The nipple is an integral part of the car wheel. It serves to inflate the tire with air and hold the pressure inside the tire. During operation, the valve is exposed to aggressive environmental influences. This leads to its damage and accelerates natural aging. As a result, the nipple may need to be replaced to resolve air leakage problems. In most cases, it can be done without removing the tire, but sometimes disassembly of the wheel is still required.

Appearance and design description of the nipple

Types of nipples

The oldest type of nipple is Dunlop. It was used on cars only at the dawn of the car building. At the moment, it is practically nowhere to be found. You can see the Dunlop valve only on retro cars and bicycles.

It is extremely rare to find a Presta nipple on cars. He switched to bicycles. Nevertheless, such a nipple can be seen on some cars produced in the middle of the last century. Also, such a nipple is used on light mopeds and scooters.

Nipples of various designs

The most popular on machines is the Schroeder nipple. Its design proved to be the most convenient and reliable. Therefore, the valve managed to conquer almost all cars.

Varieties of nipples

Nipples are of the following types:

- Shrader or automotive nipple is the most common type of design today. In mechanical engineering, it acts as a standard, and other types are rarely used instead. Its distinguishing features include the fact that the diameter of the case is 8 millimeters.

- Presta or sports nipple - used on the wheels of modern road and mountain bikes. Its diameter is 6 mm.

- Dunlop - rubber tubing, which used to be very common. Although they have long been out of use by bicycle tire manufacturers, they can still be found in the store. Under this type of nipple, a hole with a diameter of 8 millimeters is created in the rim. Previously installed on all bicycles that were produced in the USSR.

Now more about the features of each type:

- The advantages of the automotive type include the fact that it is very common, which means that almost any automobile pump can be used to inflate a wheel. However, pumps that do not have a clamp cannot be used, as there is no lock wheel. The design features include the presence of a valve, which, when pressed, releases all the air. There are also options that can be unscrewed completely and the air will come out almost instantly. The cap in this case protects the valve structure from various external influences, but does not affect the tightness.

- Nipples for mountain and road bikes. A similar design has a locking copper cap that must first be unscrewed before inflating the tire. Many rims are high profile and this requires a longer nipple design. The considered embodiment is lighter, more modern and technologically advanced, but at the same time fragile. Therefore, for protection, it is imperative to use a cap.

Many bike pumps have adapters that allow you to inflate wheels with Shrader and Presta. At the same time, the type of nipple does not affect the type of wheel and its operation.

Varieties of nipples

Nipples used on cars can be made from various materials. The most popular options are listed in the table below.

Table - Material options for the manufacture of the nipple

| Material | Note |

| Rubber | The body is completely made of durable rubber. The internal mechanism is made of non-ferrous metal. |

| All metal | Made from brass or chrome plated steel. Its replacement is impossible without removing the tire, as it is fixed with a nut. |

| rubber-metal | Composed of a combination of chrome steel, brass and rubber. |

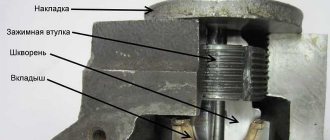

rubber-metal valve

All of the above valves are successfully used on cars. The rubber nipple is used on low-speed passenger cars. It has little effect on the weight distribution of the wheel. One of its main advantages is low cost and ease of installation without removing the busbar.

The rubber nipple cannot withstand the loads created by centrifugal force at high speed. Its hull cracks and collapses. Therefore, rubber-metal valves can be found on most tubeless tires.

On dynamic machines and commercial vehicles, the nipples work with significant pressure in the wheel and under a significant influence of centrifugal force. Therefore, all-metal valves are installed on such cars.

Automotive nipples have a variation in the size of the seats. Manufacturers decided to come to a common standard. Therefore, on most modern machines, the nipple socket has a diameter of 8 mm.

Despite the unification of the seat on some machines, the holes for the valve have a diameter of 4, 6.11.3 or 15.7 mm. All branded nipples have a marking that describes the size of the seat.

bicycle nipple

To implement this idea, it was necessary to find a way to supply air to the created chamber so that after inflating and creating a certain pressure in this chamber, the air would not go back out. It was the nipple that became the solution to this problem.

In the modern sense, a nipple is a connecting type tube that is used to temporarily or permanently connect a pipeline to a chamber. It is worth noting that the specially shaped nuts used to connect the spokes in a bicycle rim also came to be called a nipple.

Nipples are used in many industries, and depending on the purpose, they have a different design, but the principle of operation remains the same. Dunlop is considered to be a bicycle version. A similar design included the presence of a rubber tube as a check valve.

At the same time, the thread diameter was significantly smaller than the diameter of the vehicle version. In order to inflate such a tire, it was necessary to have a special pump. There are practically no cameras with similar nipples on sale.

Presta is considered a popular version. It is smaller than a car and at the same time more fragile. In this case, it will not work to use a car pump, but you can purchase an adapter.

