worked on the principle of self-regulation (bimetallic spring).

It is noteworthy that simple mechanical carburetors are very versatile devices and can be installed using an adapter on different car models. An excellent example is the same well-known Solex carburetor to domestic motorists.

Types of carburetors

The predecessors of the already considered float carburetor were membrane-needle and bubbling. These are already outdated designs that today you will not find on everyday cars (but these rarities still exist on “old cars”).

The membrane-needle carburetor consists of several chambers separated by membranes. The membranes are supported by springs of a given stiffness and are interconnected by a rod. The membrane chambers have an outlet to the mixing chamber and are also connected to the fuel supply channel. The movement of the rod actuated the membranes of the chambers, forcing them to pump fuel into the mixing cavity. Yes, the system is somewhat cumbersome and slow to respond to changes in engine operation, but at the same time reliable to such an extent that it was installed on aircraft engines.

Scheme of a membrane-needle carburetor

The bubbling carburetor is the first design and the first attempt to create such a device. It was a blind cover that covered the gas tank at some distance from the fuel. Two pipes were brought to the cover: one inlet for air, the second to the engine. The air, passing under the cover, was saturated with gasoline vapors and in this form was sent to the combustion chamber. This is the first device that is designed to work with fuel vapors.

Diagram of a bubbling carburetor: 1 - pipeline; 2 - hole in the float chamber; 3 - diffuser; 4 - atomizer; 5 - throttle valve; 6 - mixing chamber; 7 - jet; 8 - float chamber; 9 - float; 10 - needle valve.

The classification of other types of carburetors depends on the design features. According to the nozzle cross section, devices with a constant vacuum (models made in Japan with the highest performance characteristics), with a constant nozzle cross section (carburetors manufactured in the USSR and the Russian Federation) and with spool throttling (horizontal carburetors, intended mainly for motor vehicles) are distinguished.

According to the direction of movement of the finished mixture, designs with horizontal and vertical flow are distinguished (of the latter, the downflow system turned out to be the most effective).

Float carburetors may have one or more mixing chambers. Single-chamber devices were in use until the 1960s, when the development of engines required an increase in carburetor capacity.

The creation of multi-chamber carburetors with multiple throttle valves solved this problem. Varieties appeared: carburetors with the simultaneous opening of two throttle valves, each of which fed certain cylinders, and carburetors with the sequential opening of two dampers, which were connected to the entire engine and worked in accordance with its mode.

As engine power grew, so did carburetors. Three- and four-chamber types appeared, several carburetors were installed on the car, various options for preparing the fuel mixture were set up (for example, an over-enriched mixture was made in one chamber, and a lean mixture was made in the other two).

The principle of operation of the carburetor engine

The principle of operation of a carbureted engine is relatively simple and consists of four strokes, which coincide with the movement up and down in sequence one by one.:

- The first stroke is the intake; the intake valve opens and a new mixture is delivered to the cylinder from the power system.

- The second cycle is compression; The piston compresses the combustible mixture in the combustion chamber. All valves are closed.

- The third measure is expansion; the compressed combustible mixture ignites from the spark plug. The mixture is burned quickly enough with a constant volume, which corresponds to the volume of the compression chamber itself. This is the main feature of the carburetor engine. When burnt out, gases are formed that move the piston downward and transmit movement to the crankshaft.

- Fourth cycle - injection; The crankshaft rotates and ejects exhaust gases from the cylinder through the slightly open exhaust valve.

This completes one working cycle of the carburetor engine.

During the first stroke, the intake valve is already open when the piston approaches, and due to the high speed of the piston, the working mixture moves towards the cylinder and for some time when the piston rises in the second stroke.

The spark ignites the mixture before high pressure builds up in the cylinder. In the fourth stroke, the valve releases exhaust gases, which cleans the cylinder even before the piston approaches. However, the release of gases does not stop even after the piston approaches. Then a new portion of the working mixture is launched, which again passes into the cylinder.

It follows that in operation between the first and fourth cycles, the intake and exhaust valves open at the same time, that is, the valves overlap. During the moment of overlap, the cylinder is cleaned and a rarefaction occurs in it, which helps to fill the cylinder with a combustible mixture at the first stroke more profitably.

Advantages and disadvantages of carburetors

About the horrors of the eternal repair of the carburetor, only the deaf have not heard. But what really? What are the advantages of this device and does it make sense to deal with it at all? Oddly enough, it will sound in our technological age, but the carburetor has several serious advantages.

- Simplicity of design. No, it's not that this is a very simple mechanism. But compared to the electronic stuffing of today's cars, the carburetor is an order of magnitude easier to repair, maintain and even operate. Most carburetors do not have any electronics, only mechanical devices, which means that a person with “straight hands” can repair and maintain it himself. This is well remembered by the "old guard" - our parents, who are used to delving into their "beloved" Zhiguli and Zaporozhets.

- Maintainability. Everything that breaks in the carburetor can be fixed without "extra blood". The necessary spare parts can be bought (there are manufacturers who still produce repair kits. And why not?).

- When working with low-quality fuel, the carburetor is much more tenacious and stable than the injector. And in general, it is not too picky about cleanliness, and if it gets clogged, it is subject to simple cleaning at home (“garage”) conditions.

- A small amount of water that gets into the carburetor will not harm it, unlike the injector. True, over time it will require cleaning and calibration.

- And, finally, the carburetor does not require connection to the mains, sensors, processor and other "joys" of civilization. It runs solely on the energy of the air sucked in by the engine, which means it was the best option for installation on old cars where there was no electronics at all.

But there are also disadvantages from which carbureted cars eventually left the global automotive arena.

- Technology demanded a fuel delivery system with flexible adjustments, rather than constant parameters, in order to minimize fuel consumption (which no one had thought much of before). Therefore, the carburetor was replaced by an injection system, which is still being developed and improved.

- The second significant disadvantage is the dependence of the carburetor on weather conditions. In the cold season, condensate collects inside, which interferes with work; in winter, there is a risk of icing on the inside. At the same time, the summer heat also does not allow it to work stably due to active evaporation - failures in the supply of the mixture begin.

- Well, the third drawback is much lower environmental performance compared to the injector. In the modern struggle for the environment, carbureted cars simply do not stand up to criticism, since their harmful emissions are much higher.

The main malfunctions of carburetors and their causes

Malfunctions in the carburetor are reflected in the operating mode of the engine, and it is from it that it can be determined that not everything is normal with the fuel supply system.

- It is difficult to start a cold engine - most likely, problems in adjusting the throttle. It is necessary to adjust the damper drive so that it closes completely when the suction is extended, or adjust the starting clearances.

- An unheated engine starts and immediately stalls when the suction is fully extended - the problem is again in the throttle actuator. Either the gaps are incorrectly adjusted, or the telescopic rod does not work and the damper does not open.

- A warm engine is difficult to start - the fuel level in the float chamber is not adjusted, the float mechanism or valve needle is out of order, as a result of which the fuel level is above normal.

- Unstable operation of the engine at idle - there may be several reasons, and the main one is the adjustment of the idle system. Other reasons - the idling econostat drive does not work or the shut-off valve does not work, the jets are clogged, air is leaking, the float in the float chamber does not work normally

- When the throttle is opened, there is no increase in power - too rich or lean mixture due to leaky fixation of the accelerator pump atomizer.

- Low acceleration dynamics - lack of fuel due to a lean mixture or shutdown of the secondary chamber.