How to break in a walk-behind tractor?

Walk-behind tractors are run in immediately after purchase or after overhaul. Before starting the run-in, you need to do the following:

- tighten bolts and other fasteners;

- check the technical condition of the steering and brakes;

- adjust the steering wheel to a comfortable position;

- check the condition of bearings and seals;

- lubricate clean and dry parts, pour oil into the crankcase (lubricants and fuel should be used

- recommended by the manufacturer).

The process of running in any walk-behind tractor is, first of all, “grinding” of parts and assemblies of all systems of the unit. In this regard, running-in is carried out at low loads for about the first 20 hours of operation of the equipment. After the break-in is completed, all systems and components of the walk-behind tractor are also re-inspected, and they are lubricated.

Why do you need a wrap

Engine break-in is an important procedure. As mentioned above, it allows you to extend the service life. It is necessary to do it not only when buying a new element, but also after a major overhaul of the old one. Before the procedure, check the fastening of all bolts. They must be fixed, and the walk-behind tractor itself is filled with gasoline, grease and coolant.

During operation, it is necessary to check the operation of the brake and steering system more than once. The steering wheel itself must be in the normal position - this is important. After running-in, the element is inspected and maintenance is carried out. This must be done every 2 thousand hours of operation. All parts must be wiped with diesel oil. The condition of bearings and seals is constantly checked, if they are worn out, they are replaced. The fork and control spring must be reliable. Otherwise, problems may arise.

All drives and axles must be in perfect condition. If they are worn out, they are replaced immediately. Maintenance is carried out in accordance with the attached instruction manual.

Running in a cultivator is one of the most important activities. But before that, you need to prepare. Each part should be lubricated with grease, according to the manual. Cleanliness must be observed when filling oil and lubricant.

Transmission oil must be replaced only after the walk-behind tractor has completely stopped. However, it must be drained hot. Then diesel oil is poured in and the switch box is washed. The lubricant must be used according to certain requirements:

- for a walk-behind tractor engine, it is necessary to use transmission oil, preferably TAD-17;

- semi-synthetics are suitable as a diesel lubricant, it is recommended to use 8AE-30;

- along with this, synthetic lime grease is used.

All information is provided in the user manual. The further period of operation depends on the correctness of the actions.

General rules for running motoblocks

For a successful break-in, do not forget about these rules:

- Before each start, check the oil level in the engine and do not forget to fill in the required quality fuel.

- Control engine speed. Ideally, it should work alternately in all gears at medium speeds.

- In light load mode, carry out manipulations with attachments (cultivation, plowing, transporting goods).

- Upon completion of the break-in, change the oil in the motor and transmission units. The oil is changed only after the walk-behind tractor is turned off. Gear oil must be drained immediately before it cools down.

- In no case do not run the engine of the walk-behind tractor idling at high speeds - this can damage it.

How to run in a walk-behind tractor

Running in a diesel or gasoline walk-behind tractor is the grinding of all elements and parts in your system or unit. The process is carried out in the mode of low loads, on average, the first 20 hours of operation of the machine.

There are four things to keep in mind in order to get it right:

- The oil level in the engine is checked before starting. In case of shortage, top up above the minimum mark on the dipstick.

- Before starting work, the tank is filled with fuel of the grade and quality required by the operation manual.

- The control is carried out so that the motor runs for some time at medium speeds. The engine must be running in every gear from first to last.

- During the running-in process, a new walk-behind tractor is tested in functional modes. The cultivation and plowing of the soil is carried out, as well as the transportation of goods in compliance with the permissible loads specified by the manufacturer.

Important to remember! At the end of the break-in, the oil is changed in the engine and in the transmission units of the machine.

You should also know: when the walk-behind tractor is in place, it is forbidden to accelerate the engine to full speed.

Running in individual models of walk-behind tractors

Some models of walk-behind tractors have their own characteristics when running. Let's consider them in more detail on the examples of several well-known brands.

Motoblocks Shtenli

Initially, you should check the condition and degree of fastening of all parts and connecting nodes, check the oil and fuel levels. Check the smoothness of the clutch and gas, how easy it is to change gears.

When starting for the first time, let the engine run for half an hour at idle. During the first operation with attachments, it is allowed to perform such work as plowing, cultivating, hilling, mowing grass, etc. The load during the transportation of goods should be no more than half of the regulated mass.

A typical run-in lasts about 15 hours. After that, it is necessary to carry out a complete technical inspection of the unit.

