26.09.2011 00:30

Suburban LPG bus NEFAZ-5299-11-31 (4×2) is designed to carry passengers on suburban routes.

The body is made of all-metal, load-bearing, wagon layout with two double doors with a pneumatic drive. Engine location - rear. Ventilation - natural - supply and exhaust through the roof hatches and vents of the side windows.

Heating is carried out from an autonomous gas heater.

The total volume of the fuel system cylinders is 984 liters. and holds 197 m 3 of compressed natural gas (CNG) at a pressure of 200 atm.

Source

KamAZ on methane: the principle of operation of the engine, fuel consumption per 100 km, reviews

Natural gas used as motor fuel is highly resistant to detonation and reduces harmful emissions. Spark-ignition and compression-ignition engines are capable of running on gaseous fuels. The development of a methane-powered KamAZ truck began in 1984, and several small series were produced. With the collapse of the USSR, the assembly of such equipment ceased. In 2015, new versions of trucks equipped with gas-diesel engines appeared in the production program of the plant.

KamAZ on gas: reviews of owners of trucks with a gas engine

Natural gas methane, as an alternative motor fuel, attracts with its reserves in Russia. In addition, it has a high detonation resistance, low toxicity. Soft operation of the engine, increases its service life before overhaul by one and a half, two times, and reduces oil consumption by half.

Gazprom will expand the domestic market of the country thanks to natural gas motor fuel. Agreements have already been signed with a large domestic company, the KAMAZ automobile corporation.

Among the popular world companies that produce heavy trucks, this corporation occupies the 16th place. It includes more than 150 organizations located in Russia and other CIS countries. The production of trucks covers the entire technological cycle of the group of organizations.

It all starts with the design, modeling, automotive assembly and installation of automotive components, and ends with the implementation of manufactured machines and services.

In addition, based on a course to increase the need for the use of CNG as the main fuel for motors, the company is the main company in the supply of specialized vehicles. Today it is impossible to imagine the sphere of the gas engine products market without OJSC KAMAZ.

How does it work

Due to the increased octane number of gas fuel, the use of a standard motor is unacceptable. To operate on pure methane, a new engine is required, which increases the cost of the car. Therefore, the gas KamAZ is equipped with a specially modified standard power plant. The motors have a block head with a different design, which reduces the compression ratio to 12. The piston group and valves are subject to changes, since the combustion temperature of the gas mixture is higher.

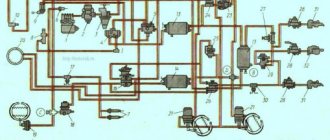

The principle of operation of the engine is based on the ignition of a mixture of gas and air by a spark from a spark plug, which is installed instead of a fuel injection nozzle. The gas supply is carried out by a multi-point injection system into the intake manifold. The injectors are located close to the cylinder intake ports, which ensures a homogeneous mixture and reduces exhaust emissions. Fuel supply and ignition are controlled by an electronic controller.

An alternative option is based on mixing liquid diesel fuel with gas in the required proportion.

Starting the power plant is possible only on diesel fuel. Then the gas is supplied through a special reducer that lowers the pressure. After that, the gas entered the mixer, which formed the working mixture. The design of the assembly had a speed controller, and a limiter was also installed for the volume of the supplied combustible mixture.

The working mixture was compressed in the cylinder. A small dose of diesel fuel is used for ignition. The moment of dose delivery is calculated in such a way that it will ignite before the volume of gas. After the flash of diesel fuel, the combustion of a mixture of methane and air begins. Such a scheme of a gas engine made it possible to work on liquid and gaseous fuels. But the design did not receive development.

Early and experimental versions of the machines were equipped with a balloon installation located behind the cab or on the frame. Then there was a scheme for mounting 8 cylinders parallel to the frame spars. The containers are installed symmetrically to the longitudinal axis of the vehicle on special protective cradles. There is a combined scheme: some of the tanks are mounted behind the cab, and some are under the loading platform or dump body. All cylinders are interconnected by pipelines with safety valves and valves.

Specifications

The main characteristics of the engine of the KamAZ-840 family:

- cylinder diameter - 120 mm;

- piston stroke - 130 mm;

- working volume - 11760 cm³;

- power - 300 hp at 1900 rpm;

- torque - 1225 N / m at 1200-1400 rpm;

- compression ratio - 12;

- fuel consumption - 25-30 m³ of gas per 100 kilometers;

- toxicity standard - Euro-4.

