Works performed TDT-55

Onezhets TDT-55 replaced the post-Soviet pioneer among skidders - TDT-40 and was produced for 37 years. The purpose of this equipment is the selection and transportation of fallen trees with units from logging platforms.

Skidder TDT-55 rightly won the trust and authority of loggers, because. its engineers effectively addressed the issue of high efficiency, combined with a simple design, durability and maintainability in difficult field conditions.

Design features of TDT-55

At its core, the skidder TDT-55 contains a strong welded box-shaped frame. In order to preserve the components of the transmission and engine, specialized hinge sheets are attached to the beams and side members of the frame using bolts. During technological maintenance, it is required to periodically clear the frame from clogging and wood fragments. The driver's cabin is asymmetrically placed on the frame. The driver also plays the role of an operator of attachments.

The carefully soundproofed cabin has a large glass area at its disposal, which allows you to observe the working area around the skidder. For the convenience of the operator, there is a fan and a strong heater. Management is meaningfully facilitated, since the presented equipment is specialized for performing work on hard-to-reach forest areas. For the same reason, as little electrical equipment as possible is conceived in the device. The regulation of the process is carried out using two levers, with the help of which turns are made and the unit is braked. Pedals are used: clutch start and fuel supply. Directly next to the cab is a diesel engine, covered with a metal hood.

Diesel engines SMD-14N and SMD-18N-01 are used as a power plant. To start, there is a P-10UD unit with a personal gearbox.

TDT-55A

TDT-55A skidder is a modification of the TDT-55 tractor with more advanced functionality.

The TDT-55A machine is equipped with a 4-cylinder compressorless diesel engine SMT-14 with a vortex-chamber mixture or SMD-18N-01 with a P-10UD launcher and a gearbox. Motor power - 75-80 and 95 hp. With. respectively. The speed of rotation of the crankshaft is 1800 rpm. Fuel consumption is 218 g/kW*h.

The late TDT-55A-05 model is equipped with the D-245L engine - a 4-stroke turbocharged diesel engine with a power of 105 hp. With.

The power plants and transmission are located in such a way that the frame pan protects the components from stones, stumps and small shrubs, and the cab hood protects the fuel tank and hydraulic tank from external mechanical damage.

The overall dimensions of the skidder 55A are 5800x2357x2560 mm.

The operational weight of the TDT-55A tractor is 9600 kg, the structural weight is 9200 kg.

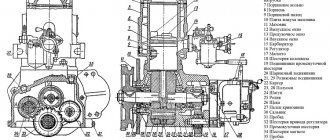

Engine TDT 55

The heart of the TDT-55 tractor is the SMD-14B engine, which was designed and subsequently manufactured at a plant located in Kharkov.

Main technical indicators:

- number of cylinders: 4 pcs.;

- maximum power: 62 hp;

- rated speed: 1500 rpm;

- specific fuel consumption: 160 g/l s. h.

After the modernization, the tractor was equipped with a more powerful engine - SMD-18N, which has the following performance characteristics:

- number of cylinders: 4 pcs.;

- maximum power: 100 hp;

- rated speed: 1800 rpm;

- specific fuel consumption: 162 g/l s.h.

Subsequently, work was carried out aimed at increasing engine power to 120-130 hp. However, this decision was rather controversial, since the performance of the tractor, due to the peculiarities of its operating conditions, actually remained unchanged. At the same time, fuel consumption has increased significantly. D-245 engines were installed on the latest manufactured models of tractors.

Pros and cons of TDT-55

Users take into account the advantages when choosing a TDT-55 tractor for heavy forestry work:

- High maneuverability. This makes it easy to turn around on the tractor in a small area.

- An economical motor is used. The technical characteristics of the unit will be optimal.

- Increased ground clearance allows you to properly control the vehicle.

- The spring suspension is distinguished by the correct setting and precise balance. The move becomes soft, smooth.

- The low center of gravity and the stable base ensure optimal vehicle stability on steep slopes.

- The transmission and motor are protected. Stones, stumps, protruding branches in the forest become harmless for the technical components of the tractor.

- A special device for tensioning and damping is provided. It is mounted on the steering wheel. The device protects the caterpillar from excessive tension when overcoming obstacles.

- On board special chippers are installed. They protect the caterpillars from excessive risks and external factors. Fenders extend track life.

Such advantages of the tractor allow you to plan specific work in the forests.

