The feasibility of using a cultivator

(1 vote, average 5.00 out of 5)

In practice, the commonly used cultivator treatment is: continuous, inter-row and special purposes.

A continuous tillage cultivator differs from a plow in that it loosens the soil layer without turning it over. The main task of a cultivator of any variety is to carry out cultivation. A shallow dense layer of earth moves to the surface and turns into finely lumpy in structure, the rise of the ridge does not exceed 4 cm. The layer is loosened, crushed and mixed. At the same time, the field surface is leveled, the soil receives the necessary fertilizer. The layer loosened with the help of a cultivator solves several problems:

- prevents the evaporation of moisture;

- forcing the ingress of heat into the ground;

- provides an optimal mode of microbiological processes;

- provides access to beneficial trace elements and nutrients.

Cultivator KPS-4

Before considering the technical characteristics of the KPS 4 cultivator, it is necessary to study this model and its characteristic features. Such a steam unit belongs to the category of attachments, which are most often used with popular models of tractor equipment - MTZ-80.82, as well as T-40.

The product is designed for loosening the surface of the earth, which allows you to effectively remove weeds and simplify the subsequent application of fertilizers. The product belongs to the category of steam, as it is used for continuous processing of agricultural land.

The cultivator helps till the soil

Description, photo

It should be noted that if the device is used with additional equipment, it can be used for inter-row cultivation of fields after the necessary adjustments of the KPS 4 cultivator are made. This is extremely useful in cases where it is necessary to remove weeds and prepare the soil without causing harm available plants.

The product is capable of processing the earth with a depth of 5-12 cm, which guarantees high efficiency of manipulation. In the process of work, it loosens the top layer of the earth to the state of small clods, quickly destroys the roots and shoots of weeds, and also contributes to the general leveling of the field surface.

The use of this kind of equipment allows you to achieve the following advantages:

- reduce the number of weeds;

- improve soil permeability to air and water;

- create optimal conditions for plant germination.

The unit significantly increases the germination of crops and, accordingly, the volume and quality of the crop, which made it incredibly popular.

In terms of its effectiveness, it significantly exceeds manual processing methods, and does not require high-powered models of tractor equipment for use.

The device of the unit, the principle of operation

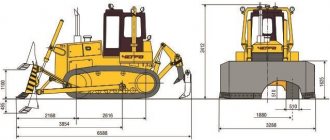

As you can see in the photo, the product has a simple and reliable design, which allows you to guarantee a long service life. The internal structure of the product, as the diagram shows, provides for the presence of several key elements at once, as well as an impressive list of auxiliary components.

Be sure to read: Motoblock Zubr 8 hp

Among the most significant are:

- product frame;

- universal lancet paw;

- working bodies;

- hydraulic cylinder;

- harrow depth control.

Attention deserves a rack with a spring, a stand, fasteners, holders, and other important components of the device. It is important to consider that the manufacturer produces a mounted and trailed version of the equipment. It should be remembered that for the operation of trailed products, it is necessary not only to attach them to the mechanism, but also to connect the hydraulic system.

Cultivator scheme

The principle of operation of such equipment is extremely simple and allows you to effectively process even large plots of land. He assumes that the tractor, together with the raised cultivator, gets to the place of work, after which it is lowered to the surface. The design of the working bodies provides for the possibility of adjusting the angle of inclination and, accordingly, the depth of processing.

In the process of loosening, the working bodies cut off the roots and shoots of weeds, which makes it possible to prepare the field for sowing the desired plants. When moving, the top layer of the earth rises along the paws of the product and crumbles to the desired fractions when falling, which allows it to be evenly distributed on the surface.

The device of cultivators.

The cultivator is mounted from the following assembly units:

- frame;

- working bodies - milling knives, discs, lancet and ripping paws, spring or rigid S -, C - shaped racks;

- attachment system of working bodies: plates, paw holders, beds;

- wheels - running or supporting, depending on the type;

- equipment and mechanisms to bring the structure from the transport position to the operating mode and vice versa;

- adjusting devices for lowering the working bodies to the desired depth and setting a certain row spacing;

- blocks for hanging harrows;

- steering gear.

Classification of cultivators.

By appointment.

By purpose, cultivators are divided into four groups:

- for continuous processing;

- for inter-row cultivation (rowed) soils;

- special purpose;

- universal.

Cultivators for continuous tillage quickly prepare almost any land plot for further sowing. A working machine in motion performs disking, crushing and digging of plant residues, levels and compacts the soil (using a chopping roller with a 3-row tooth harrow). The bottom layer of soil must remain intact, the depth of processing is adjustable. The units of this group are designed to destroy weeds and loosen the soil in preparation for sowing, as well as to care for fallows.

Cultivators for inter-row tillage are in demand in areas where row crops are grown. During the growth period, plants carry out 2-4 inter-row treatments. Row spacing 45-90 cm, sometimes more. The purpose of such cultivation, in addition to the destruction of weeds by cutting and sprinkling with earth, is to carry out root feeding of plants and loosening of the earth.

Special cultivators are used in garden, forest areas and as anti-erosion. Such units in the operating mode should eliminate at least 98% of weeds and loosen the soil without transferring wet layers to the surface.

Universal cultivators perform two or more tillage procedures at once. An urgent task for this series of machines is to stubble the stubble to a shallow depth and to prepare optimally loosened soil in several passes. In order to warm up the soil as quickly as possible before pre-sowing cultivation, these cultivators are used to loosen and ventilate it. This should mainly be done in the spring, because the friendly shoots of spring (yielding crops in the year of sowing) crops predetermine the thermal regime of the soil.

