ZIL-157 can now be seen rather in the cinema than on the roads of the country, although the car has become not only the pride of the Likhachev plant, but of the entire Soviet automobile industry. The history of its creation began in 1954, when the Stalin plant began developing a 3-axle all-wheel drive truck for army needs.

The army needed powerful and reliable equipment. The ZIS-151, which appeared in the post-war years, no longer coped with the tasks, but was taken as the basis for the creation of a new Soviet truck. The new ZIL was put into mass production already in 1958. The car was perfect for the 60s. This was recognized in the world (grand prix of the international exhibition) and in the Soviet country (it was used not only in the army, but also in the national economy).

Interior and exterior

The cab was borrowed from the prototype of the ZIS, it was improved, but everything else in the truck underwent a radical alteration. The defense order was executed taking into account the army load, so all the features of the new truck are associated with increased endurance, maneuverability and reliability.

Outwardly, the car began to look harmonious: an elongated and slightly pointed “nose”, wide flat fenders, 6 single wheels, round headlights on the side fenders, protected by a metal grill. In the steering, the designers installed shortened bipods to reduce the force of blows transmitted to the hands, telescopic shock absorbers increased the smoothness of the ride, a water radiator with an electric motor was supplemented with a windshield blowing system, new seats were made with adjustment.

The body of the car was a wooden platform covered with longitudinal metal ribs to protect against abrasion. The sides were assembled from wooden plates 20x80 mm. The front side was attached motionless, and the side and rear folded back, completely opening the body platform.

2 fuel tanks - 150 liters and 60 liters, with a full refueling, the car can cover more than 500 km.

AutoGurman

ZIL-118 "YUNOST" - REPRESENTATIVE CLASS BUS

In the late 50s, Nikita Sergeevich Khrushchev began a struggle with privileges. It was expressed, in particular, in the fact that the number of officials entitled to use personal cars was sharply reduced. Cars of old models - ZiS-110 and ZiM - were transferred to taxi companies and converted into fixed-route taxis. The release of the new ZIL-111 relative to the original plan was reduced by 10 times.

This decision jeopardized the collapse of the unique team with a high production culture that had developed at ZiL, because when switching to piece production, a significant part of the workers would have to be reduced. In addition, being produced in small batches, the ZIL-111 parts would have an extremely high cost. There was only one way out of this situation - to create a more massive car with the same components and assemblies on the basis of the ZIL-111.

It would be profitable to produce more than one thousand such machines a year, and in order to meet the needs of the country and export, according to tentative forecasts, it was required to produce 4-6 thousand machines annually. Guided by these considerations, at the end of 1959, the initiative group put forward a proposal that, using the components and assemblies of the ZIL-111, to develop a project and build a prototype of a multi-seat passenger car for various fields of application, the successful testing of which would give grounds for deployment its serial production in sufficiently large quantities.

The main idea was to create a completely new type of comfortable multi-purpose passenger car with beautiful external shapes and interior decoration due to a more spacious wagon body layout than that of a limousine and the rational placement of passengers in it.

"Youth" was developed from scratch under the factory index ZIL-118 . The name of the new car proposed by the young designer T. P. Kiseleva reflected not only the age of most of the developers, but also meant the emergence of a promising direction in the production activities of the automobile plant. Moreover, in the history of ZiL, this was the first and almost the only case of giving a car its own name - the ZIL-5301 "Bull" later became another such example.

The load-bearing body, which, with a 3760 mm wheelbase, was 6840 mm long and 2110 mm wide, accommodated 17 passengers. All seats were seated. The space between the outer and inner steel facing panels of the body, connected to the load-bearing frame by welding, was filled with non-polyurethane to achieve good thermal and sound insulation of the passenger compartment. Between the passenger compartment and the driver's compartment there is a partition with a glass upper half, the middle part of which is movable. The engine compartment, which occupies space not only to the right of the driver's seat, but also some part in the passenger compartment, is closed by a hood equipped with two folding parts that fly around access to the power unit. The instrument panel and steering wheel were transferred to the "Youth" from the ZIL-111 passenger car. The driver's compartment is equipped with a separate door located on the left, and a soft seat with longitudinal and vertical adjustments. The useful length of the passenger compartment of 5300 mm and a width of about 1760 mm made it possible to comfortably accommodate 17 people on soft, separate, non-adjustable seats.

The convenience of boarding passengers in the cabin was ensured by the fact that the width of the entrance door opening, located on the right side, reached 880 mm, and the height of the lower step from the ground did not exceed 400 mm, while the height of the inner step was only 260 mm. In addition, for free passage into the cabin, the seat closest to the front door could be easily folded back.

Excellent visibility for the driver and passengers was provided not only by the wind, side and rear windows, but also by the upper windows installed on the roof slopes, equipped with tinted windows. The third door, located in the rear of the body, made it possible, if necessary, to use the space freed up after dismantling the last row of seats for luggage. The same circumstance ensured the loading of stretcher patients during the conversion of the car into a sanitary modification.

The total height of the passenger compartment (1395 mm in the front and 1335 mm in the rear) was made comfortable enough for landing, but did not allow the transportation of standing passengers, which excluded the possibility of overloading the car and determined the low overall height. The body of the ZIL-118 is equipped with a heating system that uses the heat of the coolant of the engine cooling system, ventilation and a device for blowing the windshield. In warm weather, fresh air enters the driver's compartment through sliding vents installed in the door and the right window (on the first samples only through the vent in the door), and passes into the passenger compartment thanks to the side windows lowered by 200 mm. If this was not enough, then the rigid central panel mounted on the roof, when moved back along the guides, opened an opening with dimensions of 680 × 1830 mm.

The windshield was equipped with a washer and two wipers. The driver's compartment was equipped with a central rear-view mirror, sun visors, an additional microphone device and a dome light. Passengers of the Yunost could use ashtrays, coat hooks, lamps located above the seats and the front door, as well as a radio set with four loudspeakers. For stable operation of the radio, a telescopic antenna was installed above the windshield, which was manually controlled from the inside. The car had an electric clock. The picture was complemented by a relin or carpet flooring.

The wide use of plastics, light alloys of stamped seamless and bent power elements in the design of the ZIL-118 made it possible to use most of the serial units of the ZIL-111 passenger car without additional effort. Transmission and chassis elements were borrowed from the limousine, including power transmission, suspension, braking system, steering and wheels. Installation of a reliable, unpretentious, modern truck engine at that time, which is essentially simplified and derated to 150 hp. version of the ZIL-111 engine, allowed the ZIL-118 to easily accelerate to 120 km / h, have low operating costs due to the use of relatively cheap low-octane fuel. With a 100 mm cylinder diameter and a 95 mm piston stroke, the engine had the same working volume as the Zil-111, but the compression ratio was reduced to 6.5 times. Subsequently, such an engine will be installed on the ZIL-130. Two fuel tanks with a total capacity of 160 liters, located in the rear of the body, provided a cruising range of 575 km.

The use of automatic hydromechanical transmission simplified the control of the car, ensured its smooth start and fast acceleration, reduced wear on the engine and power transmission mechanisms. After careful preparation, in March 1962, factory tests of the ZIL-118 prototype began. To determine the operational characteristics of the machine, to assess its comfort and reliability of the units, laboratory road and run tests were carried out in many regions of the USSR, in various climatic zones.

An excellent opportunity to test the design in extreme circumstances was given by intercity runs along the routes: Moscow - Rostov - Sochi - Yerevan - Tbilisi - Krasnodar - Crimea - Moscow and Moscow - Leningrad - Riga - Minsk - Moscow. In hot climates and low temperatures, when driving on mountain roads and cobblestone highways, high-speed highways and off-road, the strengths and weaknesses of the prototype vehicle were revealed.

The successful course of testing an already existing original car changed the attitude of the ZiL leaders towards it, turning them from opponents of youth enthusiasm into ardent supporters of the new car. Quickly assessing the merits of the design and the great opportunities that the large-scale production of ZiL-118 opened up for the plant, ZiL director A. G. Krylov, without waiting for the end of the tests, sent a proposal to the State Committee for Automation and Mechanical Engineering of the Council of Ministers of the USSR to assist in allocating the necessary appropriations for mass production organization. However, the government replied that the Seven-Year Plan did not provide for the allocation of the necessary funds for the construction of a new production facility, so it was proposed to postpone its implementation to a later period.

The postponement of the serial production of the ZIL-118, for obvious reasons, could not cause delight among the factory workers, however, the available time reserve was used to complete the full test cycle, improve the design and create new modifications. The attempts of the ZiL management to establish the production of machines of a new family in the amount of 250-300 pieces in the areas of some auxiliary industries were not crowned with success.