Cons are also taken into account when choosing a tractor. The further use of TDT-55 depends on this. Minuses:

- Sometimes repairs become difficult. Sometimes it is necessary to dismantle the tractor to replace parts. For example, the gearbox is hard to remove. In case of minor breakdowns, repairs are carried out easily and quickly.

- Technical details are offered at high prices. Repairs will be costly.

- Sometimes there are clutch issues. It is important to eliminate them for proper operation on the tractor.

- SMD engines are characterized by insufficient reliability and low overhaul time.

Taking into account such shortcomings allows you to make the right decision regarding the purchase of TDT-55.

Transmission TDT 55

The gearbox is located on the flywheel of the engine and has the following gears:

- 5 steps: to move forward;

- 1 degree - to move back.

For the functioning of this unit, it must have a sufficient amount of lubricant. The filling volume in this case is 3.5 liters. A distinctive feature of the tractor gearbox lies in the special mechanism in its design that prevents gear shifting when the clutch is engaged or not fully engaged.

Winch TDT 55

One of the key parts of this type of equipment is a winch, since it carries out a whole list of various works. The winch is driven by a power take-off shaft.

There are two main types of winches (one-drum and two-drum), which are installed depending on the modification of the tractor. The winch is located at the rear wall of the tractor cab. The drive is carried out through a cylindrical bevel gearbox, control can be carried out directly from the tractor driver's cab.

The device of the tractor LHT-55

The frame of the tractor LHT-55 is a rigid welded box-type structure, on which all blocks and devices of the tractor are mounted. The diesel engine is mounted in the front of the frame on several supports (one front and two rear), rubber-metal shock absorbers are used for damping. The gearbox is connected to the engine flywheel housing. The following tractor components are mounted on the rear end of the frame:

- rear axle system with final drive;

- rotary mechanisms;

- brakes;

- onboard transmissions.

Between the diesel engine of the LHT-55 tractor and the gearbox is a clutch. Its shaft is attached to the input shaft of the gearbox with the help of a gear coupling. With its front end, the coupling shaft is recessed into the bearing, which is sealed with a frame gland.

The running gear of the tractor consists of the following elements:

- Suspension and track rollers;

- Guide wheels (together with tension and damping devices);

- Driving wheels;

- Caterpillars.

The suspension of the LHT-55 agricultural machine is made up of four identical carriages, which are fixed to the frame by hinged mechanisms by levers, and their lower heads are supported by springs mounted on the main load-bearing element of the frame along the entire structure, in special casings. The drive wheels are bolted to the side of the tractor frame and are seated in the grooves of the driven shaft of the transmission unit (final drive).

The tractor track looks like a closed band that surrounds the guide and drive wheels and road wheels. It consists of cast links, pivotally connected to each other by fingers.

The LHT-55 tractor is equipped with a single-seat closed cab, which is integral with the hood, which is fixed on the wings located on the front of the frame. The cab is semi-open, since this type of tractor is designed to work in a tropical climate.

The front control axle of the technical facility, the hydraulic booster, as well as the soft operator's seat to be adjusted, are located on the left frame opening, which simultaneously plays the role of the cab bottom.

The hood of the LHT-55 tractor is divided into two sections. Both open: the left one opens from inside the cab, the right one opens from the corresponding side of the tractor. Under the hood of the tractor are the following units of the unit:

- engine;

- fuel and oil tanks;

- hydraulic distributor;

- accumulator battery;

- starting engine tank;

- water and oil radiators;

- blinds.

Also, the tractor is equipped with a winch, which is located behind the cab on the frame, a pusher and a front lifting device. An intermediate gearbox is fixed on the cross link of the frame, through which the winch drive is implemented, from the power take-off shaft using two cardan shafts.

Transmission and systems TDT-55

Dry clutch with 2 discs contains hydraulic booster and front brake. The 5-speed non-synchronized gearbox is equipped with a gear connection stopper when the clutch pedal is not depressed. Cardan gears and rear axle equipped with band brakes. Winch drive transmission with power control shaft. The hydraulic system contains 2 separate circuits and one common tank. The main HS circuit is powered by the NSh-10 pump and guarantees the movement of the tractor. The working tools and the auxiliary mechanism are controlled by the 2nd circuit using the NSh-50 pump.

Lever-balance suspension of the undercarriage system uses spring suspension, wheel guides with shock-absorbing and tensioning mechanisms, drive tracks and wheels.

The fuel supply system of the TDT-55 tractor contains the main and spare systems. Home is used continuously. An additional one is connected in cases where it is necessary to add power if the main system has failed. But the power of the spare vehicle is only enough to return to the base at the very minimum speed.

Working tools TDT-55: bulldozer pusher, skidding shield, winch.

Main characteristics of TDT-55:

- working weight with devices - 9600 kg;

- length - 5,850 mm, width - 2,357 mm, height - 2,560 mm;

- track width - 440 mm;

- ground clearance - 555 mm;

- traction force - 3,000 kgf;

- maximum speed - 13 km / h;

- fuel tank capacity - 140 l.

Despite the heavy weight, the caterpillar ground pressure is within 0.45 MPa, helping the special equipment to operate on the ground with a slight bearing feature.

Device and technical characteristics

The basis of the TDT-55 caterpillar tractor is a rigid frame of a welded box-shaped structure. To protect the engine compartment and transmission, special folding plates are located in the lower part, attached by fasteners to the spars and crossbars.

The operator's cab is in an asymmetric position relative to the frame. It is made of waterproof and heat-insulating materials. Most of it is glazed, which allows you to increase the viewing angle during operation and control the working area.

Inside the driver's cab there is a convenient dashboard with measuring instruments, a soft seat, a powerful heater and a ventilation system.

The design provides for a minimum amount of electrics: 2 front and 2 rear lights for working in the dark.

The TDT-55 tractor was first equipped with 4-cylinder diesel units SMD-14BN and SMD-18N with and without turbocharging. To launch them, a P-10UD trigger mechanism with a gearbox was mounted.

Engine power reached 95 liters. With. Difficult-to-maintain SMD-18N motors with a short overhaul life were converted into SMD-14, while the cylinder-piston group, the high-pressure fuel pump were changed, and the turbine compressor was removed due to low-quality fuels and lubricants. Later, a powerful diesel 4-cylinder D-245 engine, designed for 122 hp, was installed on the unit. With. at 1200 rpm. Fuel consumption - 17 liters per 100 km.

The skidder transmission is a dry clutch with 2 discs, including a front brake and hydraulic booster to protect against rider fatigue.

Gearbox - not synchronized, 5 speeds forward and 1 reverse.

The hydraulic system consists of 2 separate circuits and a tank. One circuit is responsible for the movement of the skidder and is controlled by the NSh-10 pump, the second circuit serves the hinged mechanisms through the NSh-50 pump.

The fuel system is a constantly working main and backup.

Working bodies:

- bulldozer hitch;

- skidding shield;

- reversible winch.

For the TDT-55 tractor, the technical specifications are as follows:

- overall dimensions - 5850x2357x2560 mm;

- operating weight - 9.6 tons;

- ground clearance - 555 mm;

- track width - 440 mm;

- ground pressure - up to 0.45 MPa;

- movement speed - 13 km / h;

- traction force - 3000 kgf;

- fuel tank volume - 140 l.

Weight characteristics

Before purchasing a skidder, buyers have a question: how much does the tractor and its individual parts weigh?

The operating weight in the complete set is 9.6 tons.

Skidder track weight (one link) - 9.5 kg. 140 links - a complete set of tracks - 1526 kg.

Frame weight - about 1.5 tons (depending on modification).

The question about the weight of the shield (dump) is also popular - it may vary due to the overall dimensions, modifications of the tractor. The weight of the TDT 55 knife is 200-300 kg.

Complete sets and modifications of TDT-55

During the manufacture of this special equipment, engineers continuously improved it, and at the moment, with the help of excellent running, traction and mobile properties and the ability to change attachments, the operation of the tractor has expanded and covers not only the logging craft, but also other areas of economic production.

2 modifications of the TDT 55 tractor were created:

1. TDT-55A-05 - with a more powerful and progressive diesel engine D-245L, with a power of 100 hp. and developing a maximum speed of over 15 km / h.

2. LHT-55 - equipped with a dump steel platform, attachments, front and rear PTO. The model is intended for reforestation, cleaning clearings, cutting areas and other production sites.

Overview of modifications

The production of tracked tractors TDT-55 at the Onega enterprise continued until 2003, during which time several successful upgrades were made:

- TDT-55

- TDT-55A

- TDT-55-05

- LHT-55

- TB-1

Many of our readers are interested in how much a tracked skidder TDT-55 can cost now? We answer: depending on the year of manufacture, condition and configuration, this tractor can have a price of one to two and a half million rubles. Let's take a closer look at each modification.

TDT-55

The weight of this caterpillar tractor is 9.6 tons. The skidder is equipped with a diesel four-cylinder power plant of the SMD-14B brand, the rated power of which was 62 hp. With. Gearbox five-speed, 5 speeds forward and reverse.

Tractor TDT-55

The tractor is equipped with a PD-10U gasoline two-cylinder starter installed outside the cab and started both manually and from an electric starter. The liquid preheater ensured a quick start of the engine even in severe frost.

TDT-55A

Some time later, the manufacturer decided to add power to the car and replaced the SMD-14B engine with a more powerful SMD-18N-01 (100 hp) - this is how the next modification TDT-55A appeared. For easy starting, a P-10-UD starting engine with a gearbox was installed.

Tractor TDT-55A

LHT-55

This modification was put into mass production in 1969.

Tractor LHT-55

The tractor has undergone a number of changes and received the following additional equipment:

- PTO located at the rear of the tractor;

- rear type hitch;

- rigid platform made of steel with the function of a dump truck, hydraulically controlled.

Scope of TDT-55

The basic machine TDT-55 and its 2 modifications are used as working machines for a wide range of applications in various fields:

- logging operations when felling forests;

- packaging during logging operations;

- delimbing work;

- earthmoving, loading or road construction work associated with complex soil or terrain overgrown with vegetation.

Due to its unique properties, this tractor is very often used in geological exploration. The great popularity of TDT-55 is due to its ease of use, the ability to perform repairs in difficult conditions, and most importantly, the high performance of units and assemblies. Tractor parts are available and relatively inexpensive. Manufacturers have managed to achieve such durability of the structure through the use of the most reliable and high-strength materials and constant work to simplify the mechanisms.

Characteristics of the skidder TDT-55

| dimensions | ||

| Length | mm | 7 600 |

| Width | mm | 2 500 |

| Height | mm | 3 740 |

| Weight | ||

| kg | 9 600 | |

| Speed | ||

| km/h | 2,9-12,8 | |

| Engine | SMD-18 / D245-16 / SMD-14 | |

| Power | kW (hp) | 90 (120) |

| Specific fuel consumption | g/kWh (g/hp) | 238 (175) |

| Number of gears | ||

| Forward travel | 5 | |

| Reverse | 1 | |

| Ground clearance | ||

| mm | 555 | |

| Track width | ||

| mm | 420 | |

| The greatest of the average caterpillar pressures on the ground | ||

| kgf/cm2 | 0,45 | |

| Fuel tank capacity | ||

| l | 120 | |

Engine parameters

When selecting engines for installation on this unpretentious special equipment, the manufacturers proceeded from the fact that not to complicate the overall design and at the same time get the maximum possible effect from the propulsion system.

Initially, the choice was made in favor of the SMD-18N.01 diesel engine:

- four-stroke diesel internal combustion engine with direct injection and turbocharging, water cooling;

- cylinder diameter - 120 mm;

- engine capacity - 6.3 liters;

- injection pump of Czech production;

- power in l. With. - 100;

- nominal speed - 1 800;

- specific consumption of diesel fuel - 224 g/kWh;

- diesel weight on average - 800 kg.

In the TDT-55A and LHT-55 trim levels, the SMT-14 diesel engine was installed with the following technical characteristics:

- four-cylinder compressorless internal combustion engine with vortex-chamber mixture formation;

- power in l. With. - 75-80;

- nominal speed - 1 800;

- specific consumption of diesel fuel - 218 g / kWh.

We have prepared for you a review of the Tatra-815 dump truck, from which you can find out the prices for this equipment.

This article: https://spez-tech.com/tehnika/selhoz/traktoryi/mtz-892-harakteristiki-i-description-modeli.html will provide more information about the technical characteristics of the MTZ-892 tractor.

D-245L engines began to be installed on later versions of the TDT-55A-05:

- in-line four-stroke diesel engine with gas turbocharging;

- engine weight - 490 kg;

- power in l. With. - 105;

- maximum torque - 384 Nm;

- nominal speed - 1,400;

- cylinder with a diameter of 110 mm;

- working volume - 4.5 l;

- specific consumption of diesel fuel - 220 g / kWh.