Some modifications of the KamAZ truck are equipped with imported diesel engines adapted to run on methane. Motors meet Euro-5 standards. The plant produces trial models of cars with a Mercedes Benz engine capable of running on both pure diesel fuel and a mixture of diesel fuel and methane.

The gas supply is located in cylinders placed behind the cab (with a capacity of 80 liters) and on the frame (volume 100 liters). The standard equipment provides for the installation of 9 small and 7 large tanks with a capacity of 1420 liters. The total supply of methane compressed to a pressure of 200 atm is 284 m³.

Owner reviews and installation price

The cost of a truck tractor equipped with gas equipment starts from 3.4 million rubles. The price of converting a diesel car into a gas-balloon version is 0.5-0.7 million rubles. For this amount, the engine is rebuilt, cylinders and lines are installed on the frame. The owner is issued a certificate allowing to operate the truck. Handicraft alteration of engines is prohibited.

Alexander, 38 years old, Krasnodar Territory.

A dump truck is in operation, equipped with a gas-cylinder installation at the factory. For six months of operation had to replace 1 of the candles. The engine torque is enough to drive a fully loaded car. The gas supply is enough for an average of 400 km. The downside is the duration of refueling (30-40 minutes), as well as the location of the gas reducer, which is filled with water. There is a problem of jamming valves on cylinders.

Oleg, 43 years old, Yekaterinburg.

The organization purchased several truck tractors with a motor converted to gas fuel. Cars are used to transport goods over distances of 300-500 km. Of the positive aspects - a stable thermal regime during engine operation, there is no smell of diesel fuel and burning. But the first service at the dealer costs 55 thousand rubles, the second is cheaper - 13-25 thousand rubles. The cost depends on whether the spark plugs have been changed or not. An additional disadvantage is the increased oil consumption of the engine.

Pros and cons of Kamaz on methane

The main advantages of KAMAZ on methane:

- low fuel consumption;

- silent operation of the engine;

- environmentally friendly type of fuel;

- reducing carbon dioxide emissions into the environment;

- on gas engine equipment, there are less costs for spare parts;

- methane is used as fuel, it is the safest type of fuel.

The main disadvantages of Kamaz on methane:

- possible malfunctions in the cold season;

- unsafe equipment in emergency situations.

Rules for the operation of vehicles with LPG

Guide to launching HBO on Kamaz:

- turn on the ignition, the engine will first start running on gasoline;

- the red light flashes on the cng switch, it means the car is running on gasoline;

- in cold weather, the engine needs to be warmed up to 35 degrees, if this is not done, then the gas equipment may fail;

- switch the engine to gas equipment.

- Then, when you have problems with the operation of gas equipment, you should not try to fix it yourself. You must immediately contact the service center.

- You can not operate the car when the gas in the tank is less than 10%.

- The air filter needs to be replaced every 5000 kilometers.

- Accumulated condensate must be regularly drained into HBO. This must be done every 3000 kilometers.

- If there is a malfunction in the operation of the equipment, then you need to switch to a gasoline run and contact the service station.

- The vehicle must not be used when there is no fuel in the petrol tank.

Propane cars work the same way.

Requirements for gaseous fuels

The main requirements that LNG must meet:

- the gas must be highly miscible with air in order to produce a combustible mixture;

- the mixture should have a high calorie level;

- when compressed gas is burned in engines, there should be no detonation;

- minimum content of impurities in the gas;

- the ability to store their properties for a long time;

- low cost.

Major faults and repairs

Carrying out repair and maintenance of Kamaz on LPG has a number of features. If during the repair there will be a thermal effect on the car, for example, welding, you must perform the following steps:

- release all gas from the cylinders;

- transfer all remaining gas with the engine running;

- purge the cylinders with nitrogen;

- tightly close all valves;

- as soon as the repair is completed, you need to check the gas equipment for damage.

Possible malfunctions in gas equipment are presented below.

Car won't start:

- tightly close the HBO valve;

- stop the gas supply;

- check the engine cooling system;

- check the reducer valve.

If you smell gas, you need to check the connections inside the gas equipment.

Gasoline fuel consumption increases significantly after switching from LPG, then it is necessary to check the tightness of the solenoid valve.

