Checking and adjusting the carburetor of the MB5040 LUCH walk-behind tractor

If during the check of the walk-behind tractor before the season a bad start is found, do not rush to start adjusting the carburetor. To correctly determine the cause of a poor start, remove the glow plug and inspect it. If the candle is damp, then the cause of poor starting is in the ignition system, since the mixture enters the engine cylinder, but does not ignite. If the spark plug is dry, inspect the carburetor and

first of all, its idle system, the air damper.

The initial adjustment of the carburetor is made at the factory during manufacture. The carburetor can be adjusted at an enterprise that produces walk-behind tractors and engines for them, with. check engine operation.

Adjustment of the carburetor at the consumer is mainly carried out at idle. The maximum mode is provided by adjustment at the manufacturer of the walk-behind tractor with a full throttle needle 9 (Fig. 12.2, carburetor from the condition of ensuring transient conditions, power, engine efficiency, and it is desirable to save this adjustment.

Adjust the clarburator in the following sequence:

- turn the screw of the main jet 1 and the screw of the low gas jet 2 to the stop (Fig. 12.1);

- unscrew both screws by l.25 turns;

- start the engine and warm it up;

- set the throttle control lever to the position corresponding to the minimum speed;

- screw h to set the minimum stable idle speed;

- screws) m 2 set the maximum idle speed;

- adjust the minimum stable idle speed with screw 3;

- repeat the last two operations until a stable, uninterrupted operation of the engine at idle with the lowest possible speed is obtained;

- move the throttle control lever to the maximum engine speed position;

- in case of interruptions in the operation of the engine, unscrew or tighten the screw of the main jet 1 until stable operation is obtained.

The total turning out of the screw of the main jet 1 from the “fully screwed” position should be no more than 1.25 turns;

- additionally adjust the carburetor at minimum idle speed

During many years of operation, as the lever 17, float 11 develops, fuel level adjustment is required, which is carried out by bending the lever 17. This operation must be carried out in a specialized workshop.

The efficiency of the engine depends on the correct adjustment of the carburetor.

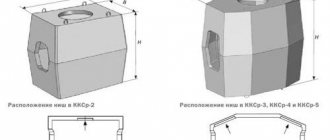

Rice. 12.1. Travel carburetor. 1 - pint of the main jet, - 2 - pint of the small gas jet; 3 - minimum speed screw

Rice. 12.2. Scheme of operation of the carburetor 1 - fuel supply fitting; 2 - upper case; 3 - throttle valve; 4 - small gas needle 5 - air jet; b - lower body; 7 - starting damper; 8 - air filter, 9 - full throttle needle; 10 - atomizer; 11 - float; 12 - fuel valve; 13 - rubber sealing ring; 14 - sealing ring; 15 - adjusting screw; 16 - throttle stop; 17 - lever

Tillage can only be effective if the right tools are used. One of them is just the Luch walk-behind tractor. But they must be applied intelligently and competently, as clearly as possible.

Features of the motoblock carburetor device

The walk-behind tractor is a powerful power mini-unit with additional equipment to perform various functions.

It is often based on a gasoline engine, less often a diesel or electric one. A carburetor is used to ignite the fuel. There are two main types of carburetors:

- Rotary. Differs in simplicity of structure, often found in engines of small sizes (12-15 cubic inches);

- Plunger. The multi-element design is relevant for high-power walk-behind tractors.

Carburetion is performed by the following parts: piston, fuel tank, Venuri tube, fitting (acts as a connector), high and low speed needles.

The piston moves up, creating a vacuum. The carburetor begins to absorb air, which moves through the venturi tube. The created vacuum allows fuel to pass through the connecting fitting from the tank to the engine. Further, the fuel passes around the main needle and through the inlet socket into the venturi.

While pressing the throttle lever, the low speed needle opens up access to gasoline, after which the fuel flow is controlled only by the main needle.

Demanded agricultural machinery "Neva", "Agro", "Ugra", "Oka" is in demand due to its configuration. When it comes to the carburetor of the Neva K-45 motoblock, this is a reliable device that is distinguished by quality and durability. KMB-5 is an older model of the carburetor in the Neva units. Before buying, it is worth clarifying this nuance in order to acquire a truly professional assistant.

Powerful motors on the MTZ (Belarus-09-N) and Neva MB-2 motoblocks are supported by the operation of reliable carburetors that can withstand heavy loads. On the Cadvi MB-1, Cascade and the Pchelka motor cultivator, lightweight carburetor models are used to optimize the functionality of the engine.

Overview of the range

The Georgian Machine-Building Plant has released a series of modifications of the Kutaisi walk-behind tractors:

- Kutaisi Super-600

- Kutaisi Super-608

- Kutaisi Super-610

- Kutaisi Super-612

However, the most popular motoblock model is Kutaisi Super-610.

Kutaisi Super-610

This unit is designed for all types of agricultural work involving various attachments. With it, you can not only plow and cultivate, but also plant, hill, harrow, dig, water, transport goods, mow grass, remove snow and much more.

The unit has proven itself well on clay, loamy, sandy soils and black soil.

Perfectly copes with the processing of virgin lands. The walk-behind tractor is prepared for various climatic conditions, neither precipitation nor temperature changes are terrible for it.

Motoblock Kutaisi Super-610

The four-stroke gasoline power plant ALN 330 with a lower valve arrangement has a capacity of 5.44 horsepower (4.8 kW). Forced air protection protects the motor from overheating, although the instruction recommends making short stops for 20-30 minutes after every 2-3 hours of work on the walk-behind tractor, which will allow the engine to cool.