Principle of operation

Usually, in order for the design in question to perform its basic functions, it is equipped with a one-way valve, which ensures the tightness of the high-pressure area containing air. The rest of the design features depend on the features of the nipple.

Nipple repair

When a nipple fails, it does not always need to be replaced, since installing a new spool sometimes helps solve the problem. Some cars have metal valve caps, on the back of which there is a special key. With it, you can easily unscrew and twist the spool.

Metal cap of the nipple with a key for unscrewing the spool

Most modern cars have plastic caps that prevent the spool from being unscrewed. In this case, it is recommended to purchase a special key.

Experienced car owners recommend using improvised means to unscrew the spool. For these purposes, tweezers or a pointed fork are suitable. You can also make a special key from a strong wire.

homemade key

How to unscrew the nipple

In the past, when a car left the factory, steel caps were installed on its wheels. Their reverse side was an original key - two half rings, which were separated by a slot. The key could freely twist or unscrew the nipple. To do this, it was necessary to get a slot into its hole.

Recently, wheels have been produced with plastic caps. They are not designed to work with nipple designs. A special key can be freely purchased at any auto shop. Its cost does not exceed 10-15 rubles.

Each driver must have at least one nipple key in stock. It will help to quickly replace the nipple on the road.

Nipple replacement with disassembly

Replacing the nipple with a split is required for tube tires. In this case, the valve is a constituent element of the chamber and changes exclusively with it.

Replacing with disassembly may also be necessary in the case of tubeless tires. The reason for this is the strong sticking of the old valve or its all-metal manufacture. To replace in this way, it is recommended to follow the instructions below.

- Secure the vehicle with the parking brake if work is being carried out on the front axle.

- Place wheel chocks to prevent unintentional movement of the vehicle.

- Loosen the fasteners of the wheel on which the nipple is being replaced.

- Jack up the car.

- Place a stop to prevent the machine from falling if the jack breaks.

- Unscrew the wheel mount and remove it.

- Remove the cap from the nipple.

- Release the remaining air. To do this, you can press the air valve with a screwdriver or release excess pressure, for example, using a pressure gauge.

- Disassemble the wheel.

- Remove the damaged nipple. If necessary, unscrew the eo fasteners.

- Install a new valve.

- Assemble everything in reverse order.

- Inflate the wheel to the recommended pressure.

- Check for air leaks.

When to Replace a Valve

Given that the valve on the wheel disk is considered a consumable item, it changes quite often, and when the first signs of wear appear, the old product must be urgently disposed of and a new nipple installed in its place. To understand exactly when its service life has expired, the owner of the car must pay attention to the characteristic features.

If a motorist loaded the car at least once with an unforeseen load, then the valve may not withstand, the rubber valve in the nipple will break, and the air will start to come out, which also indicates the need to update the product.

The last thing that can render the valve on the wheel unusable is the aggressive influence of the environment. Active ultraviolet rays, frequent sudden temperature changes, the presence of salt-based reagents in winter and other factors contribute to the destruction of polymer parts and corrosion of the metal components of the product, after which the valve becomes unusable.

Thus, when the car has been operated without complaints for more than 5 years, then the nipple must be changed along with the tires, at least for preventive purposes.

Set for changing the nipple without removing the bar

Experienced drivers know how to replace the nipple without stripping the ramp. This requires a simple set of tools that can be made from improvised means. You can see the special accessories in the photo below.

Homemade valve replacement tools

If you do not want to mess with the manufacture of tools, you can purchase a ready-made kit for removing the nipple. It has a low price and allows you to easily remove and insert the nipple. An example of such a set is shown in the image below.

Complete set for removal and installation of the valve

The set includes:

- hook hook;

- conical tube;

- threaded pusher.

Standard nipple replacement kit

Valve Replacement Recommendations

Replacing the entire valve on a tubeless tire assembly is impossible without removing the rubber from the wheel, and this procedure is performed exclusively within the walls of the service station, since a private individual almost never has professional equipment to carry out this work. However, when extreme conditions require the driver to do the entire process himself, he should be guided by the following step-by-step instructions:

- It is necessary to slightly unscrew each of the nuts on the wheel with a defective nipple.

- Take a jack from the trunk, assemble it, substitute it under the car body and hang it above the ground so that the wheel rotates freely.

- All nuts are carefully unscrewed to the end, after which the wheel is completely removed from the hub.

- Remove the cap from the valve, press on the spool of the nipple and hold it until all the air comes out.

- The wheel is disassembled with a crowbar or a long screwdriver, when the driver picks up its edges along the circumference of the disk. Care must be taken here, as there is a risk of damage to the metal or rubber components of the disc and tire with the sharp ends of improvised means.

- With the help of pliers, the old valve is pulled out, and if pieces of rubber are stuck on the surface of the rim, they must be carefully removed with a knife with a good sharpened blade.

- Take a new product and treat it with a lubricant to improve glide.

- The tire valve is inserted exclusively from the inside of the rim, and from the opposite end it is securely fixed to it using the same pliers.

