P5ZV7385_new size

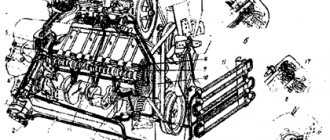

In terms of dimensions, the D946 engine is comparable to European diesel engines with a volume of 12–13 liters, and here a lot depends on the dimension and center distance.

In terms of dimensions, the D946 engine is comparable to European diesel engines with a volume of 12–13 liters, and here a lot depends on the dimension and center distance.

It would be possible to buy a license and technological assembly lines, as the GAZ Group did with the Renault Trucks DCi 11 engine for the Yaroslavl Motor Plant. But there the engine was originally of the Euro‑3 level, although with the possibility of fine-tuning to Euro‑4.

But in Chelny they are preparing for production their Euro-5 engines - the traditional V-shaped "eight" KAMAZ-740.735-400 and KAMAZ-750.10-400. Why spend extra money and time developing an in-line six-cylinder engine - just for the sake of it being?

The fact is that the longtime supporters of V‑shaped diesel engines for Mercedes-Benz and Scania trucks are also planning to curtail their production in favor of inline “sixes” for a reason. This is primarily due to the layout features of Euro 6 and higher engines. To neutralize exhaust gases, to optimize the settings of electronically controlled diesel fuel systems, a combination of exhaust gas recirculation (EGR), injection of an aqueous urea solution (SCR) and a regenerated particulate filter will not be enough. Experts agree that these systems will have to be supplemented with a turbocompound. That is, the installation of another turbine, which, through a viscous coupling and a reduction gear, additionally, without fuel consumption, twists the crankshaft. Free power allows you to strangle the engine for the sake of the environment without any problems.

Overhaul

order a repair

Overhaul of the KamAZ-740 engine is a rather complicated procedure that requires knowledge of the design, technical standards and special equipment for these operations. There are instructions for the overhaul of power units, which are developed by the manufacturer, they accurately spell out all the details of the process.

The sequence of actions for carrying out restoration operations on the KamAZ-740 engine:

- To begin with, a faulty motor is disassembled to determine defects.

- The next step is troubleshooting. This includes diagnostic work on the crankshaft, cylinder heads, camshaft, water and oil pumps. When carrying out repair and restoration work, the high-pressure fuel pump for fuel supply is necessarily restored.

- The next stage of the repair of the power unit is the boring of the block and the crankshaft. It is worth noting that the KamAZ crankshaft is a strong enough part, so this is not always required. But with the block, things are usually much worse. In any case, you will have to bore the cylinders, but this does not always help. So, if the motor is over 20 years old, then the only solution is the block sleeve.

| Name / Repair | 1 | 2 | 3 | 4 |

| Crankshaft | 0.25 mm | 0.50 mm | 0.75 mm | 1.00 mm |

| Cylinder block | 120.5 mm | 121.0 mm | 121.5 mm | ST - sleeve |

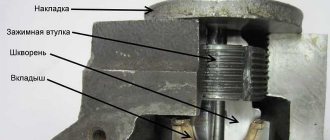

- An integral stage in the restoration of the motor is the repair of all heads, of which KamAZ has eight pieces. So, guide bushings often change, which are first turned on a lathe. The chamfer is removed and adjusted on the valves, and the seats are subjected to cutter.

- The next step is polishing the camshaft cams. This is done on a lathe using a special paste and sandpaper.

- Next comes the stage of repairing the water and oil pump. Engine rebuilders are reluctant to repair these parts, but due to the high cost, they have to to keep customers. As mentioned earlier, only some elements of the products are subject to replacement. So, the impeller, shaft assembly, cuff and bearings are changed.

- Before proceeding with the procedure for laying the crankshaft, it is necessary to carry out the balancing process. A clutch is attached to the crankshaft and rotated by installing special weights. If this procedure is not carried out, then during operation the shaft will be unbalanced, which will lead to the breaking of the yokes and connecting rods with liners.

- Assembly can rightly be considered the last step. This process is quite long, since it takes almost a whole day. The crankshaft is laid, and the process of "ligation" goes through. This is the procedure for connecting the crankshaft to the piston group and installing liners, both main and connecting rod. Next is going to the oil pump and pump. All small details are collected. The last to install are the block heads, valve covers, injection pump and exhaust system.

- After the engine is assembled, it must be run in. This is only done when hot. The power unit and the exhaust system are connected to the power unit, and then it is started by adjusting the speed, and the valve clearances are periodically set.

After the KamAZ power unit is assembled, it is installed on the car and tested on the go.

Repair and maintenance of KamAZ-740 engines is quite simple and does not require any special skills and abilities of specialists. Unlike Western counterparts, the KamAZ engine has simple design features and does not have complex electronics.

order a repair

P5ZV7378_new size

The flywheel housing is made according to the SAE1 standard - here you can put not only the Allison Transmission hydromechanical transmission, but also any ZF box, up to Traxon.

The flywheel housing is made according to the SAE1 standard - here you can put not only the Allison Transmission hydromechanical transmission, but also any ZF box, up to Traxon.

The lead bronze bushings will have an additional anti-friction wear layer (PVD coating) that will be applied by ion-vacuum sputtering. Moreover, such plain bearings will be manufactured at the Dimitrovgrad plant of liners, which was recently acquired by Federal-Mogul.