Modern Kutaisi walk-behind tractors are increasingly equipped with 6.5 hp Honda engines.

The engine is started from a reversible manual starter. The ideal fuel for the ALN 330 engine is AI-92 gasoline. The operating weight of the walk-behind tractor is 105 kg, for a better immersion effect, the kit includes a ballast (additional load or weights) - two cast-iron disks for wheels of 15 kg each and a powerful cast-iron plate under the engine crankcase weighing 20 kg. All parts are quick release.

The kit includes pneumatic wheels with a wide agricultural tread, which increases the patency of the walk-behind tractor.

The depth of cultivation with cutters (4 pcs in a set of saber-shaped) reaches about 12 cm. For the convenience of work, there is an additional transport wheel.

Saber cutters

The transmission is four-speed, there are three forward speeds and a reverse gear. Rod control, adjustable in two planes (vertical and horizontal up to 180 degrees). There is a power take-off shaft on lever control, which allows you to attach any attachments to the walk-behind tractor. The package includes a universal hitch, cutters, lugs, trailer and wheels.

Characteristics

| engine's type | Petrol, 4-stroke |

| Power, kWt) | 4.8 |

| Working volume | 327cm3 |

| type of drive | Dependent |

| Control type | Rod |

| Number of gears | 3 forward / 1 back |

| Oil tank capacity (L) | 0.75 |

| Processing width (cm) | 56-61 |

| Cutter diameter (cm) | up to 30 |

| Weight, kg) | 105 |

Motoblock carburetor adjustment

A situation may arise in which the engine runs unstable.

In this case, it is necessary to adjust the carburetor on the walk-behind tractor. It is worth starting tuning in early spring (after a long downtime of the unit) or late autumn (after heavy loads).

It is better to carry out all repair work in a free and well-lit space. To set up a carburetor with your own hands, you will need a minimum of time and effort. Procedure:

- the engine warms up for five minutes;

- the minimum and maximum throttle screws are screwed in as far as they will go;

- adjust the screws by a maximum of 1.5 turns;

- set the gear lever to the minimum stroke;

- using the throttle adjustment screw, achieve the minimum speed when the engine runs "without failures";

- using the idle screw, adjust the idle speed to the maximum until the engine runs continuously;

- the engine must be running during all manipulations. Only at the end it needs to be muffled and turned on again for control.

If you compare your actions with the instructions, you can avoid errors in repairs. After adjustment, the engine should run silently and without failures.

Other malfunctions may also occur. If fuel does not enter the cylinder, you first need to check its amount in the gas tank. The next step is to check the fuel flow to the carburetor. It is worth removing the hose from the inlet fitting. In most cases, you will need to clean the carburetor of the walk-behind tractor - blockages are removed from the filter of the mechanical cleaner.

Owners of walk-behind tractors should familiarize themselves in detail with the specifics of the carburetor, as well as ways to eliminate breakdowns. The proposed video will help you deal with the problem.

Specifications

The technical passport for the Luch walk-behind tractors states that their length is 150 cm with a width of 60 and a height of 100 cm. The mass of the structure reaches 100 kg. The device can travel at speeds of 3.6-9 km/h. The track width of the walk-behind tractor is 59 cm, and the clearance is 33 cm. The “Rays” are able to climb a slope with a longitudinal slope of 20 degrees. For a transverse slope, the critical value is 24 degrees.

The walk-behind tractor has 2 forward and 2 reverse gears.

Important: Employees must wear ear plugs. After all, the sound volume reaches 92 dB. The cultivator for a walk-behind tractor has a width of 72 to 113 cm. Its diameter is 36 cm.

How to adjust the carburetor of a walk-behind tractor with your own hands

Adjustment of the carburetor of the walk-behind tractor should be carried out periodically in order to properly operate the mechanism. A possible cause of fluctuations in the operation of the walk-behind tractor engine can be a carburetor. To do this, the device is disassembled, cleaned and adjusted (adjusted). Regardless of the brand of carburetor and on which device it is installed, the principle of regulation is the same for everyone. The difference can only be in the number of revolutions.

Owner reviews

Vasily, 33 years old:

“I found “Miracle Techniques” in my grandfather's barn, as I understood after the inspection, the walk-behind tractor had not been used for more than 10 years. Grousers, cutters, a hitch and even a trailer lay nearby. Curiosity and excitement took their toll, and after a month and a half of restoration work, the walk-behind tractor started working. Of course, I replaced the engine, put the Honda. I went over it, cleaned it up, polished it where necessary, turned it off - no one in the district has such an assistant, so what if he went to his thirtieth decade !?