- The tire is put back on the disc, the wheel is inflated until the pressure required for this car model is reached using a pump with a special barometric sensor, and subsequently attached to the hub studs with nuts. It is important here not to tighten them to the end, since the car may fall off the jack from a large effort.

- The jack relaxes and the car gently lowers to the ground, and then with great effort you need to tighten all the nuts without missing a single one.

Self-replacement valve

Replacing a nipple is a rather responsible procedure that can not only harm the rim and tire, but in the end turn out to be ineffective, since, without knowing all the intricacies of the procedure, a motorist can install the product with a warp, press it against the rim not tightly enough, or perform other errors.

Thus, in order to achieve the required quality and durability in the use of the product, you should still contact tire fitting professionals, as they not only have extensive experience in solving these problems, but also have the necessary equipment, which ultimately guarantees quality and saves the car owner from extra spending.

Source kolesa.guru

Now I will campaign for tubeless wheels, which I consider the second great gift of bicycle marketers (the first gift is the transition to a 1x system, one star in front). I myself got to tubeless only last year, along with a return to the MTB theme.

To everyone who more or less seriously rides offroad and is still on cameras, I recommend that you carefully read the text below - only practice, only relevant info, no lyrics about UST wheels and ghetto tubeless. Perhaps I can convince you to look in that direction.

Well, the rest can also be found for development. This will only be about mountain bikes and hard off-road use, although there are also advances in this direction on the highway, but more on that another time.

In this article, we will talk about what bicycle camera nipples are, what they are, and how to choose the right device for yourself, at first glance, a simple device.

A nipple is a specially shaped nut for attaching spokes to a bicycle wheel rim. The temporary connection nipple is usually equipped with a one-way valve and is used in all kinds of pneumatic (inflatable) devices, in particular, bicycle tires.

There are three types of bicycle nipples:

- Presta

- Dunlop

- shrader

Presta cycling

Presta (denoted as FV - French Valve, French or Sports, or SV - Sclaverand Valve) nipple - is becoming more and more popular. Recently, such nipples have been used not only on cyclocross, road, mountain racing and hybrid bikes, but also on mid-level models. Available in various lengths: 42, 60 and 80 mm. They are used in tubeless tires, and can also be used in narrow and lightweight rims. With a special extension nozzle they can be used in solid wheels where a very long nipple is needed. With a width of only 6mm, the nipple is the thinnest bicycle nipple. Its weight is 4-5 grams less than the Shrader type nipple. The problem of incompatibility of nipples was solved by pump manufacturers. 95% of these devices on the cycling market are universal. In order to inflate the Presta chamber, you need to unscrew the pump nut and turn the rubber bushing over. Presta/Shrader adapters are also available, thanks to which you can use a regular car pump.

| Presta nipple (click image to enlarge) |

Rushing too hard or using a poor quality pump can break the valve in the Presta nipple. Good expensive cameras usually use a replaceable screw-in valve.

Presta nipple rims with an internal width of 17mm can be drilled with an 8mm Schrader drill and then bevelled - this is considered to have little effect on strength, but the rim warranty will no doubt be voided.

Shrader automotive

Schrader (AV - Auto Valve or automotive) is the most common type of nipple. It has the form of a threaded cylinder with a diameter of 8-8.5 mm. The standard length is 40 mm, but they are available in lengths of 60 mm. The advantage of such a nipple is the prevalence. In the absence of a pump, you can always pump up the wheels at a car gas station, tire fitting, or by agreement with the driver. They are used on hybrids and mountain bikes of the lower and middle levels, as well as on bicycles for extreme cycling. Also used in rear shock absorbers and bicycle forks.

The big advantage is that almost all bike pumps are compatible with both Presta and Schrader.

| Schrader nipple (click image to enlarge) |

Dunlop

Dunlop is an obsolete type of nipple that is becoming less and less common on bicycles. Used on Soviet bicycles. Nipple for hole in rims 8 mm. Dunlop nipple chambers can be pumped with a Presta nipple pump. A tube with a Dunlop nipple can be mounted on a rim with a Schrader hole without any additional manipulation. Also, the end threads of Presta and Dunlop nipples are the same, so the pumps (and caps) are always compatible.

| Dunlop nipple (click on image to enlarge) |

Nipples also differ in their design:

Threaded metal - used in relatively expensive cameras (Schwalbe, Continental, Nokian, etc.). Most often, they have a fixing nut, which prevents the nipple from moving and sinking during inflation, which ensures high reliability.

Rubberized - used in cheap cameras, less reliable and convenient than metal ones. Higher risk of damage to the nipple on the edge of the hole in the rim or separation due to inaccurate inflation.

Published: 06.08.2013

37155 views

Tired of driving around your city? Our bike tours are much more interesting! Need a bike? A great way out is to buy a bike from our bike shop! Broken bike? It's not a problem - we have bike repairs in our store. To be in shape in winter? buy a simulator.