Gantry crane (KK) is a multifunctional equipment for various sites and facilities where lifting operations are carried out constantly.

The technical characteristics of the KKS-10 gantry crane are the reason for the demand and popularity of this model in the country.

KK is produced by many domestic ones, Bureysky, Byvalovsky BMZ, Leningrad GMO, Moscow MMZ No. 5, Velikoluksky VOMZ, Uzlovsky Plant, etc., and foreign crane factories.

Gantry cranes - description, general specifications

The gantry crane is a bridge type unit.

The horizontal beam along which the load moves is structurally related to the bridge group of lifting mechanisms.

The main difference is that KK can move on rails by itself .

Outwardly, KK resembles mounting goats, hence the characteristic name.

The average service life of gantry cranes is about 20 years, MTBF is ≈ 3,000 cycles.

Application and arrangement of QC

Gantry lifting mechanisms are indispensable in places where the entrance of the rest of the lifting equipment is problematic or excluded.

Occupying a minimum of space on the ground, the unit covers a large area for moving goods.

Application:

- warehouse and industrial territories , cargo yards;

- factories - polygons for the manufacture of metal structures, reinforced concrete products (KKM-20);

- transshipment of containers at freight stations, railway junctions, seaports (КК-16/20);

- work with logging , wood (LT-62);

- installation of prefabricated industrial structures and equipment (KK-12.5);

- maintenance of locks , dams, thermal and hydroelectric power plants;

- in the ship - and shipbuilding (production of large ships, fixing parts of the hull during welding).

Gantry lifting mechanisms are equipped with those load grippers that correspond to their purpose.

The operation and maintenance of the KKS-10 crane is prohibited in places where combustible or explosive substances are stored.

Work restrictions :

- the boundaries of the working area - the space inside the console (span);

- KK cannot be used on slopes.

The general scheme of the gantry crane with a description :

- crossbar (truss, beam) - span structure.

The bridge of light and medium CC is single-block, heavy - two-block. The beam can be lattice or solid-walled of different sections. It may have 1 or 2 consoles, or not have them at all (console and non-console cranes); - supports - rigid, spatial, flexible or flat. If the spans are <25m, then all the supports are rigid, with undercarriages fixed at the bottom of each. With large distances between the rails - one leg is fixed rigidly, and the 2nd is hinged. Each support includes 1 or 2 posts;

- crane ( cargo ) carts (or electric hoist) equipped with a lifting mechanism on which the load is attached. Cargo trolleys are either monorail or double rail. Double-rail carts move along both belts - upper and lower, and single-rail - only along the lower one;

- electrical equipment . The power supply of the KK is from the external network via trolleys or using a flexible cable. The cable is wound onto a cable drum fixed on one of the crane supports;

- crane rail tracks - ground, R43 / R24 (R50 / R65) rails are installed on wooden (reinforced concrete) sleepers on a gravel pad. The rails must be with grounding and dead ends. Movement is due to double-flange wheels mounted on supports. The track size is equal to the span of the crane.

In addition to structural elements, the gantry crane device includes mechanisms for moving the entire crane and trolley, and a lifting mechanism.

The function of lifting the load is carried out by a cargo trolley (w/w>5t) or a hoist (w/w<15t).

It is possible to combine a cargo trolley with an electric hoist on one mechanism - work with heavy loads is carried out from the trolley, and additional work of lesser severity is carried out with the help of a hoist.

All runway gantry cranes have anti - theft grippers designed to keep the heavy and tall hoist from falling when subjected to wind loads . _ _

Chassis KKS 10

Support rollers for crane KKS-10

Gantry crane KKS-10 is equipped with a sufficiently large number of rigid fasteners in the chassis. The main wheel is planted on the bores of the frame channels. The transmission is mounted on the axis of spherical roller bearings.

The main gear is constantly in coupling with the wheel crown. The bearings that control the rotation of the shaft are connected to the low-speed part of the clutch reduction shaft. A safety guard is used to keep the moving swivel parts of the drive cart clean and operational.

The undercarriage is very convenient with additional racks and the ability to independently move the crane. This is especially appreciated in complex terrain of warehouse yards and broadband railway loading yards. Installation and movement of a crane with rigid mounts in many cases is possible without dismantling the equipment and wasting time on its reassembly.

Classification

According to their purpose, CC can be divided into 3 groups:

- general purpose - reloading, used for loading / unloading various cargoes in open production / storage areas and indoors such as hangars, load capacity = 3.2-50t;

- construction and assembly : assembly of industrial equipment, shipbuilding, installation of large-sized concrete products, supports and trusses of bridges, capacity = 300-400t.

Both categories are mostly equipped with hook suspension, span length = 8-80m, lifting height = 7-30m.

- special : shipbuilding, hydroelectric power station, thermal power station, maintenance of dams, locks. They are equipped with special grippers: grabs, electromagnets, pincer grips, additionally mechanized with a mounting boom, a jib crane, etc.

Special cranes of large standard sizes are produced, which can be calculated together with the project of the structure being built, for example, a hydroelectric power station or a bridge.

Carrying capacity - up to 900t, span - up to 130m, lifting height - up to 80m.

Gantry cranes are self-erecting , the rest are mounted using special equipment.

Different standard sizes of KK are produced, the models have a wide range of technical parameters:

- lifting capacity - from 5 to 1600 tons;

- lifting height - from 3 to 100 m;

- spans - from 20 to 130m;

- lifting speed - from 0.1 to 32m/min;

- movement of cranes - up to 100 m/min, trolleys - up to 40 m/min.

By carrying capacity all models can be divided into 3 categories :

- 5-10t;

- 12-50t;

- Cranes with bolt prestressing, with lifting capacity from 15 to more than 50 tons.

Preferred applications are gantry cranes with flexible load suspension - hook , as well as clamshell (KKTGK) and magnetic (KKM).

Some models have the possibility of lengthening the crossbar and supports due to inserts. This allows you to change the payload from 15 to 50t, the span from 32 to 62m and the lift height from 7 to 30m.

About other lifting mechanisms on the site: truck cranes Liebherr, Ivanovets 25, Galichanin 25, truck crane based on MAZ-5337, Tadano manipulator, pneumatic wheel crane KS-5363, crawler cranes MKG-25BR and RDK-250, tower crane KB-403 and details about overhead crane device.

Control

You can control the lifting and movement of KK cargo from the ground or from the cab.

The electric method is from the crane operator's cab. From a height, cargo of any size is clearly visible, the cabin can be equipped with an on-board computer for more accurate placement of cargo.

Mainly used for lifting capacities >10t and requires an experienced crane operator.

Operation of KKS-10 at temperatures below -40ºС is prohibited: • lubrication of units thickens; • Moisture particles that get on the rubbing surfaces freeze, causing serious damage during operation.

Cranes with this type of control are registered with the technical supervision authorities without fail. The cab of the crane operator can be stationary or mobile .

The fixed one is attached to one side of the crane and is recommended for small spans and lifting heights.

The mobile cabin is mounted to the mobile crane trolley, which is convenient for long spans and lifting heights.

control the process from the ground using a wireless or pendant control panel. This method is more often used indoors with small dimensions of cargo, having a sufficient view from the floor.

Remote control of the mechanism does not require additional education of employees.

For gantry cranes without a cab with a lifting capacity of up to 10 tons registration with the technical supervision authorities is not required

Light crane KKT-5

KKT -5 - K ozlovy Kran with T elfer (electric hoist), g / n = 5 t . They are used for work with light or medium loads (2-10 tons), in construction, industrial hangars, shipbuilding.

OPI, PBI and VBI (general industrial, fireproof, explosion-proof use) for any lifting operations with a load weight of ≤ 5t.

Gantry crane 5 tons - 2 console, lifting mechanism - el. tal, (3 phases, alternating current, voltage = 380V, current frequency = 50Hz).

Gantry crane KKT 5 - specifications :

- lift height = 7.1-11.2m;

- wind load - up to degree V (inclusive);

- span = 6/9/12/12.5/16/18/20/22/25/32m;

- current lead - cable drum, cable carabiner, trolleys (by special order);

- weight = 16-50t;

- lightweight KKT-5 works both in open areas and in the premises of production bases, factories and warehouses;

- control with a remote control.

Gantry crane self-erecting KKS -10

KKS-10 - two-console KK - modernization of the previously produced KKU-7.5 and KKU-10.

The lifting unit of the bridge type on supports, moves along the rails of the crane runway on wheels with flanges.

KKS -10 can be equipped with different working equipment :

- hook - standard;

- grab - transportation of bulk cargo loading within the working platform;

- electromagnet - for working with metal.

The KKS-10 crane device has its own characteristics and technical characteristics :

- The supports and the bridge have a lattice structure, which lightens the weight, while maintaining the strength and operating parameters of the unit (load capacity, speed, etc.).

- Cargo trolley - monorail, suspension type. Above the monorail, a grating was made for passage along the entire length of the bridge.

- To avoid loosening of the mechanisms of movement of the cargo trolley and cab, special rollers are installed, fixed on the main frame with support on the lower chord of the bridge.

- Control method - from the floor / from the cab.

- Repair platforms are mounted on the crane console.

- The security system consists of: limit switches, tilt sensors, buffer devices, wind pressure alarm, sound alarm.

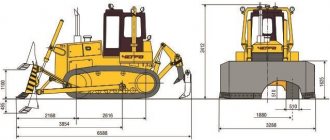

KKS-10 - technical characteristics:

- load capacity 2-10t;

- lift height = 7.1-11.2m;

- wind load - up to degree V (inclusive);

- span length = 14-32 meters;

- current lead - cable drum, cable carabiner, trolleys (by special order);

- weight = 42t.

Gantry crane KKS-10

Gantry (or overhead) cranes are produced by many special equipment factories, the largest of them in the Russian Federation are located in Moscow, Rostov-on-Don, St. Petersburg, Yekaterinburg, Novosibirsk, etc.

Photo of gantry crane KKS-10

Application area

A gantry crane is a unique and indispensable machine in cases where it is difficult or impossible for other lifting equipment to approach.

Occupying a comparatively minimal space on the ground, it can cover large areas with perfect loading and unloading precision.

Gantry cranes KKS-10 are used both in construction and in all other places where it is necessary to work with large loads:

- At railway stations.

- at the cargo port.

- In open warehouses.

- In the construction of vast complexes.

- In loading areas of industrial zones.

- In the arrangement of large engineering structures.

- For maintenance of hydraulic systems.

Model Features

KKS-10 in different configurations can have the following distinctive features:

- For ease of use in different purposes, KKS-10 gantry cranes can be manufactured with different span lengths - standard or individual by agreement with the customer.

- Vertical supports can be equipped with additional posts with a constant panel spacing.

- The operator's cab can be both fixed and movable along the length of the bridge.

Overall dimensions of the crane KKS-10

In addition, the crane can be equipped with various working equipment:

- Kryukov for the standard method of capturing cargo with a KKS-10 zk crane.

- Clamshell for transportation within the working platform and loading of bulk cargo.

- Electromagnetic for working with metal cargo, in particular scrap metal.

IMPORTANT! The gantry crane is adapted to work in a climate of mid-latitudes and easily withstands both frost and high temperature conditions.

Photo KKT and KKS

Different models of gantry cranes are shown in the photo.

Construction device

The working mechanism of the KKS 10 gantry crane is:

- a pair of gearboxes;

- running drive wheel;

- ring gear;

- drive shaft;

- gear;

- electric motor;

- bearing shell;

- intermediate shaft;

- brake mechanism;

- gear clutch;

- brake pulley.

An equally important unit of the working mechanism of the KKS 10 gantry crane is the brake.

The working life of KKS 10 gantry cranes is affected by the quality of installation, it should be performed only by the manufacturer's specialists.