Peter, 41 years old:

“I was consciously looking for Kutaisi Super 610. I remember it from childhood - my father used to have one. Reliable, unpretentious, productive, withstanding snow and rain and a blizzard. I bought two at once, with the aim of restoring into one. It was a lot of work, but I'm happy with the result. And plows, and sows, waters, generally helps out with potatoes - they forgot about the “associated” diseases. The engine has also changed - so there will be fewer maintenance problems, Honda is easier to maintain, there are spare parts, there is fuel, all the oils ... "

Alexander, 39 years old:

“My father in the village has been plowing such a walk-behind tractor for the 20th year, probably. His father repairs it periodically, but the damage is not serious (pulley, spark plug, carburetor bulkhead). Very strong walk-behind tractor, takes any soil, confidently moves forward. Father is advised to change the engine, but he still resists, he still drives ALN30. There are almost all sheds - and a mower, and a pump, a snow blower (made by hand), all diggers-planters. A plot of 32 acres is serviced without problems. An excellent walk-behind tractor, if anyone comes across - take it, you will not regret it. ”

How is the carburetor adjustment of the walk-behind tractor

What should I pay attention to during a motor failure? If a carburetor malfunction occurs, the first step is to check the fullness of the fuel tank and the oil level. If there is enough fuel and oil, then proceed to inspect the candle. To do this, unscrew it and use the ignition to check the spark. Next, they test the flow of gasoline to the carburetor. To this end, remove the hose from the fitting and monitor the flow of fuel. If fuel does not appear, then most likely the filter mesh will need to be cleaned. To do this, the fuel valve is unscrewed and all parts are washed with gasoline. The same is done with the carburetor jet.

Carburetor cleaning is performed as follows. To clean the device, you must first remove it. To easily remove the carburetor, you need to carefully inspect the body of the device and unscrew all the parts on which it rests.

So, remove the carburetor and pour gasoline out of it. Carefully separate all parts of the device (jet, float) for further purge and cleaning. This manipulation is performed by a special cleaner.

In case of severe pollution, you can use the compressor.

After cleaning, thoroughly dry all parts and safely proceed to assembly. After assembly, adjust the carburetor for the walk-behind tractor.

We install the cleaned device using the standard gasket, and fasten it with nuts. Do not forget about the air filter, speed controller and hose for supplying gasoline.

Setting up the carburetor of a walk-behind tractor consists in adjusting it. In order to independently adjust the carburetor, you need to do the following steps:

- The small and full throttle screws must be tightened to the stop.

- Unscrew the low and full throttle screws by one and a half turns (we set the throttle valve to such a position that a gap of the appropriate size is formed between the base and the air duct).

- Start the engine and wait until it warms up.

- With the engine running, set the control lever to minimum speed.

- Achieve smooth engine operation. To do this, you need to make the minimum idle speed using the throttle screw.

- Set the idle speed to maximum with the idle screw.

- Set the idle speed to minimum with the throttle screw.

- Repeat steps 6 and 7 until continuous engine operation begins.

- Put the engine control lever on the gas.

- In the event of an interruption, unscrew the screw that regulates the quality of the mixture, no more than 2.5 turns.

I would like to note that the adjustment of the carburetor on the Neva walk-behind tractor is carried out clearly according to the above instructions. The K-45 device installed on the Neva walk-behind tractor is single-chamber and horizontal. The float chamber is located in the central part. The throttle body is flat.

The Neva walk-behind tractor uses the DM-1K engine, which is produced on. The manufacturer categorically does not use Chinese-made engines. This also applies to the production of a motor cultivator.

Subtleties of operation

Regardless of which modification of the Luch walk-behind tractor the farmers got, you must carefully read the instructions. It is she who will tell as accurately as possible about all the nuances of the design and handling it. It is possible to fill in gasoline of all brands in the AI-76 - AI-95 range. As for changing the lubricating oil, it should be done every 50-100 hours. The exact time is determined individually, focusing on how large the load is.

At the first start, it is necessary to fill the gas tank; of course, the walk-behind tractor must be fully assembled. Break-in time is up to 20 hours. By the end of its gear and motor will adapt to normal load. Before setting the ignition, it is imperative to check the candles. It is because of them that problems and failures often arise.

Experts recommend that you always keep a backup candle at the ready. If necessary, clean the candles from soot; but both when installing new devices, and when cleaning old ones, it is necessary to carefully set the gap. It should be at least 0.1 and not more than 0.15 mm. When putting a new walk-behind tractor into operation, it is imperative to adjust the carburetor. It is also carried out in the event of failures, and when installing a new spare part.

First of all, tighten the screws on the jets until they stop. This must be done more carefully. Then they are unscrewed back 1¼ turns. When this is done, start the engine, warm it up for 20 minutes. When reaching operating temperature, turn the throttle valve to a minimum.

The screw is assigned the smallest stable value of the idle speed. Then find the largest stable value. Repeat these steps again to ensure the stability of the device. To transfer the walk-behind tractor, it is necessary to turn off the engine. When the engine is running, it is very easy to damage certain parts of the apparatus.

For normal forward travel, A-1213 format belts must be worn. These belts are also suitable for Oka and Cascade. In some cases, in order for the drive belts to transmit the necessary impulse, it is necessary to strengthen the gearbox. Important: when overhauling the engine, the need to remove the flywheel does not always arise. This is only required when replacing:

Carburetor Operating Instructions

Gasoline that enters this device must not contain mechanical impurities. All parts are processed exclusively with gasoline. The use of solvent is not allowed, as the elasticity of the washer and rubber parts is damaged.

Use compressed air to dry parts. Cleaning small holes with a wire or needle is not recommended. Installation after repair or cleaning must be carried out evenly so that bending and deformation of parts does not occur.

The float chamber must be hermetically connected to the body. Check the air filter connection before use. There should be no fuel leaks.

Before starting the engine, prepare the carburetor. To do this, you need to make sure that gasoline does not leak from it. To do this, just open the fuel cock. Close the air damper, and tighten the control lever until it stops. Open the throttle valve 1/8 - 1/4 of the maximum stroke. At low air temperatures (below +5ºС), squeeze the drowner until fuel appears from the hole.

During start-up, slightly open the choke, and after warming up the engine, open it completely.

Carburetor care, replacement and repair

Sometimes, in order to bring the carburetor for a walk-behind tractor to a stable, working condition, adjustment is not enough, repair or replacement is necessary.

It happens that the carburetor air damper does not close completely. To eliminate this problem, it is necessary to monitor the operation of the drive. If jamming is found, eliminate them. Moreover, given that the carburetor provides fuel and, therefore, sets the walk-behind tractor in motion, you should carefully monitor the condition of this part and properly care for it.

To avoid serious damage to the carburetor, you must constantly monitor its operation. In addition to adjusting the idle speed, you need to regularly clean the carburetor and replace worn parts. Since the carburetor interacts with the fuel mixture and air, the cause of its contamination can be either in the first or in the second source.

To reduce the degree of contamination significantly, filters can be used, which should be cleaned and replaced as needed. In addition, the quality of fuel also significantly affects. Poor fuel quality can cause damage to parts and premature replacement. If there is a need, a carburetor for a walk-behind tractor can be purchased at the automotive market or a store. Its replacement, adjustment and cleaning is also carried out by specialists.

The carburetor for a walk-behind tractor acts as a node of the power system. Its task is to optimize the fuel until the desired composition is obtained.

The carburetor requires constant monitoring of loads. For its proper operation, regular inspection and competent operation is necessary. Much depends on the configuration of the unit and the quality of the fuel used.

How to handle the carburetor if the walk-behind tractor has not been used for a long time

In this case, you need to do the following:

- Separate the device from the engine.

- Remove dust using a soft brush and gasoline.

- Unscrew the float and fitting.

- Rinse filter and all parts with clean fuel.

- Blow out with compressed air.

- Check that all parts are dry.

- Assemble the device and install on the engine.

The carburetor does not require daily major cleaning or tuning, but it is necessary to monitor its condition for the engine to work flawlessly.

In the event of a malfunction in the motor block engine, the most common cause is contamination of the device. This is very often associated with the quality of gasoline.

The problem may be related to both carburetor contamination and the wire connecting the accelerator pedal to the carb. If, when the wire is disconnected with the engine running, the speed indicators return to normal, then you will need to change the wire.

Description

The device, repair and maintenance of the Ugra walk-behind tractor are the most frequently asked questions on specialized forums. In this article, we will consider these issues in detail.

Motoblock Ugra NMB 1H7

Motoblocks of the Ugra brand comply with all European safety standards and tolerances, they have established themselves as reliable and hardy farmer's helpers. In conjunction with functional attachments, they can be used all year round.

The manufacturer is the Russian enterprise "Kaluga engine" ("KaDvi"), which produces engines, spare parts for tractors, attachments and motoblocks "Ugra" and "Oka".

Carburetor for walk-behind tractor

Along with the engine, the carburetor is one of the most important elements of the walk-behind tractor, the main function of which is to enrich the fuel with air and supply the finished mixture to the engine of the unit. From time to time, the carburetor of an agricultural machine requires adjustment, which will help reduce the amount of fuel consumed and increase the power of the walk-behind tractor. Setting up a carburetor is not difficult, but before work, you should prepare and study the sequence of actions when performing this procedure.

Reverse belt

While on modern walk-behind tractors the reverse gear is switched off using a gearbox that is directly connected to the engine, on the Luch a belt is used to transmit torque .

In fact, it is one of those details that distinguishes the Luch walk-behind tractor from modern technology.

The reverse belt is subject to increased wear, and therefore an experienced beam owner always keeps several belts in reserve at once - sometimes they can be difficult to obtain, despite the fact that this walk-behind tractor is quite common.

Its marking is Z(0)-1400 and it is easier to order it through an online store where there is a pre-order service.

In order not to find yourself in a situation where a malfunction has occurred and you cannot use your Luch walk-behind tractor, it is better to keep belts in an amount of at least two pieces of each type. Such thrift will help you to make quick replacements, even in the field, during work.

In general, a good way to keep all equipment in working order is to have spare consumables for all nodes. This is especially important if such consumables tend to fail quickly.

Motoblock carburetor device - we study the mechanism from the inside

The carburetor for a walk-behind tractor has a fairly simple design. Nevertheless, it should be studied, since in the future it will allow for timely adjustment and self-repair of the unit.

The device of the carburetor available in the walk-behind tractor consists of the following elements:

- a float connected to a needle-type check valve;

- float chamber;

- air mixing chambers filled with fuel;

- diffuser and fuel spray mechanism;

- throttle valve;

- air and fuel valves with installed jets.

The float, connected to the needle valve, plays the role of a kind of regulator of the amount of fuel in the float chamber. As soon as the fuel level drops, the carburetor float drops, which causes the needle valve to open. This helps to get the missing amount of fuel into the float chamber. After the chamber is filled with gasoline, the float rises, at the same time closing the needle valve.

Between the float chamber and the mixing chamber there is an atomizer that dispenses gasoline into the mixing chamber. There, the fuel is mixed with air, which, in turn, enters the carburetor through the inlet pipe. The volume of fuel available inside the float chamber is always a few millimeters below the level of the outlet position. This is necessary so that when the engine of the walk-behind tractor is turned off, fuel does not splash out of the float chamber. This is especially necessary in cases where the walk-behind tractor is located on a slope.

How to correctly set the ignition

The operation of any device begins with the start of the engine and the ignition system must work no worse than a Swiss watch.

But in the event that the functionality of this element is somehow impaired, it is necessary to adjust it.

Before you set the ignition on the Luch, Don, Huter, Pro, Plowman, Champion, you need, first of all:

- Check candles. They are the main reason for the failure of this system. It is also always recommended to have a spare candle with you, in case manipulation, cleaning, does not help. To deal with the candle, it is necessary to turn it out and wipe the electrodes and remove carbon deposits from them.

- Next, you need to set a gap between them.

- Next, put the wire square on the spark plug, and firmly press its body against the cylinder, its head, while turning it away from its own hole, which is located in the cylinder head.

- It is necessary to scroll the crankshaft . This can be dealt with with a starter cord. In a working system, the spark that jumps between the electrodes should be light blue. If it is absent, or has a white - yellow color, the system is faulty.

In this case, you can check the gap between the stator and the flywheel magnetic shoe, it should be from 0.1 to 0.15 mm.

After these simple manipulations, you will get a perfectly working Luch walk-behind tractor. Installing the ignition on it is as simple as setting it up, since it consists of several parts that are connected like parts of a designer.

All grooves are designed in such a way that nothing can be confused, insert the candle on the wrong side or connect the wires incorrectly. After you have adjusted the ignition of the Luch walk-behind tractor, and this part of it is working properly, you can start setting up the next important engine assembly.

Motoblock carburetor adjustment - detailed description of the procedure

There are a number of signs indicating the need to adjust the built-in carburetor of a walk-behind tractor.

These include:

- a sharp drop in the power of the walk-behind tractor;

- increase in the amount of exhaust gases produced;

- starting the motoblock motor with subsequent spontaneous shutdown;

- unstable operation of the engine of the unit at idle;

- rapid increase in the amount of fuel consumed.

There may be several reasons for these failures. Among them is the use of a walk-behind tractor with excessive loads on its mechanisms, as well as a long downtime of the unit without practical use. In any case, timely adjustment of the carburetor of the used agricultural machine will help to solve these problems.

It is quite simple to set up the carburetor of an agricultural machine on your own. Before adjusting, you will need to start the engine and let it run for 5 minutes. After that, you need to directly adjust the carburetor on the walk-behind tractor.

The procedure is performed in the following sequence:

- After preheating, you need to turn off the engine and install the walk-behind tractor in a stationary position. Next, turn the screws that regulate full and low throttle to the stop, then unscrew them 1.5 turns in the opposite direction;

- Next, you will need to start the engine again and warm it up - this should take at least 5 minutes;

- Then you will need to set the engine speed control lever to the lowest speed position - while the engine should be running;

- After that, you need to turn the throttle position adjustment screw to the position at which the walk-behind tractor engine will work most stably;

- Next, you need to turn the carburetor low speed adjustment screw to the extreme maximum position;

- Then you need to turn the throttle screw to the minimum position;

- The last two procedures should be carried out until the engine starts to run smoothly;

- After that, you need to set the engine speed control lever to the maximum gas position;

- At the end, you will need to turn the screw responsible for adjusting the maximum speed by 2.5 turns in different directions to check the stability of the engine. You can learn more about setting up the carburetor in the video.

After setting up the carburetor of the walk-behind tractor with your own hands, you need to check the operation of the unit. If the engine started to run smoothly and consume less fuel, then the carburetor adjustment was done correctly.

Attachment

Kutaisi units are multifunctional agrotechnical devices, with a huge range of work performed. All additional options are possible with the participation of the following attachments developed by the Kutaisi Machine-Building Plant:

- cutter.

A device for loosening the soil. Cutters are saber and "crow's feet". The number of knives on one cutter can vary from 3 to 4. For Kutaisi, saber-shaped L-shaped cutters 21M were originally used. Saber cutters Cutters Crow's feet - Reversible single-hull plow. It is used for plowing virgin lands, autumn arable work, when you need to go deep into the ground as much as possible.

- Single axle trailer. Designed for transportation of bulk and piece goods, its carrying capacity can reach 500 kg.

- Pump. A motor pump that allows you to pump out groundwater from drainage ditches, basements, and irrigate beds.

Water pump (pump)

- Sprayer. It is used to spray plants with various chemical compounds designed to control pests and improve plant growth. The sprayer is attached to the adapter, the necessary pressure is created by a motor pump.

- Okuchnik-digger. This device allows you to cut furrows for planting plants, pile up already planted potatoes, etc. It can also be used to dig up potatoes.

- Mower.

Front, segment and rotary models are offered. Mowers allow you to harvest animal feed, as well as keep an eye on the look of your lawn. Segmented mower Rotary mower Frontal mower Terminator - Rake. This device will not only level the unevenness of the soil after the plow, but will also help you quickly collect hay, straw, etc. at one point.

- Universal hitch. Model STs-15 is used. It is intended for aggregation of various canopies with the motor-block. The universal hitch makes it possible to set the required angle of attack of the canopy and the horizontal. The hitch is attached to the PTO bearing cap with special studs and nuts.

Universal hitch STs00010 -15

- Weighting agents. The kit for the walk-behind tractor includes three weights: 2 discs of 15 kg each, mounted with studs on the wheels and a rectangular plate weighing 20 kg, attached to the walk-behind tractor carburetor.

- Pneumatic wheels.

