A winch is installed on off-road trucks (ZIL-157, KrAZ-214. Ural-375, etc.). with which to overcome difficult road sections. evacuate stuck cars, lift and tighten loads.

ZIL winch

The winch is a drum on which the cable is wound. The drum is mounted on a shaft with a worm wheel engaged with a worm. The worm pair is located in the crankcase and is driven from the power take-off using a cardan drive. The power take-off usually has two working gears for pulling the load and one for unwinding the cable.

Most winches are equipped with an automatic band brake. With a sudden rotation of the winch drum under load in the opposite direction, i.e. when the car's clutch is disengaged, the brake band tightens and creates significant resistance to the rotation of the brake drum. The stop of the drum is facilitated by the self-braking action of the worm pair of the winch.

Winch disassembled

Winches of GAZ-66 vehicles develop a pulling force of 3500 kg, ZIL-4500-5000 kg, Ural-375-7000 kg, KrAZ-214B-8000 kg. The working length of the winch cable is 55-65 m.

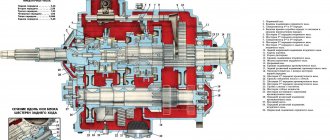

Power take-off

Installed on the gearbox, on the right side there is a hatch for installation. KOM with reverse, twists in both directions. The PTO consists of a gearbox housing, a gear block, a main shaft, a gear wheel axle, an engagement fork, 2 ball bearings, a flange. The PTO gear rotates from the rear speed of the gearbox. When installing the PTO, the shafts should rotate freely without biting the gears, turning by hand. The shaft is regulated by a set of paper gaskets under the bearing cover. The maintenance of the PTO box is the same as that of the gearbox.

power take-off zil

Block (polyplast) winches

Each car with a winch is equipped with a polyplast block. With this block, you can double the power of the winch, as it divides the effort in half. The winch cable during vehicle operation must always be tightly wound on the drum.

The winch is engaged in the same way as the gearbox. Squeeze out the clutch and turn on the PTO in the right direction and release the clutch. In some cases, it is possible to unwind the cable while the vehicle is moving.

polyplast block

Important when operating the winch

- Do not pull the cable to the very end, the remaining cable should be 4 turns of the drum. The working length of the cable is 65 m and the total length is 70 m.

- The oil temperature in the crankcase should not exceed 130 degrees.

- rope tension should not exceed 45kN. In other cases, use a pulley block.

- Turn on the PTO transfer case and pull the cable into tension with your hands.

zil winch diagram

Prohibited when using

- It is forbidden to turn on the reverse gear when the winch is in operation.

- When the winch is heavily loaded, gears cannot be engaged.

- It is forbidden to tow another vehicle with a winch.

- When the winch is in operation, it is forbidden to be near the cable and do not align the cable in the winch drum.

- If the winch overheats in the gears of the gearbox, it is necessary to stop the work and find out the cause of overheating.

worm gear

Winch Maintenance

A timely inspection of all parts is carried out, the bearing bolts are drawn, the oil is changed, the seals are checked, and the gear engagement is adjusted.

It is necessary to periodically lubricate the swivel joints of the cardan shaft and the winch drum shaft.

When a gap appears in the worm pair, the bearings are adjusted or the mechanism is changed.

The tapered worm bearings are adjusted by paper shims under the cover.

The adjustment of the engagement of the contact patch is determined by applying paint to the teeth of the engagement. The gearbox will heat up if the contact patch is not properly engaged.

WATCH THE VIDEO

Winch

Military Encyclopedia - historical and archival military-patriotic portal

home☆soviet military encyclopedia☆military equipment☆military science☆military review☆arms history☆forum

military equipment ☆ articles on the BAT device ☆

The winch is used for self-pulling the car, helping other stuck equipment, and can also be used to lift and lower loads.

The KamAZ-4310 car has a drum-type winch with a worm gear and a belt brake, the maximum traction force when the cable is issued back is 50 kN, when the cable is issued forward 35 kN, the working length of the cable when issuing back is 86 m, when issuing forward 79 m. The winch is installed in the rear of the vehicle frame on two crossbars and two brackets and consists of a worm gear, a drum with a cable, an automatic brake and a cable layer. The winch is driven by three cardan shafts from the power take-off mounted on the transfer case (see fig. 112). Power take-off control is electro-pneumatic. On the. a shearable safety bolt is installed on the rear propeller shaft to protect parts from overloads.

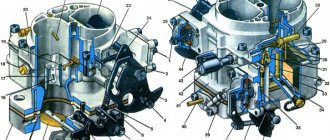

Rice. 183. Reducer winch car KAMAZ-4310 : 1 - splined bushing; 2 - glass; 3 - drum shaft; 4 - worm wheel; 5, 12 - bearing caps; b - brake tape; 7 - safety valve; 8 - bearings; 9 - crankcase; 10 - crankcase cover; 11 - worm; 13 - brake drum; 14 - reflector; 15 - spring; 16 - clutch; 17 - fork; 18 - plug stem; 19 - shims.

The winch gearbox serves to increase the torque on the drum; worm gear with a gear ratio of 31. It consists of a crankcase 9 (Fig. 183) with a cover 10, a worm 11 with tapered bearings, a worm wheel 4, a clutch 16 with a fork 17 and a rod 18. The worm is globoidal, single-thread, made integral with the shaft , which is installed in the crankcase on two tapered bearings, the bottom of the cover of which is lined with shims. The worm wheel is freely located on the drum shaft and can be connected to the gear rim of the shaft using the clutch 16. The clutch is moved by a lever located at the winch on the left side member of the frame.

The traction drum is used to create traction and lay the cable. The drum shaft is mounted on bushings in the gearbox housing and the winch traverse. The shaft is connected to the drum through a splined bushing 1. The cable is attached to the drum flange with a bracket. A hook is attached to the free end of the rope with a wedge. The wedge fastening of the hook makes it easy to remove it from the cable when changing the direction of the issuance of the cable.

An automatic brake prevents the load from falling in the event of a break in the connection between the engine and the winch gearbox. The brake is a drum band brake, located in the inner cavity of the cover 5. The brake drum is fixed on the worm shaft with a key. The brake band has an internal friction lining. One end of the band 6 is rigidly fixed in the wall of the bearing cover, the other is movably in the opening of the cover by means of a spring 15. When the drum rotates together with the worm to receive the cable, the friction force on the tape is directed in such a way that it cannot tighten the tape on the drum due to the deformation of the spring; when the direction of rotation changes under the action of friction forces, the tape self-tightens, causing the worm to brake.

At a low speed of the brake drum, the braking force is insignificant and does not prevent the cable from unwinding. When the drum rotates quickly (for example, in the event of a breakage of the safety bolt), the brake action becomes significant and serves as an addition to the self-braking action of the worm pair. The tension of the brake band is regulated by the nut that secures its fixed end. The brake must be adjusted so that the brake drum does not become excessively hot when the cable is unwound.

The cable guide is used to correctly lay the cable on the drum. The main part of the cable laying machine is the lead screw driven by a chain drive from the drum shaft. The screw has right and left threads, the ends of which coincide. The body of the cable layer is moved along the screw, two rollers are installed on its axes, between which the cable passes. When the drum shaft rotates, the lead screw rotates synchronously with it, while the body of the cable laying machine, together with the rollers, moves along the screw, ensuring the cable is laid on the drum.

In the transport position, the end of the cable clings to the towing hook attached to the front end of the left side member of the frame. On the right side member there are support rollers and a wedge for attaching the cable when pulling the car back using the block

Guide rollers are placed in the front and rear of the frame. To turn on the winch, depress the clutch pedal to failure, set the transfer case to neutral, turn on the power take-off and release the clutch pedal. The forced release of the cable is ensured by engaging the reverse gear in the transmission box; to wind the cable, turn on the first gear.

On the Ural-4320 vehicle, a winch with a maximum traction force of 70 kN and a working cable length of 65 m. It is installed on a special cross member and two brackets at the rear of the frame; the issuance of the cable is made back.

The winch drive is carried out through the power take-off; mounted on the transfer case and cardan transmission, consisting of three cardan shafts and two intermediate supports. The power take-off is switched on by a lever located in the cab. The winch includes a worm gear, a traction drum, a drum clutch, an automatic brake and a cable layer. The drum clutch is mixed with a fork with a lever, which is located at the rear end of the right side member of the frame. The winch reverse is provided by engaging the reverse gear and the first gear in the gearbox.

A winch is installed on the ZIL-131 car with a pulling force on a cable of 45 kN (maximum force 50 kN) and a working cable length of 65 m. The winch is located in the front of the car and is bolted to the front buffer and the front cross member of the frame (Fig. 184).

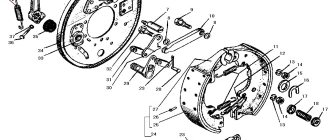

Fig.184. ZIL-131 car winch : 1 - barabaia engagement clutch; 2 - drum engagement fork; 3 - safety bracket; 4- guide roller; 3 - cable; 6 - reducer; 7 - traction drum; 8 - cardan shaft; 9 - power take-off control lever; 10 - power take-off; 11 - drum brake shoe.

The drum is switched on by a cam clutch 1, moved by means of a fork 2. The switching fork is equipped with a brake shoe 11, which abuts against the drum flange, slows down its rotation and prevents the cable from self-unwinding when unwinding it manually.

A distinctive feature of this winch is the absence of a cable layer. The cable is moved along the guide roller 4. In the transport position, the cable is fixed to the right front tow hook.

The winch drive consists of a power take-off 10 and a driveline. The power take-off is reversible, with two gears, the gear ratio for winding the cable is 1.0 for unwinding 0.76. The power take-off is mounted on the flange of the right hatch of the transmission box and is controlled by lever 9. The cardan transmission from the power take-off to the winch gearbox consists of two cardan shafts with three hinges and an intermediate support.

Rules for using the winch. When the vehicle is moving, the winch cable must be tightly wound on the drum, and the drum must be turned on. The drum is turned off only when the cable is manually unwound. Forced unwinding of the cable is allowed, while manually selecting the slack in the cable.

There must be at least four turns of cable on the drum before starting to pull up. The angle of deviation of the cable from the axis of the car when pulling up should not exceed 15 °. When pulling, the engine speed should be increased smoothly, a sharp increase in frequency does not increase traction on the cable, but can lead to shearing of the safety bolt

For self-pulling out of the car, it is necessary to hook the cable to an object or drive a stake into the ground with an inclination in the direction opposite to the movement of the car. Then turn on the lowest gear in the transfer case and the first gear in the gearbox (on the Ural-4320 car - reverse gear).

To increase the traction force, it is necessary to use a block with a chain that is attached to the car. In this case, the block is strengthened by a foreign object, the cable is passed through the roller of the block and hooked to the hook of the car with its end (on the KamAZ-4310 car, when pulling back, the cable is attached with a wedge to the bracket on the right side member of the frame).

It is forbidden to use the winch cable to tow another vehicle, to be near the tensioned cable or under the load being moved, to change gears when pulling loads, to pull the cable across the road. When the winch is running for a long time, it is necessary to take breaks to cool the gearbox.

Maintenance of winches consists in checking and tightening all fasteners, lubricating the drum shaft bushings, changing the oil in gearboxes, adjusting bearings and gearing of worm gears.

3.9 liters are filled into the winch gearbox crankcase of a KamAZ-4310 car, 7.5 liters of Ural-4320 car, 2.4 liters of TSp-15K or TAP-15V brand oil.

Tags: zil 131 ☆ kamaz 4310 ☆ ural 4320 ☆ car device ☆

| Vehicle plumage < Prev. | Track. > Tire pressure control system |

Buy an electronic signature for a legal entity inexpensively in Moscow

issuance of an electronic digital signature

- Contacts:

- +7

- around the clock

- seven days a week

© Military Encyclopedia. Map of site.