In the process of further work and the accumulation of operational experience, the understanding gradually came that the ZIL-118 should be considered not as a passenger car, albeit a multi-seat one, but as a full-fledged bus. This was indicated by the carriage layout, a different placement of passengers, the ratio of their number to the volume occupied, and lower fuel consumption per person. According to the then existing classification according to the transport purpose, "Youth" could be attributed to city and suburban buses, and according to the total number of passengers carried - to buses of small capacity. Among mass-produced buses, ZIL-118, in terms of overall weight and passenger capacity, took an intermediate position between RAFIK and PAZik . However, if in terms of dynamic parameters, ride comfort, smooth running and acceleration, ease of control, only some cars could compete with Yunost - ZIL-111, Chaika and partly GAZ-21 .

Trial operation of "Youth" took place in one of the taxi companies in Moscow. To improve the fit and accommodation of passengers, two seats were dismantled, reducing the capacity to 15 people. The whole complex of the obtained technical and economic characteristics was compared with those of the 9-seat minibus RAF-977D, which is widely used on the route lines of the capital. For the creators of "Youth" this event was of particular importance, because in the conditions of frequent acceleration and deceleration, numerous turns, movement with maximum weight loads, it was possible not only to confirm the declared technical parameters, but also to check the structural strength of the body, the reliability of all systems, fuel efficiency , comfort, serviceability. Despite twice the cost of the bus itself, fuel consumption, the laboriousness of maintenance and repair, due to the increased dimensions, capacity, engine power and design complexity compared to the RAF-977D, the annual economic effect of the ZIL-118 operation exceeded 600 thousand rubles, which at that time was a very serious indicator. And this was not surprising. It turned out that the highest density of passenger flows made the capacity of the Riga car insufficient, and replacing this model with the ZIL-118 would reduce the number of fixed-route taxis on the streets of Moscow by 1317 units, with the same volume of traffic as RAF-977D. And if we add to this lower operating costs than a competitor, higher reliability and durability of the power plant, the presence of a power steering, better conditions for the driver and passengers (interior equipment, ventilation, heating, visibility, less body swaying when driving, etc. . d.), then "Youth" looked like the undisputed favorite.

In the same period, following the decision of the Council of Ministers of the USSR, ZiL, in close cooperation with the institutions of the Ministry of Health and enterprises of the Ministry of Medical Industry, manufactured the ZiL-118 A, a specialized ambulance.

Its peculiarity was that already during the movement, the patient could be provided with such a complex of operational services that were not available on other types of machines of a similar purpose. To do this, the car was equipped with a variety of medical equipment, which essentially turned it into a mobile hospital, and the middle part of the roof, more than two meters long, was made lifting, which allowed doctors to work at full height. Special lighting and conveniently located containers for instruments and oxygen provided an opportunity in case of an urgent need for an operation in a car. The extraordinary smoothness of the ride, excellent driving performance and advanced technical equipment minimized the arrival time of on-call specialists and provided optimal conditions for transporting patients.

A real triumph awaited "Youth" in 1967, when the USSR for the first time decided to participate in the Semaine Internationale du Car - the prestigious "Bus Week", held from 2 to 5 May in Nice. It was a kind of bus salon, bridesmaids organized by the largest travel agencies in Europe. In technical tests, Yunost showed the best results among 64 contestants in all disciplines without exception. For this, the Soviet minibus was awarded the main cup of the Organizing Committee. In the bodywork competition, Yunosti, along with other domestic buses, was awarded the silver medal of the French Bodybuilding Federation. As a result of this success, offers from foreign tourism and transport organizations rained down. However, ZiL could no longer fulfill these requests - by that time, production was finally curtailed.

In 1971, the modernized ZIL-118K (or ZIL-119) "Youth" appeared.

The designer of the updated minibus was Boris Kuznetsov. And again, the production was literally of a single character, and for three years (from 1972 to 1974) not a single car was built. There were several interesting modifications of the minibus, including an ambulance, a mobile television station, a pickup truck, an anti-sabotage special vehicle with a heavy-duty container to eliminate suspicious devices. In addition, for some time one of the cars served as a suitcase with a “nuclear button” - strategic missile launch control equipment was mounted in it. The KGB equipped several vehicles with electronic tracking equipment. Allegedly, one of these cars was constantly on duty in the yards near the American embassy. In total, from 1961 to 1994, 93 Yunost minibuses were manufactured.

1987 ZIL 118K "YUNOST" "Youth" of the second generation in various documents bore the ZIL-118K or ZIL-119 indices, and by 1991 was certified according to the new GOST as ZIL-3207. The production of these buses ended in 1994. ZIL built the last copies as official vehicles for his factory garage. This car first worked in GON, then was assigned to the Moscow City Hall. In the TCP, the mark: “Kremlin-9”. More than 10 years after the end of the service was in a private collection. A unique copy in "native" paint and completely authentic condition. Constantly growing in value, excellent investment. The rarest car. Ready for sale, on the move, inspection - Moscow.

Price: 7,000,000

avito.ru

In contact with

Specifications

Over the long (from 1958 to 1991) years of production of the ZIL-157, the technical characteristics underwent some changes, which was predetermined by technical progress in the automotive industry. And the basic model, produced from 1958 to 1961, differed in the following data (TTX):

| load capacity | 4.5 t - on the highway, 2.5 t - on the ground |

| Gradeability | 28° |

| Mass of the towed trailer | 3.6 t |

| Full mass | 10230 kg |

| Curb weight | 5540 kg |

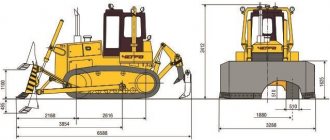

| dimensions | length - 6684 mm; width - 2315 mm; height - 2360 mm (with awning - 2915 mm) |

| Platform dimensions | length - 3570 mm; width - 2090 mm; height - 355 mm |

| loading height | 1388 mm |

| Wheelbase | 4225 mm |

| Rear bogie base | 1120 mm |

| Ground clearance | 310 mm |

| Track | 1755 mm front and 1750 mm rear wheels |

| Turning radius outer | 12 m |

| Max Speed | 65 km/h |

power unit

The modernization of post-war technology concerned primarily the power unit. Trucks of those years did not differ in power and had a lot of shortcomings. The new car received an innovative 4-stroke carburetor gasoline unit for those times. The 157th diesel was not produced on an industrial scale.

With an improved power plant, the ZIL-157 fuel consumption decreased by 7-22% with an increase in productivity (the parameter depends on driving conditions).

The disadvantage associated with overheating was eliminated by installing a radiator with a 6-blade fan. The ventilation scheme has been completely revised, it was made according to the type of closed-loop crankcase. The modified design of the crankshaft oil seals improved the operation of the oil pump. The water pump seals have also been improved.

The installation of a new aluminum alloy head on an inline 6-cylinder block with a displacement of 5.55 liters made it possible to increase the compression ratio to 6.2. The power of the machine was 104 hp. at 2600 rpm, after the next modernization in 1961 - 109 hp The engine ran on A-66 gasoline, and after 1978 - on A-72. Fuel consumption per 100 km averaged 42 liters, but spending depends on the road surface.

Additional characteristics of the power plant:

- torque - 334 Nm;

- cylinder diameter - 101.6 mm;

- ignition order - 1-5-3-6-2-4;

- cooling is liquid.

The ZIL engine did an excellent job with the most difficult tasks, it started up easily even after a long idle time. Problems arose only when working at low temperatures, so special casings came with the machine. Over the years, the problem of maintaining a constant operating temperature was solved, but the heatsinks for the radiator remained in the package.

Transmission

The manual 5-speed gearbox at first provided for a fifth overdrive, but in 1961 it was excluded. The transfer device has been improved: new oil seals and wear-resistant gears have appeared, the possibility of forced activation. Clutch - dry, 1-disk. Transfer ratios of the transfer case: first gear - 2.27, second - 1.16.

Changed the scheme of cardan transmission. An intermediate support for the rear axle cardan appeared on the middle axle. High-strength casings were introduced into the drive axles. The front axle was supplemented with hinges with the same angular velocities. The razdatka had 2 downshifts. The driver has the opportunity to turn off the front axle.

Dimensions and wheels

Related industries also worked on the development of a new car. Tire manufacturers commissioned to develop special tires that allow movement with a temporarily reduced air pressure in them. The designers had to revise the layout of the new all-terrain vehicle. Instead of the 10 wheels that the ZIS-151 had (plus 2 spare ones), 6 were installed on the new model with a tire size of 12.0018 and an air pressure of 3.0-0.5 kgf / cm².

The tire was distinguished by increased elasticity, tk. the number of cord layers was reduced to 8, and soft rubber was used for the inner layers.

To increase off-road patency (swamps, sand, etc.), the driver remotely reduced tire pressure using a centralized system. The car continued to move at low speed (10 km/h). The movement of the truck could continue in the event of damage to a single tire.