Equipped with a powerful tractor tread, they are used for transporting a walk-behind tractor, as well as complete with a trailer, mower, snow blower. Pneumatic wheels - Grousers. They are put on the shaft instead of wheels during periods of field work. They perform double work - they transport the walk-behind tractor and additionally loosen the ground with stiffeners welded on the axle.

Modern developments have made it possible to attach the following canopies.

- Snow blowers.

Three varieties are offered: brush, blade and auger snow blower. Brush Shovel Blade Snow Blower - Adapter. Made in the form of a solid frame on wheels with a fixed seat. Turns a walk-behind tractor into a mini-tractor.

- Potato planter. This canopy will completely mechanize the once tedious process of planting potatoes. The tubers are poured into the bunker, where they are captured by the blades and lowered to the desired depth into the ground. A soil ridge of the desired height is immediately formed on top of the tuber.

- Potato digger.

Potato harvesting is also mechanized. Screening (vibrating) or conventional diggers will come to the rescue and in a matter of minutes the crop will be on the surface of the soil, and without loss. Vibrating screen potato digger KM-1 Potato digger - A caterpillar attachment, etc. This canopy is relevant in swampy areas, where, due to the strong viscosity of the soil, there is a low permeability of the walk-behind tractor. The surface of contact with the ground has expanded, the weight is distributed more evenly, the walk-behind tractor moves more confidently and without slipping. Attachments are sold separately.

Cleaning the carburetor of a walk-behind tractor - how to remove blockages yourself?

As a result of intensive use of the walk-behind tractor, over time, a large amount of dust and evaporation products of the fuel mixture accumulate in its carburetor. This is bad for the efficiency of the mechanism, and in order to correct the situation, you will need to thoroughly clean the carburetor.

This procedure is performed in the following order:

- First you need to remove the carburetor from the walk-behind tractor;

- Then it is necessary to drain all the fuel from the float chamber of the device;

- Next, you need to inspect the float fitting. If the fuel flows out of it too slowly, then the fitting will need to be blown out with compressed air from the cylinder. Then you need to turn the fitting by 180 ° - if after that the fuel stops flowing out of the carburetor, then the fuel valve is fully functional;

- After that, you need to check the jets. To do this, you will need to unscrew and remove the screws responsible for adjusting the full and low throttle, as well as disconnect the lower and upper parts of the carburetor body. After that, you need to flush the jets and the fuel cock. For flushing, it is best to use clean gasoline, or blow them with compressed air from a cylinder;

- Next, you need to lay out the parts of the carburetor for their complete drying. The assembly of the carburetor is carried out exclusively with absolutely clean spare parts.

When reassembling the carburetor, it is very important to install the parts in such a way that the spray tube is located exactly against the hole in the top of the carburetor of the walk-behind tractor. After that, you can install the carburetor on the walk-behind tractor.

The methods described above for setting up and cleaning carburetors are suitable for owners of walk-behind tractors from the Pchelka, Agro, MTZ, Cascade, Neva MB-1 and MB-2 brands, as well as other units equipped with K-45 and KMB-5 carburetors.

Maintenance of the motor-block "Ugra"

Motoblock maintenance includes:

- Preparation for field work.

- Daily care after use.

- Scheduled inspections.

- Contacting service centers.

- Preservation of the Ugra walk-behind tractor for long-term storage.

Preparation for operation:

- Checking the fuel level in the fuel tank.

- Checking the oil level in the crankcase.

- Checking the reliability of available fasteners.

- Tire pressure.

Care of the unit after operation:

- Cleaning the Ugra walk-behind tractor from dust and dirt, clods of earth, oil and gasoline stains.

- Washing the walk-behind tractor with water.

- Dry the machine in an open area without direct sunlight.

- Lubrication of units and mechanisms with appropriate lubricants.

Conservation is a period of downtime for which it is necessary to prepare the machine accordingly.

The owner of this heavy equipment must:

- drain the fuel from the gas tank;

- drain the oil from the engine crankcase;

- clean the walk-behind tractor from dirt;

- lubricate components and mechanisms;

- put the walk-behind tractor under cover in a dry, ventilated place.

All about motoblock carburetors

Without a carburetor inside the design of the walk-behind tractor, there would be no normal control over hot and cold air, the fuel would not ignite, and the equipment would not work efficiently.

For this element to work properly, it needs to be carefully monitored and configured.

How is it arranged?

If we consider the carburetor from a constructive point of view, then it is arranged quite simply.

It has the following nodes installed:

- float;

- valve, the role of which is to lock the chamber, it is installed of a needle type;

- diffuser;

- mechanism for spraying fuel;

- chamber for mixing gasoline and air;

- fuel and air valves.

In the chamber, the float plays the role of a regulator responsible for the amount of incoming fuel. When the level reaches the minimum allowable, the needle valve opens, and fuel again enters in the required amount.

Between the mixing and float chambers is a sprayer. The fuel subsequently turns into a single mixture with air. The air flow is transmitted inward through the nozzle.

Operating instructions for motoblock Kutaisi Super 610

Many farmers and gardeners are interested in the Kutaisi Super 610 walk-behind tractor, the instruction manual for this unit. The motor cultivator of Kutaisi began to be produced in the 80s of the last century. They were purchased by the owners of small suburban areas. Now the production of Kutaisi cultivators is carried out under the license of the Italian company and is called Kutaisi Super 610.

Repair and maintenance

Sometimes it is not enough to adjust the operation of the carburetor and a replacement of one of its parts is required.

