Clutch master cylinder VAZ 2101

The stable operation of the clutch master cylinder (MCC) has a direct impact on the functioning of the gearbox and its service life, as well as the smoothness of gear changes. If the hydraulic drive breaks down, the control of the box becomes impossible, as well as the further operation of the car.

What is it for

The main function of the GCC is to briefly disconnect the power unit from the gearbox when shifting gears. When you press the pedal, pressure is created in the system, which acts on the clutch fork rod. The latter drives the release bearing, controlling the clutch.

How it works

The main components of the node are:

- outer cuff;

- sealing cuff;

- union;

- stock;

- return spring;

- frame;

- case for protection.

The GCC housing contains a return spring, cuffs, working and floating pistons

Principle of operation

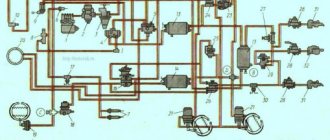

The hydraulic clutch consists of two cylinders - main and working (HC and RC). The principle of operation of the hydraulic drive is based on the following:

- The liquid in the HC enters through a hose from the tank.

- When acting on the clutch pedal, the force is transmitted to the rod by means of a pusher.

- The piston in the HC extends, which leads to valve overlap and fluid compression.

- After the liquid is compressed in the cylinder, it enters the hydraulic system through the fitting and is fed to the RC.

- The slave cylinder drives the fork, which moves the clutch with the release bearing forward.

- The bearing presses on the friction spring of the pressure plate, releasing the driven disc, after which the clutch is turned off.

- After the pedal is released, the piston of the cylinder returns to its original position under the influence of a spring.

The pedal moves the pusher, which, in turn, moves the piston and creates pressure in the hydraulic drive system

Where is

The GCC on the VAZ 2101 is installed under the hood near the vacuum brake booster and the master cylinder of the brake system. Near the clutch cylinder there are also tanks: one for the braking system, the other for the hydraulic clutch.

The GCC on the VAZ 2101 is located in the engine compartment near the vacuum brake booster and the master cylinder of the brake system

When is a replacement needed?

The elements of the cylinder wear out over time, which leads to interruptions in the operation of the mechanism. Repair or replacement of the GCC is needed when the following symptoms appear:

- airiness of the system;

- leakage of working fluid;

- wear of the cylinder components.

The presence of air in the hydraulic drive system disrupts the performance of the system, making it impossible to function. Air can enter the hydraulic drive through microcracks in the sealing elements of the cylinder or in the connecting hoses. If a system check reveals a constant lack of fluid in the expansion tank, the entire clutch mechanism must be inspected, since fluid can leave not only the master cylinder. If there is insufficient fluid in the hydraulic drive system, the necessary pressure to move the clutch fork cannot be formed. Such a problem will manifest itself in the inability to separate the motor and gearbox when the clutch pedal is pressed. If the leak is caused by wear on the connecting hoses, then replacing them is not a problem. If the problem is related to the GCC itself, then the product will have to be dismantled, disassembled and find out the cause, or simply replace the part with a new one.

When will we start repairing the clutch slave cylinder

The working clutch cylinder is traditionally located on the clutch housing. Its device does not fundamentally differ on different makes and models of cars, therefore the principle of replacing or repairing the clutch slave cylinder is the same, both on the Pajero and on the Zhiguli.

You need to know the device and its disassembly technology in order to repair the clutch slave cylinder with your own hands. This procedure is not as complicated as it might seem at first glance.

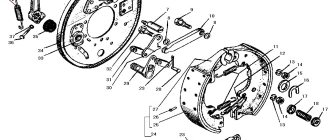

The cylinder body contains: a pusher, a piston, sealing rings, an air outlet, a spring.

Replacing the clutch slave cylinder assembly is a last resort, as existing repair kits are fully stocked with the most wear parts. Although, lately the quality of rubber parts has suffered very, very much.

The first sign of a clutch malfunction is a soft ride or failure of the clutch pedal. But, this is not a reason to start repairing the hydraulic drive. In order to calm your conscience, you need to bleed the clutch hydraulic drive.

But if during pumping you find air in the brake fluid, then you should think about where it came from. As a rule, the presence of air in the hydraulic actuator indicates a violation of the tightness of the rubber seals.

Clutch bleeding

Connect a hose to the bleeder screw on the working cylinder and lower its other end into a container with brake fluid. Then we fill the clutch master cylinder reservoir with brake fluid and press the pedal until air bubbles stop appearing.

If they do not stop, then we begin the repair of the hydraulic drive. Preliminary check for traces of external fluid leakage on both cylinders, the pipeline and at the joints.

Which one is better to put

On the VAZ 2101, it is necessary to install a clutch hydraulic actuator designed for the VAZ 2101–07. Cylinders designed to work in UAZ, GAZ and AZLK vehicles are not suitable for installation on a "penny". A similar situation with imported analogues. It will be quite problematic to introduce GCC from any foreign car, due to different fastening of the assembly, different threads and tube configuration. However, a hydraulic drive from a VAZ 2121 or from a Niva-Chevrolet is suitable for the "classic".

Manufacturer's choice

Today, there are many companies that manufacture clutch master cylinders. However, when choosing and buying the node in question, preference should be given to such manufacturers:

- JSC AvtoVAZ;

- Brik LLC;

- LLC "Kedr";

- Fenox;

- ATE;

- TRIALLI.

When choosing a GCC, it is better to give preference to well-known manufacturers

The average cost of a hydraulic clutch is 500–800 rubles. However, there are products that cost about 1700 rubles, for example, cylinders from ATE.

Table: comparison of hydraulic clutch actuators from different manufacturers by price and reviews

| Manufacturer, country | Trademark | Cost, rub. | Reviews |

| Russia, Tolyatti | AvtoVAZ | 625 | Original GCCs are made with high quality, they are more expensive than analogues |

| Belarus | Fenox | 510 | Original GCCs are inexpensive, made with high quality, popular among drivers |

| Russia, Miass | Brik Basalt | 490 | Improved design: the absence of a technological plug at the end of the cylinder and the presence of an anti-vacuum cuff increase the reliability of the product |

| Germany | AND THOSE | 1740 | The originals are of the highest quality. The price is tied to the EURO exchange rate |

| Germany | HORT | 1680 | Original GCCs are reliable and durable in operation. The price is tied to the EURO exchange rate |

| Russia, Miass | Cedar | 540 | The original GCCs do not cause any particular complaints |

Bleeding the clutch

In order to eliminate the possibility of failure of the clutch mechanism, after the repair is completed, the hydraulic drive system must be pumped. To carry out the procedure, the car must be installed on a flyover or inspection hole, and also prepared:

- brake fluid;

- wrenches for unscrewing brake pipes;

- rubber tube of suitable diameter;

- transparent container.

What liquid to fill

For classic Zhiguli, the plant recommends using RosDot 4 brake fluid in the clutch hydraulic system. A 0.5-liter container will be enough for repairs. The need to fill the liquid may arise not only during repair work, but also when replacing the liquid itself, since over time it loses its properties.

It is recommended to fill the clutch system of the classic Zhiguli with RosDot 4 brake fluid

How to bleed a clutch

Work is best done with an assistant. The liquid level in the tank should be under the neck. We perform the following steps:

- We pull one of the ends of the hoses onto the fitting of the clutch slave cylinder, and lower the other into the container.

- The assistant presses the clutch pedal several times until it becomes tight, and holds it in the depressed position.

The assistant, who is in the cabin, presses the clutch pedal several times and keeps it pressed - We unscrew the fitting and lower the liquid with air into the container, after which we twist the fitting.

To bleed the hydraulic drive system, it is necessary to unscrew the fitting and release the fluid with air bubbles - Repeat the procedure several times until air is completely expelled from the system.

Video: pumping the clutch on the classic Zhiguli

In the process of pumping, the fluid from the clutch reservoir will leave, so its level must be monitored and topped up as necessary.

In the process of bleeding the clutch, you need to monitor the fluid level in the tank and top it up in a timely manner

To bleed the clutch or brake system, I use a transparent tube, which allows you to visually assess whether there is air in the fluid or not. There are situations when you need to pump the clutch, but there is no assistant. Then I unscrew the fitting on the clutch slave cylinder, unscrew the cap of the tank and put a clean cloth on its neck, for example, a handkerchief, create pressure with my mouth, that is, I simply blow into the tank. I blow several times to bleed the system and completely expel air from it. I can recommend another fairly simple pumping method, in which the liquid passes through the system by gravity, for which it is enough to unscrew the fitting on the working cylinder and control the level of liquid in the tank. When the air is completely out, we wrap the fitting.

Breakdown of the clutch master cylinder VAZ 2101 is a rare phenomenon. If problems arise, they are associated with damage to the anther or the use of low-quality fluid. If the mechanism malfunctions, you can restore the working capacity on your own. To carry out repair work, you need to prepare the necessary tools and read the step-by-step instructions, which will eliminate possible errors.

When should the clutch cylinder be replaced?

Ford Focus 2 clutch cylinder replacement is usually required when it is excessively worn. In this case, there is a leak of the working fluid. When examining the GCC, cracks, breakage of fittings, and mechanical damage to the body are found.

The first sign of a leak is brake fluid entering the passenger compartment. Its traces appear on the engine shield. Depressurization of the GCC leads to a decrease in the liquid level in the tank.

It is also necessary to replace the master cylinder in case of abnormal operation of the clutch. When the GCC fails, the driver has to press the pedal several times. There is airing of the hydraulic drive. Separation of the engine and transmission is not complete. Transfers are switched with effort and shock loadings. The efficiency of the brakes is reduced.

There are repair kits for sale. It is worth using them when the rubber seals are worn or damaged. If there is serious damage, it makes no sense to repair the assembly - the GCC assembly needs to be replaced.

Popular brands:

Ford Focus