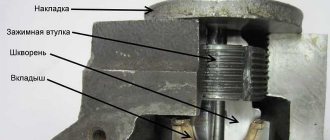

Engine performance deteriorates with increasing mileage. This may be due to worn parts.

A warm engine does not start immediately:

- displacement of the adjusting screw;

- pressure drops inside the cylinders;

- cylinders pass gas.

Excessive gas flow may be due to a leak in the fuel hose or a clogged air filter in the cylinders.

The consequences of installing gas for a car

Methane vehicles have a number of operational implications. In particular, we are talking about characteristic engine breakdowns, general wear and tear, loss of power, etc.

Often, car owners note that the use of this equipment, which makes it possible for the car to run on methane, warps the block head, since it simply heats up more on gas and has to be polished over time. This failure, noticed at the wrong time, threatens to overhaul the engine.

The easiest way to notice a malfunction is due to some instability of the idle operation of the machine after a short run.

Also an important aspect is the burnout of the valves, which can result in a good penny for the owner.

Operational consequences due to the processes occurring inside the system cling to valves, cylinders and pistons! This quite often results in an expensive and very technologically complex pleasure. As for the general wear and tear of the car, it is difficult to comment on this factor.

We can only say unequivocally that over time, under the influence of many factors, there is a loss of machine power, which cannot but affect the general technical condition of the transport.

In order to develop the gas motor fuel market, it is necessary to act in a comprehensive manner. Some should create high-quality equipment, others should provide its services, and the third should provide the country with gas filling infrastructure.

Soon, state programs will take part in creating a decent service for this type of transport.

This year, it is planned to mount block filling modules at ready-made filling stations.

Summing up, we can note that methane-based equipment is environmentally friendly and affordable. Many modern cars equipped with these installations make the use of the car more economical and functional. Gas emissions become very clean and harmless, and this is already a huge plus for the environment and not only.

It is assumed that in the near future the technique will work exclusively on methane.

In the meantime, read the article about the new Kamaz models.

Kamaz on methane

Kamaz 5490 is a gas-diesel vehicle. This methane-powered model has become very popular due to its comfort and low fuel consumption. In addition, Kamaz is equipped with an engine from Mercedes.

Kamaz 65115 also runs on natural gas. This is an all-wheel drive construction dump truck. It has 2 leading rear axles, thanks to which it can carry cargo weighing up to 15 tons.

Thus, Kamaz on methane is now gaining great popularity. New models are also equipped with gas equipment, as this allows you to reduce fuel costs by almost 2 times.

The main characteristics of gas-balloon KAMAZ

The motor here is represented by model 820.60. Vehicle parameters: 7300X2500X2845 mm. The model is equipped with an interaxle differential lock and an interwheel lock, spring lighting is mounted.

Consumption of this KAMAZ model on methane: 34 l/100 km. (as in 65205) The price of the model is 2,857,220 rubles.

All information about Kamaz can be found on our website. This is an overview of the dimensions of Kamaz vehicles.

You will learn about the capacity of Kamaz in this article ...

It will also be interesting to get acquainted with the range of prices for Kamaz.

City Bus 5299-30 on methane gas - characteristics and fuel consumption

Transportation of citizens and guests of the country along narrow city roads is now possible on gas-balloon semi-low-floor transport.

All-metal body, double doors with pneumatic drive. Rear engine. Ventilation - classical, through the opening of hatches and molds. 984 l. is the total volume of the fuel system cylinders, it can hold 197 m3 of CNG at a force of 200 atm. Semi-low-floor design increases the convenience of boarding and disembarking in a vehicle.

The power unit uses a VOITH D845.3E gearbox. The KAMAZ gas engine is represented by model 820.61. Characteristics of the model 5299-30 KAMAZ on methane. Overall dimensions: 11875X 2050X 3400 mm. The price of the model is 7,660,000 rubles.

For transportation of citizens and guests of the country along routes that lead outside the city, transport of the 2nd class 5299-0000011-31, model 5299-011 is suitable. It offers seating areas, as well as areas that are most suitable for passengers who want to stand up.

The bus consists of a frame all-metal, one-piece body. The advantage is its resistance to maintaining the desired air temperature and the rear engine. Ventilation - natural, through open windows and hatches.

Heating system: built-in autonomous and emergency. The first one is powered by a gas heater, the other one works in addition to the main one. These are the main features of this Kamaz model on methane. The price of the model is 8,708,300 rubles.