Most often, the cause of the problem is the air damper, which ceases to close completely. In this case, you will first need to check how the drive works.

If jamming is found, they must be eliminated.

Serious breakdowns can be avoided only if you constantly monitor the operation of the unit and control it. In addition to adjustment, cleaning or simply replacing worn parts is necessary.

The cause of pollution may be hidden in low-quality fuel or dirty air. Filters, additionally installed in the design of the carburetor, can correct the situation.

It is necessary to select high-quality fuel, because it significantly affects the resource of using all elements in the design of the unit. You can learn how to disassemble the carburetor yourself or give it into the hands of specialists. The first way is chosen by those who want to save money. During the operation of the walk-behind tractor, dust and combustion products are collected inside its device, then the efficiency of the element is reduced.

In this case, cleaning can help, which is carried out in the following sequence.

- Remove the carburetor from the walk-behind tractor.

- Drain fuel completely.

- The fitting is inspected, in the case when the fuel is removed from it poorly, then it needs to be blown out. A compressed air bottle is used. After that, it is rotated 180 degrees, if the fuel no longer flows, then it works fine.

- The next step is to check the jets. To do this, you need to remove the screws that are responsible for the gas and remove the carburetor body. The jets are flushed together with the fuel cock. The best remedy in this case is gasoline, after which it is purged with air.

- Next, you need to decompose the washed elements, and then assemble the carburetor in the same sequence.

When assembling, it is important to pay attention to the location of the spray tube, which should be opposite the hole present at the top. Only after that, the carburetor is again installed on the walk-behind tractor.

All described methods are suitable for motoblocks "K-496", "KMB-5", "K-45", "DM-1", "UMZ-341", "Neva", "Bee", "Cascade", Mikuni, Oleo-Mac, Veterok-8 and others.

Cleaning a Japanese carburetor and setting it up is as easy as any other manufacturer's unit. There is no difference, since the design is almost the same for everyone, the main thing is to know the technology.

You will learn how to disassemble and clean the carburetor of an air-cooled walk-behind tractor from the video below.

Motoblock Kutaisi

Motoblocks of Kutaisi were born in the distant USSR in the late 80s. They got their name from the location of the machine-building plant in Kutaisi (Georgia). The brand was developed by the Italian company AKME, which produces a series of similar walk-behind tractors Goldoni (Goldoni). Modern domestic Kutaisi were developed under the license of this company and received the prefix "Super". Georgian engineers slightly rebuilt the walk-behind tractor (the ignition system was redone from contact to non-contact, the modernization also affected the clutch of the unit).

Motoblock Kutaisi

The walk-behind tractor has passed all the checks - by time (more than 30 years of production experience and the unit is still working), GOSTs, has recommended it as a reliable means of small-scale mechanization, indispensable for private use on small plots of land. At the moment, you can get more complete information about work, repairs, spare parts, etc. on numerous forums where Kutaisi-610 is discussed.

Motoblock carburetor device

Knowledge of how exactly the carburetor for a walk-behind tractor is arranged will help you independently eliminate any of its malfunctions, as well as clean and timely adjust the standard fuel unit.

Structurally, the mechanism consists of:

- a float that is connected to an integrated needle locking steel valve;

- float metal chamber with chrome-plated internal cavities;

- an additional chamber required for mixing fuel with air;

- fuel distribution structure equipped with a diffuser;

- adjustable throttle;

- fuel and regular air tubes made of technical rubber.

Depending on the manufacturer and purpose of motoblocks, their carburetors can be equipped with additional elements. But regardless, fuel hula work on the same principle.

One of the most important elements of the mechanism is the float, the main function of which initially is to adjust the amount of fuel necessary for the proper operation of the walk-behind tractor. The fuel itself is in the float chamber, and as soon as its volume decreases, the float opens the built-in needle valve. Through it, the missing volume of refueling fuel enters the chamber, after which the float rises and slowly closes the valve.

The carburetor for the walk-behind tractor is equipped with an outlet channel, which is located in the float chamber. For normal operation of the fuel assembly, the amount of fuel in the regular float chamber must be continuously kept at a level that is several millimeters below the location of the outlet channel.

The atomizer initially plays the role of a kind of fuel distributor, which enters the steel mixing chamber from the chrome-plated float. The latter is needed directly for the enrichment of fuel with air. Pre-cleaned air streams enter it through the built-in inlet pipe.

Peculiarities

The Luch motoblock, like many other domestic cars of recent decades, was the result of a conversion. It began to be made at the facilities of Perm Motors OJSC, which previously dealt exclusively in the supply of helicopter engines. Consumers note that these devices:

- are relatively inexpensive and assembled properly;

- can be used at any time of the year;

- work quietly on all brands of gasoline, even on AI-76;

- equipped with the same attachments that are used for other Russian walk-behind tractors;

- extremely rarely create problems for the owners (only occasionally there are references to the inconvenience and unreliability of individual copies).

Let us consider in more detail how exactly the walk-behind tractor of any model is arranged, regardless of size. The ignition scheme involves the use of special initiating candles. In addition to them, the system includes:

- converter;

- stator;

- magnetic shoe;

- button to disable.

It is useful to consider other components using the example of the MB-1 model. This version, released back in the 1980s, is very simple in its technical structure. But such simplicity can even be considered a virtue. The clutch, which transmits the energy generated by the engine to the gearbox, is made on the basis of a pair of belts. And also in the clutch there is:

- drive, front and rear pulleys;

- gear pulley;

- traction;

- front and rear levers;

- special springs.