Based on the new KAMAZ-910.10 engine, various modifications will be created - with a capacity of 380, 400, 450, 500 and 550 hp. With. at 1900 rpm. Torque - from 1700 to 2540 N m, with a shelf in the range of 1100-1400 rpm.

In Europe, and even more so in Russia, the power range of 440–480 hp is most in demand. With. - both on vehicles for long-distance transportation, and on trucks for construction purposes, up to four-axle vehicles.

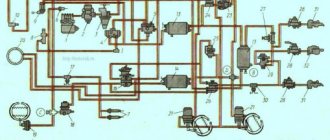

Engine cooling system KAMAZ 740

A closed-type liquid system with forced circulation is responsible for cooling the Kamaz 740 diesel engine. Its main elements:

- Radiator,

- Water pump,

- thermostats,

- Fan drive fluid coupling and its switch,

- Expansion tank,

- Bypass pipes and fittings,

- Blinds.

Scheme of the cooling system Kamaz 740.

The centrifugal pump ensures constant circulation of the coolant in the system while the engine is running. First, the liquid is supplied to the water cavities of the left and right rows of cylinders.

During the cooling of the outer surfaces of the cylinder liners, the coolant enters the water cavities of the cylinder heads through the channels in the upper mating planes of the block.

After passing through the cylinder heads, the liquid is fed through the pipes to the thermostat and from there, depending on its temperature, it goes either to the radiator to reduce the temperature, or to the water pump, from where it goes to the next round into the cooling system.

The operating temperature of the coolant in the cooling system of the Kamaz 740 engine is 80-98 degrees C. Automatic thermostats and a fan fluid coupling switch are responsible for the thermal regime of the engine. And depending on the temperature, the fan turns on for additional cooling of the liquid or it is in circulation all the time if the temperature is within the lower limits.

How much is the item

The price of a turbocharger depends on the manufacturer and model of the engine. Domestic products for KAMAZ Euro-2 can be purchased for 14-17 thousand rubles. Czech and German units cost about 20,000 rubles, and their counterparts cost 15-16 thousand. The most expensive turbochargers on the market are the products of the American company Cummins. The price for them starts from 20 thousand rubles, and some models will be sold for 35-37 thousand.

Refurbished (used) turbines are much cheaper. They can be purchased at a price starting from 6,000 rubles.

Source

Types and classes

There are four categories of engines that comply with environmental standards on the modern market. Depending on these parameters, the type and brand of the compressor is selected. The table below shows this information.

Read more: English signal in the car

One of the ways to increase the power of a diesel engine is a gas turbine pressurization system. Its main element is a turbocharger. It is installed on the discharge manifold and is driven by the energy of the exhaust gases. The use of a turbine in KamAZ gives an increase in engine power of about 25%. These trucks use two-row V-shaped power units. Therefore, 2 compressors are installed - each on its own unit.

Constantly increasing requirements for environmental safety lead to the fact that manufacturers are forced to improve the design of engines and turbocharging systems. Therefore, when choosing a compressor and installing it yourself, you must take into account the model of the truck and the brand of the power unit.

How to install

Some owners of trucks with non-turbo engines mount units on their own to increase engine power. The installation of a turbine on a simple KamAZ is associated with the manufacture of the foundation, because such a place is not provided by the design. Most often they put one unit on both blocks. In most cases, Czech or German-made turbochargers are used.

Experts believe that before putting a turbocharger on KamAZ-740 (simple), it is necessary to change the crankshaft and piston group to reinforced ones. Otherwise, there will be problems with the engine, and then more parts will have to be replaced.

Such units are also installed on turbocharged engines: one instead of two. It is cheaper and the probability of failure is halved. Such an installation can be carried out both independently and contact the service. At a specialized enterprise, they will not only professionally perform the work, but also give a guarantee for their implementation. Many car owners find it much easier to install an engine of suitable power than to adapt a turbine to it, and to carry out the settings by trial and error.

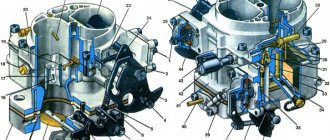

Purpose of turbochargers

During normal operation of a diesel engine, the air-fuel mixture in the combustion chamber is formed from the amount of air that "gravity" penetrated into the combustion chamber when the piston was lowered. However, in this case, the fuel does not burn completely and does not release all the energy stored in itself, and therefore the engine does not develop the power that it could develop. The simplest solution to the problem that comes to mind is to forcibly increase the volume of air entering the combustion chamber. How to do it? With a turbocharger.

Device

KamAZ turbochargers have a simple design. In fact, two elements interact in this device (a centrifugal compressor and a gas turbine). The first component part consists of such parts

- skeleton in the form of a snail;

- wheels with working blades of a specific configuration;

- holes through which air enters, supplied through a diffuser into the intake manifold of the motor.

The gas turbine has a similar structure, only instead of air, exhaust gases are fed into it, which are discharged into the exhaust system.

The wheels of both elements are connected using a central body, and the torque is transmitted through a roller. Consequently, the energy for the operation of the unit is produced from the exhaust gases.

1 - bearing; 2 - screen part; 3 - body; 4 - diffuser; 5 – sealing ring; 6 - nut; 7 - oil reflector; 8 – compressor wheel; 9 – screen of oil discharge; 10 - damper; 11 - skeleton of bearings; 12 - fasteners; 13 - adapter; 14 - gasket; 15 – turbine screen; 16 - wheel; 17 - body; 18 - sealant.

Read next: Gazelle coolant pump