Description

Perm walk-behind tractor Bright 68 has a large cutting width of up to 120 cm. This attachment comes with the machine. Its blades are made of hardened metal and are capable of processing even the toughest soils.

Motoblock Bright BR-68 (wide wheels)

The maximum load capacity of the Bright 68 walk-behind tractor is 500 kg.

Thanks to the universal hitch, Brait BR-68 can work with attachments from third-party manufacturers: Cascade and Neva.

The manufacturer paid special attention to the quality of the motor. It has a Brait 170F engine, which is an analogue of the Honda GX-210. It is equipped with a sleeved cylinder and is able to withstand heavy loads for a long period of time.

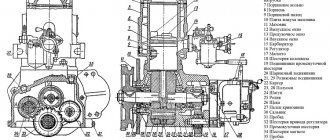

Brait 170F engine

Engine crankcase BRAIT 170F

Buyers are offered two modifications of the Brait BR-68 walk-behind tractors, depending on the installed wheels.

Brait 68 (with 4×10 wheels)

This standard walk-behind tractor is designed for processing a small plot of land and is able to provide performance on soft and medium soils.

Motoblock Brait 68 (with wheels 4 × 10)

Specifications

| Weight, kg: | 105 |

| HP power: | 7.0 |

| Engine's type: | 4-stroke, single-cylinder engine |

| Fuel tank capacity l: | 3,6 |

| Displacement (cm3): | 208 |

| starter: | manual |

| Depth of processing, mm: | 150-300 |

| Processing width, mm: | 800-1200 |

| Output shaft: | 20(keyway) |

| Oil capacity, l: | 0,6 |

| Wheel size: | 4×10 |

| Milling shaft: | hexagon S23 |

| Number of gears: | 2 forward, 1 back |

| Reducer oil volume, l: | 1,3 |

Brait 68 (with 19-7×8 wheels)

Perm motoblocks with such wheels are capable of plowing and milling virgin lands, as well as transporting goods on viscous soils. They are equipped with wide tires with aggressive tread, providing reliable grip on the surface.

Due to the increased width of the wheels, the weight of the Brait BR-68 walk-behind tractor has increased by 4 kg.

Motoblock Brait 68 (with wheels 19-7×8)

Specifications

| Weight, kg: | 108 |

| HP power: | 7.0 |

| Engine's type: | 4-stroke single-cylinder |

| Fuel tank capacity l: | 3,6 |

| Displacement (cm3): | 208 |

| Engine brand: | BR-170F |

| starter: | manual |

| Depth of processing, mm: | 150-300 |

| Processing width, mm: | 800-1200 |

| Output shaft: | 20(keyway) |

| Oil capacity, l: | 0,6 |

| PTO: | No |

| Wheel size: | 19x7x8 |

| Milling shaft: | hexagon S23 |

| Number of gears: | 2 forward, 1 back |

| Reducer oil volume, l: | 1,3 |

Motoblocks Neva with Subaru engine

This walk-behind tractor is run in for 20 hours (like other Neva models with different engines). During this period, the load on the walk-behind tractor must not be exceeded. Cultivation should be done no more than 10 cm, and loads weighing no more than 200 kg should be transported.

Motoblocks Centaur

The running-in of the Centaur air-cooled engine should be carried out according to a clear algorithm:

- the first three hours the engine should work at a third of its capabilities;

- drain the oil from the engine and transmission units, replace it with a new one;

- then for 4 hours let the walk-behind tractor work at 2/3 of the engine capacity.

Also, do not forget about the load limits after the break-in is over. Perform regular maintenance and repairs.

Motoblocks Oka with Lifan engine

This model runs in about 30 hours, performing simple work with minimal loads. When running with attachments, remember the following rules:

- on difficult soils (for example, on clay), you should not work for more than 2 hours;

- throttle valve should be 2/3 open;

- plowing should be carried out to a depth of 10 cm in one pass.

Operation and maintenance

The operation and maintenance of the Shtenli 1900 pro series walk-behind tractor is carried out in accordance with the following rules:

- running-in from 8 to 10 hours, engine load - 2/3 of the power;

- engine oil - SAE5W-30 (synthetic in winter, semi-synthetic in summer), transmission oil - 80W-90 (or equivalent in viscosity);

- oil change - after break-in, then every 50 hours;

- during storage, the walk-behind tractor is left with an empty gas tank and oil sump;

- store the device at a positive temperature;

- once a year, replace or clean the spark plug, oil and gasoline filters.