The gear assembly changes the gear ratio, while simultaneously transferring rotational energy to the wheels and working tools. The MB-1 model has a chain reducer, which, in addition to chains, includes:

- body (assembled from symmetrical halves);

- switching shaft and handle for its control;

- force output shaft;

- three blocks of stars.

The steering mechanism, thanks to the height adjustment function, easily adapts to specific users. The right side of the steering wheel is complemented by a lever with which the motor is controlled. This lever through a special cable acts on the throttle valve. But on the left on the steering wheel there is a forward lever connected to the pulley of the same name. A little lower is the reverse lever.

The transmission is capable of operating in a pair of forward and a pair of reverse gears. The most important element of the chassis are the wheels; they can be both inflatable and made of solid rubber.

Attention: those farmers who want to achieve the highest effect from equipment should change rubber movers to steel ones, supplemented with lugs. The motor on the walk-behind tractor of this model belongs to the DM-1 type. The supply of a mixture of fuel and air into a single cylinder occurs after its preparation in the carburetor.

How to adjust the carburetor on a walk-behind tractor?

In the technique of different manufacturers, the adjustment of the carburetor of the walk-behind tractor is carried out in different ways. Below we will consider how to correctly and accurately set up fuel units in agricultural units of different brands.

Motoblocks brand Cascade

The complete set of most branded models manufactured by the Cascade brand includes carburetors of the KMB-5 brand.

To configure this fuel assembly, you must:

- Drain the remaining fuel from the factory float chamber;

- Open the fitting and let air into the fuel assembly;

- Adjust the position of the throttle damper in such a way that a neat 2 mm gap is gradually formed between it and the air duct located under the damper;

- Tighten the bolts responsible for adjusting the fuel supply;

- Start slowly unscrewing the screws one by one until the speed of the power unit decreases;

- Screw the screws back in slowly one by one.

We adjust the KMB-5 carburetor on the Neva walk-behind tractor

The provided scheme will allow you to easily and simply adjust the carburetor of the KMB-5 model to the Neva walk-behind tractors on your own.

This guide is very clear and simple. By following each step clearly, you can easily resume the operation of this device. Remember that in order for your unit to serve you faithfully for many years, you must definitely do the following things:

- Perform ongoing unit diagnostics.

- Perform regular oil changes.

- Adhere to all operating conditions.

These are key actions that will help extend the performance of all elements and keep your equipment in shape. So stick to these simple rules and enjoy the high-quality and efficient operation of your walk-behind tractor.

Source

Motoblock carburetor cleaning

Frequent failures in the operation of the power unit of the walk-behind tractor indicate the accumulation of blockages inside its carburetor. This fuel assembly constantly interacts with engine oil, gasoline and air. They contain solid fractions, resin and small debris that can be deposited on the walls of the carburetor chambers and inside the fuel channels. In this regard, the carburetor needs regular cleaning, especially if low-quality fuel is used to refuel the agricultural unit.

Before directly flushing the carburetor of the used walk-behind tractor, you need to dismantle the regular air filter and rinse it thoroughly in clean gasoline. After that, the part will need to dry. The operator should also inspect and clean the spark plug. If a thick layer of soot has formed on its cap, then this indicates oil leakage.

The next course of action should be:

- First you need to carefully remove the idle carburetor from the factory device and completely drain the remaining fuel from the standard float metal chamber;

- Then you will need to inspect the built-in fuel fitting. If air does not pass through it, then the fitting must be blown with compressed air from the purchased cylinder;

- Next, the operator must examine the condition of the float metal chamber and the "tongue" needed to adjust the position of the float. The operator must check the level of the amount of refueling fuel that enters the chamber - its level must initially be at least 3.5 cm;

- After that, you will need to remove the needles responsible for setting the small and full gas - this is necessary to completely flush the jet;

- Next, you need to unscrew the bolts and disconnect the standard upper part of the factory carburetor from the lower one. After that, the operator will be able to thoroughly flush the built-in fuel supply valve;

- Then it is necessary to blow the jet with air from the cylinder. This and other elements of the carburetor must not be wiped with a rag with pile. Otherwise, the risk of damage to the chrome coating of the walls of the fuel assembly will increase;

- After all the parts of the standard carburetor are completely dry, it can be assembled.

Immediately after installing the fuel unit, the operator must configure it and smoothly start the walk-behind tractor motor. Next, the user will need to check the operation of the node. If the built-in engine runs as stable as possible and does not make extraneous sounds, then the cleaning and tuning of the standard carburetor were performed correctly.

How to change the seal

Another important point that concerns the repair of a walk-behind tractor is how to change the oil seal on the gearbox.

This is a fairly simple task that does not cause big problems for the masters of their craft, but those who first encountered this and are not familiar with the design of both the walk-behind tractor and the gearbox specifically cannot always cope.

Therefore, first of all, it is worth studying the theoretical part , namely the details that make up this assembly.

The gearbox housing consists of two halves. They are forged from steel and fastened with bolts, a rubber gasket is installed between them for sealing and sealing. Steel squares are welded to the body, which, in fact, form the supporting frame of the entire device.

People involved in construction and gardening cannot do without additional equipment. The garden trolley is your indispensable friend and helper.

Special equipment is often required for all kinds of work in the agricultural and construction sectors. It's all about the universal bulldozer T-130.