The design solution made it possible to eliminate the wheel holders located behind the cab, for 1 spare there was a place under the platform. The opportunity to move the platform to the cab changed the dimensions of the truck (the frame became shorter by 250 mm, the overall length by 330 mm), the weight decreased by 100 kg. The distribution of mass along the axes has also improved.

Modifications

On the base 157th ZIL, more than 10 variants were produced under the indices:

- B - truck tractor;

- K - basic version improved in 1961;

- KV - truck tractor, developed in 1961;

- G - option with the use of shielded electrical equipment for protection against radio interference and radar detection;

- KG - modification of 1961 with the use of shielded electrical equipment based on variant K;

- KD - a variant from the Ural plant, which received an improved carburetor, appeared in 1978;

- KDV - truck tractor 1978;

- E - special version equipped with 2 fuel tanks of 150 l;

- E - transport for delivery to the countries of the Warsaw Pact;

- Yu - a car with a modified cooling system and a larger radiator for operation in a tropical climate.

ZIL-157 KDM is an experimental flatbed truck of 1984 with a ZIL-157KD engine and transmission, a cab from ZIL-130 and ZIL-131, a frame and a platform from ZIL-131. But prototypes are not limited to the ZIL-157KDM, for example, in 1962, the ZIL-157KV1 was manufactured - a truck tractor for working with semi-trailers.

dump truck

The dumping installations of the Mytishchi plant decided to adapt a dump truck on the ZIL-157KD chassis. The prototype ZIL-MMZ-4510 was built in 1988. It received a metal platform with a dump mechanism and a hydraulic pump. The tests revealed a number of problems, as a result, dump trucks were produced in a small batch for army needs.

Timber carrier

Serially timber carrier was not produced. However, for the carrying capacity of the ZIL-157, it has found wide application among loggers. The truck is hardy, can overcome swampy areas and terrain with difficult terrain, conscientiously dragging round timber from clearings.

Firefighter

The ZIL hose fire engine was named AR-2. She has an enlarged cabin for the fire brigade and wide rear doors. The fire truck is equipped with a 4.5 ton water tank and a telescopic ladder. Can work in the most hard-to-reach places.

Gasoline tanker

ATZ-3-157 is a fuel tanker, which began to be produced back in 1958. In 1959, an army water and oil tanker VMZ-ZIL-157 appeared, in which one tanker was designed for 1400 liters of water, the other for 700 liters of oil. ATsMM-4-157K is a fuel and oil tanker built in 1962 with a capacity of 250 liters of technical oil.

Bus

On the basis of the chassis of the 157th model, for the needs of the Western Group of Forces in Germany, a cabover staff bus was produced.

Child of the Soviet atomBuses "Tajikistan" and ChAZ manufactured by JV "Khujand-ZIL"

Denis Dementiev, photo from the archive of the author and the Khujand-ZIL joint venture

January 1945. Moscow. Kremlin. “When the Americans equip their Air Force with atomic bombs in five years, they will want to dictate their terms to us. By this time we should have our atomic bomb. Comrade Kurchatov assured the Politburo that in the presence of uranium this period is real ... ”- this is how Joseph Stalin began his speech, addressing the young NKVD officer B.N. Chirkov, who soon headed the construction of a top-secret plant for the extraction and processing of uranium ore in Central Asia.

In May 1945, the USSR Defense Committee adopted a resolution on the creation of the so-called Combine No. 6 in the north of Tajikistan. Impressive funds for those times were allocated for its construction. It was built in an extremely short time by prisoners of the Gulag: former captured Soviet officers and Germans evicted during the war from the Volga region. The plant, located not far from Leninabad, became the first mining enterprise of the nuclear industry in the Soviet Union.

With the construction of the plant, the infrastructure also developed. In a short time, the modern city of Chkalovsk, the nuclear science city of the country, which received the code name Leninabad 40, grew up. Ancillary industries also expanded in the city to meet the needs of the mining and processing plant (GOK). So, on the basis of the central car repair shops (TsARM), organized at the plant at the end of 1945, an auto repair shop was formed. After the commissioning of new sites in 1953, it was reorganized into the Chkalovsky Automobile Repair Plant (enterprise p / box G-4264), which provided repairs for automotive and tractor equipment that worked at the mining and processing plant and in local mining departments. In particular, the plant mastered the overhaul of GAZ-MM, GAZ-51, ZIS-150 vehicles, S-80, S-100 tractors and E-302 excavators. They also repaired Lend-Lease equipment in large quantities, which after the war worked on uranium mining: Dodge, Willys, Studebaker ...

In March 1958, the USSR Ministry of Medium Machine Building, which oversaw the nuclear industry, including the activities of the Leninabad Mining and Chemical Combine (LGCC), the former GOK, ordered mass production of buses to transport workers to the ministry's facilities. The task was entrusted to Chkalovsky ARZ, which already had some experience in creating wooden frames for the repair of ZIS-16 buses.

The development of new products began with the choice of a product that was to be assembled. They became KAG3, produced by the Kaunas car repair plant No. 3 - a bus with a wood-metal wagon-type body based on the GAZ-51 chassis, simple in design and well fitting into small-scale production technologies. An agreement was concluded between the plants to provide working documentation, and in August 1958 a large group of Chkalov engineers arrived in Kaunas, where they studied bus assembly technology. From the Baltic States to Chkalovsk they brought not only all the technical documentation, but also a complete set of body parts, according to which templates, samples and equipment were quickly prepared at the plant.

The first bus, assembled from Kaunas kits in May 1959, received the designation "Tajikistan-1". During the year, he was tested and in the fall he was sent to Moscow for a show. In 1960, the first serial 112 passenger cars were manufactured at the plant. We must pay tribute to the employees of the enterprise, who in such a short time were able to “raise” a new direction for themselves. Although, to be honest, the initial steps in mastering the production of machine-building products in Chkalovsk did not immediately give a perfected technology for the mass production of wooden frames. Put together with a lot of screws, nails and wood glue, they were an eerie sight. According to the recollections of the plant workers, among the tools used by the manufacturers of wooden frame parts, the ax stood out in particular!!! But experience comes with time, and a few years later the Chkalovsky ArZ produced 150-200 passenger cars a year.

In addition to buses, they gradually began to master the production of other products, in particular scarce trailers and semi-trailers. The first in 1961 was a two-axle trailer with two-sided side unloading ASP-3, and a few years later two-axle semi-trailers PPS-14 and PPS-20 appeared. On the basis of the latter, tanks PC-9.5 were also produced for the transportation of caustic liquids and acids, which were used in the processing of uranium ore and rare earth metals. Since the beginning of the 60s, van bodies on the GAZ chassis have become another direction of the plant's production activity: XB-70 for the delivery of bread and M-61 for the transportation of meat products.

In 1966, on the GAZ-6601 chassis, a special vehicle was developed for the militarized mine rescue units (VGSCh) of the Minsredmash and Mintsvetmet of the USSR systems. It was intended to deliver the task force of rescuers to the accident site; it had a van-type GM-01 body with a passenger compartment equipped with personal protective equipment. Initially, the VGSCh car body had a wooden frame, but in 1968 its design was significantly improved: the body became all-metal, the interior layout changed. Since 1974, on the basis of the VGSCH car, a passenger shift bus with a GM-02 body has also been produced in small batches. In the 80s, both cars received their own indices: rotational - AS-3901; mountain rescue - AS-3902. They were produced until 1992.

But let's get back to the buses... The Tajikistan-1 model stayed in production with minor changes until 1976, and its modular bodies (fully assembled, but without chassis) were supplied to the enterprises of the ministry until 1978. In 1962, the modernized "Tajikistan" received the index "T-1A": sliding windows appeared in the windows, an additional heater and decorative body elements. But all this did not save the outdated design, and in 1968 a group of engineers from the factory design bureau began to develop a new bus based on the GAZ-52-01 chassis with an all-metal body. A year later, the first prototype of "Tajikistan-2" was presented in Moscow. According to the comments of the commission, the product was redesigned. In 1970, the first 24 serial T-2 buses on the GAZ-53A chassis saw the light. During the production process, the design was repeatedly subjected to changes: in 1973, after another modernization of the appearance, the bus received the T-2A index, and in 1975 - T-2B. And on April 4, 1975, the 1000th bus of the second series was produced.

The operation of buses "Tajikistan" in the harsh conditions of the Urals, Siberia and Central Asia, where they carried teams of workers on quarry off-road, revealed a number of significant shortcomings in their design. First of all, it was about the low endurance and traction characteristics of the base chassis. Therefore, in 1974, it was decided to use the ZIL-130 chassis, which had a more powerful engine and an efficient braking system. For the purpose of design continuity, prototypes of the T-3 and T-4 on the new chassis received a body that was almost completely unified with the previous model "Tajikistan-2B". However, tests at the Dmitrov test site showed that it was necessary to develop a new body under the ZIL-130 chassis. Work on the creation of the model "Tajikistan-5" lasted less than a year: they worked hard, 14 hours a day. As a result, in 1975, the first two samples of the new bus were presented to the NAMI test site. In general, the design turned out to be successful, and the following year, the Tajikistan-5, modified for mass production, again went to Dmitrov ... Based on the results of comprehensive tests, the bus was recognized as fit for serial production, and in 1976 the plant managed to produce the first batch of 19 cars.

For several years, "Tajikistan-5" was produced in small batches in parallel with T2B. At this time, the buses were gradually modernized, getting rid of the "childhood sores" that inevitably surfaced during operation. In 1978, buses received a wider three-leaf (!) passenger door instead of a double-leaf and new front lighting. Already on August 1, 1980, the 1000th T-5 bus was produced, completely replacing the outdated model on the assembly line. In 1982, the buses were named according to the new industry standard "Tajikistan-3205", but the name change did not entail changes in the design of the bus. An interesting fact: the PAZ bus also received the index "3205". However, this did not prevent him from becoming a "double", since "Tajikistan" did not have an officially assigned index through the Ministry of Automotive Industry.

In 1986, to eliminate the consequences of the accident at the Chernobyl nuclear power plant, on the instructions of the Minsredmash, several batches of 20-seat buses "Tajikistan" were urgently built with a forced air ventilation system and lead panels in the body sheathing, for which they received the nickname "pig buses". More than fifty of these cars with carefully sealed skin seams had a different design of passenger seats, in which you had to sit almost on the floor itself. Realizing the emergency of the situation, the plant staff worked around the clock. Only 15 days passed from the moment the order was received to the shipment of the first batch of 10 "pig-buses": in June 1986, the liquidators who built the sarcophagus were already driving them ...

Freed from military orders, in the late 1980s. at the plant, which by that time had become authoritative among machine-building enterprises, they began to think about creating a new bus model to replace the T-3205. The latter, although it enjoyed well-deserved respect in the fleet, was morally obsolete. For this reason, in 1990, by order of the Minsredmash, the Lviv VKEI of the bus industry began developing a new series of base buses for the Chkalovsky ArZ: with a wheelbase of 3800 and 4500 mm. In May 1991, one prototype "Tajikistan-4209" was assembled in the experimental workshop of the VKEI on a short-wheelbase chassis with a ZIL-645 diesel engine, but in 1992 the contract was terminated ... The second, long-wheelbase version of "Tajikistan-42091" remained in the form bare frame to rot on the territory of the ARP.

The hard times of the post-perestroika process in the USSR painfully affected the economy of the Central Asian region. Socio-political upheavals also affected the Chkalovsky plant. The severing of long-established ties with suppliers and customers has affected the economic stability of the once-thriving secret enterprise. In order to survive in these conditions, in 1991, at the suggestion of the LGKH management, on the basis of the Chkalovsky ARZ, renamed the Chkalovsky Bus Plant, the Khujand-ZIL joint venture was created. AMO ZIL, having 49% in the authorized capital of the joint venture, under the contract undertook to supply the Republic of Tajikistan with chassis for the production of passenger cars on account of contributions; he was also the main dealer of ChAZ for the sale of buses "Tajikistan" in Russia.

In 1993, the plant made a second attempt to create a new bus. Together with the designers of ZIL and AZLK, a project was developed for two basic models: "3220" - a short-wheelbase gasoline and "4214" - a long-wheelbase diesel. The first assembled CHAZ-3220 was presented to the general public at the Moscow Motorshow-93. Over the next year, three more examples of the 3220 were built, one of them with a diesel engine. However, a detailed study of the manufactured samples revealed a number of significant miscalculations in the design. The possibilities of existing production were not taken into account. The bus needed to be seriously improved, but there were not enough financial assets for this - the project was frozen until better times.

1994 was marked by a desperate attempt to organize the assembly of buses of the 3205 model in Russia. This could solve two important problems at once: the difficulty of supplying chassis and other components from Russia to Tajikistan, and the problem of sending ready-made buses back, where the main consumers of ChAZ products were concentrated. Through the mediation of AMO ZIL, an agreement was concluded with the joint venture "Rodnikovskoe management of enterprises" (Rodniki, Ivanovo region), on the basis of which it was planned to deploy the assembly of buses from Tajik car kits. For this purpose, several specialists arrived from Chkalovsk, who brought complete (!) Technical documentation and a finished frame of the bus body. However, this combination failed miserably: the then management of the JV "RUP" decided, bypassing ChAZ, to independently establish the production of buses using Chkalovsky drawings. So the twin of "Tajikistan" was born - the bus "Rodnik-3230".

From that moment on, things at the Chkalovsky plant went from bad to worse - political unrest in Tajikistan forced many engineering workers to leave, and the plant was left almost without qualified personnel.

In addition, due to lack of demand, the company assembled 5-10 cars a year, which barely met the needs of the republic itself. In order to raise interest in Tajik buses in Russia, the plant tried to modernize the existing model. In the period from 1994 to 1997, the buses received a new chassis, the brake system was changed, and a more attractive color scheme was introduced. The updated ChAZ family of buses included the following models: "3223" - on the ZIL-431410 chassis; "32231" - on the ZIL-433362 chassis; and "32232" - on the ZIL-433102 chassis (later ZIL-432912). Brief technical characteristics of buses produced by JV "Khujand-ZIL"

| Model | CHAZ- -3223 | CHAZ- -32232 | CHAZ- -32231 | CHAZ- -322311 | CHAZ- -322312—01 | CHAZ- -322312 | |

| Base Chassis | ZIL-431410 | ZIL-432912 | ZIL-433362 | ||||

| Number of passenger seats | 24 | 25 | 24 | 24 | 25 | 27 | |

| Total capacity, pers. | 42 | 41 | |||||

| Overall dimensions, mm | 7345x2500x2975 | 7345x2500x3088 | |||||

| Ground clearance, mm | 230 | ||||||

| Weight, kg: - full - equipped | 8670 5730 | 8890 5950 | 8780 5840 | ||||

| Overhang angle, degrees: – rear – front | 18 38 | 18 36 | 16 36 | ||||

| Engine | ZIL-508.10 | ZIL-0550 | ZIL-508.10 | ||||

| Fuel consumption, l/100 km* | 26,5 | 22,5 | 26,5 | 29 | |||

| Maximum speed, km/h | 90 | ||||||

*Control data at 60 km/h.

In 1999, in order to obtain the Russian TS Type Approval, the plant began a deep modernization of its buses: the transitional models CHAZ-322311 received a higher roof, smaller side emergency windows. Two years later, the design of the rear part of the body was completely changed (it was made almost vertical), the passenger door became double-leaf, and all side windows were unified to one size. New buses received the index "322312". On their basis, an urban two-door version of CHAZ-322312-01 (CHAZ-32231A) was created specifically for the Russian market. But it, unfortunately, was released only in a circulation of a few copies. The plant also produced custom-made buses in various configurations: ritual, enhanced comfort, armored, passenger-and-freight, with an isothermal body, and others.

However, ChAZ buses were not in demand in Russia: many consumers were still repelled by the remoteness of the manufacturer, although the use of the ZIL base chassis made it possible to easily service these vehicles. And the time-tested frame structure was the best suited for the difficult conditions of Russian off-road. The only pity is that all these advantages of Tajik buses were ignored, since little is known about them in Russia.

Now the Chkalovsky bus plant does not live up to its name. The enterprise lives by overhauling trolleybuses and producing trailers. The production of buses has practically stopped - 3-5 buses leave the factory a year. However, according to the management, the enterprise can reach the design annual capacity of 500 buses (!) at any moment… if there are orders. It is a shame to see the fact that the leadership of Tajikistan is not trying to save the only enterprise of the national automobile industry. And while such a conflict develops, the plant can only rely on the Russian consumer ...

The author thanks the Kasymovs Sayfutdin Kasymovich and Marat Sayfutdinovich, as well as Khlestkin Viktor and Elizarov Vladimir for their help in preparing this material.

Reviews and prices

Serial production has long been completed. On sale you can now find only equipment from the 1980s or 90s. The price of the models is from 40,000 rubles.

Vladimir, 55 years old: “From the time of service in the army, the hands of the cleaver ZIL-157 are remembered, its characteristics for those years were the best. In our unit there was another technique, it could not be compared either in power or in cross-country ability.

Vadim, 36 years old: “I heard about the car from my father and his driver friends. They worked in the Far North, in Kazakhstan, at large construction sites. The car in conversation is called Zakhar. As a child, I thought that this was such a brand of truck, and when I grew up, I realized that they call it that out of respect, and all the drivers of the country.”