Cultivators, purpose and classification

⇐ PreviousPage 6 of 6

A cultivator is an agricultural machine for tilling the soil. Cultivators are divided into steam

and

tilled

. Steam cultivators are used for continuous tillage before sowing, and tilled cultivators are used for processing crops. With the help of cultivators, loosening, weed control, moisture conservation, and hilling are carried out. Unlike the plow, the cultivator performs loosening without turning the layer.

Cultivators can be equipped with passive (fixed) blades that perform work due to traction, as well as with active (driven) blades. According to the type of drive, manual cultivators, motor cultivators, cultivators aggregated with a tractor are distinguished.

A cultivator is a power unit designed for tillage with cutters. If we compare a motor cultivator with a motor block, then the second one is more powerful and has more attachments in its arsenal and, accordingly, is more functional; walk-behind tractors have a gearbox and are capable of transporting people or goods in a trailed trolley. Due to the greater power, the walk-behind tractor can perform more complex work than a walk-behind tractor, however, the walk-behind tractor is much heavier, and a person gets tired faster. Motor cultivators provide the opportunity for productive work in limited areas of the territory, between rows, in flower beds and near trees.

Modern motor cultivators are equipped with various types of compact engines - gasoline two- and four-stroke, diesel, electric with operation from the mains or from a built-in battery.

Motor cultivators are used everywhere, from small and medium household plots to large farms. Based on this, manufacturers produce light, medium, professional (heavy) motor cultivators.

28. Working bodies of cultivators, their application depending on tillage.

Cultivators are agricultural tools for surface loosening of the soil (without wrapping) and the destruction of weeds. They can also be used for applying mineral fertilizers and cutting irrigation furrows.

Cultivators are supplied with a set of interchangeable working bodies. The main working bodies are flat-cutting, universal and loosening paws.

Single-sided flat cutting shares

(razors) are designed to kill weeds.

Lancet flat cutting shares

cultivators are well suited for killing weeds and loosening the soil to a depth of 4-6 cm without carrying the lower wet soil layer to its surface.

Lancet universal shares

used for continuous and inter-row tillage to a depth of 14 cm. They cut weeds well and crumble the soil, partially bringing the wetter layers to the surface. Lancet universal paws differ from flat-cutting ones in the crumbling angle - for universal paws it is 25-30 degrees, for flat-cutting paws - 12-18 degrees. The grip width of such paws is 220 - 385 mm.

chisel paws

used for loosening the soil to a depth of 15 cm. They are performed as a single unit with a rack. The grip width of such paws is 20 mm.

Feeding knives

used for loosening row spacing and embedding fertilizers into the soil to a depth of 16 cm. To level the grooves that remain after the knife paw, a second loosening or weeding paw is installed behind it.

Okuchniki

designed for cutting ridges, destroying weeds between rows and filling weeds in protective zones. They cultivate the soil to a depth of 16 cm, while the height of the ridges can reach 25 cm.

Arychnik furrow cutters

differ from hillers by the presence of a funnel for applying mineral fertilizers. They are used for cutting irrigation furrows up to 20 cm deep for inter-row cultivation of tilled crops.

Needle discs

used to break the soil crust and kill weeds in protective zones. Disc needles enter the soil to a depth of 4 cm and shift the surface layer by 1-2 cm. Discs are made with a diameter of 350, 450 or 520 mm.

Boronki

used for loosening the soil in row-spacings and protective zones. Spring teeth are attached to the frame, which, for better copying of the relief, is pivotally connected to the bed of the cultivator section.

The working bodies of cultivators are attached to racks rigidly or pivotally connected to the frame.

Steam cultivators.

By purpose, cultivators are divided into steam (for continuous tillage), tilled (for inter-row cultivation) and special.

Steam cultivators are used for tending fallows and preparing the soil for sowing. Spring pre-sowing cultivation of the soil is carried out a few days after harrowing to the depth of seeding to destroy weed seedlings and create a compacted bed for seeds. The unevenness of the depth of processing should not exceed 1 cm. After cultivation, the top layer of soil should be finely cloddy, and weeds should be completely cut. The bottom of the furrow and the surface of the field after cultivation should be even, the height of the ridges should not exceed 4 cm. During cultivation, the lower layers of soil should not be brought to the surface. For better leveling of the soil and moisture conservation, continuous cultivation of fallows and fallows is accompanied by harrowing. KPSh-9.6, KPSh-12, KPG-4

Row cultivators.

Row cultivators are used in the care of row crops, i.e., they carry out inter-row cultivation. With their help, weeds are destroyed, the soil is loosened between rows and rows in order to preserve soil moisture, improve the air and nutritional regime of plants, and feed plants. Inter-row processing of some tilled crops (for example, potatoes) consists in their hilling.

31. Hydroseeder -

a machine for hydroseeding grass, mounted on a truck chassis, the equipment of which consists of a tank with a platform for the operator, a mixer for the working mixture of grass seeds and other materials, a hydrothrower, a pump and other equipment for applying the working mixture to the slopes of the subgrade.

Action

The drive from the thruster through the power take-off shaft and the articulated telescopic shaft is transmitted to the pump, which causes the creation of a vacuum pressure on the suction pipe. Depending on the installation of the 3-way valve located at the bottom of the pump, suction takes place through the connection on the suction pipe (during filling the tank) or from the tank of the machine (emptying the tank).

⇐ Previous6

Recommended pages:

Use the site search: