How to switch gears Ural gearbox

The gearbox device installed on some Ural models includes the following elements: The gears rotate freely when neutral is engaged, at which time all clutches and synchronizers are in the open position.

When the driver starts to squeeze the clutch mechanism and switches the handle to some other gear, then a special fork device begins to move the clutch into the engagement position with the corresponding pair on the end of the gear.

The gear mechanism is rigidly fixed to the shaft and stops scrolling on it.

Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique.

If you want to know how to solve your particular problem, please use the online consultant form on the right or call the numbers listed on the site. It's fast and free!

- Gearbox and transfer box control

- Ural gearshift scheme

- How to shift gears on a motorcycle. In the Urals, gear shifting

- Review and repair of checkpoint Ural 4320

- Gear shifting on a motorcycle

- How to switch speeds

- The principle of operation and troubleshooting in the Ural checkpoint device

- How to switch gears Ural gearbox

WATCH A VIDEO ON THE TOPIC: Gearbox on a KAMAZ car (shift diagram) for subscribers

Gearbox and transfer box control

Ural is a popular truck that is great for cross-country operation in forestry.

This is facilitated by high ground clearance, a powerful motor. This car is equipped with YaMZ diesel engines. Power can exceed horsepower.

The gearshift scheme is well-designed by the manufacturer of this equipment. Approximately 30 liters of fuel are spent per km. If this indicator has increased, it is necessary to conduct a premature diagnosis of the automotive system.

A winch in the Urals is necessary for self-pulling vehicles or pulling other vehicles. Maintenance of the winch consists in a direct check, tightening of all fasteners.

Ural trucks are valued for their high power characteristics, excellent load capacity, and driving dynamics.

In many ways, the installed gearbox affects the performance of this vehicle. This device affects the power set. A five-speed gearbox is installed on the Urals.

It has a long service life, perfectly tolerates the loads that fall on it. The gearbox housing Ural is attached to the clutch housing. A manual gearbox on a Ural car has fixed shaft axles. The upper crankcase cover is equipped with a gearshift mechanism.

The transmission system includes lockable cross-axle and center differentials. On the truck there is a box of dependent power take-off or KZOM. It should be noted the presence of a transfer case in the Urals. It is a 2-stage one, it affects fuel consumption for each kilometer traveled.

This box is securely fixed to the frame with several special rubber pads. The transfer box Ural is an additional gearbox.

It provides a stable movement of the machine at low speed. The installed Ural power take-off is single-stage. It is necessary to drive auxiliary units.

In order for the speed box to serve for many years, the owner of the Ural car must service it with high quality. Caring for the transmission system is expressed in the following: replacement of used oil; replacement of worn components that relate to the gearbox.

We list the main reasons why the box breaks down:

The need to diagnose the Ural gearbox arises if it becomes difficult to shift gears, increased noise from the transmission side has begun to be noted. If a breakdown of the gear teeth occurred in the Ural gearbox, then due to this, a characteristic noise from the side of the box will be noted during movement on the road.

However, the appearance of noise can be directly related to the fact that the gearbox has a low amount of fuel. In most cases, oil leakage is the result of natural wear of rubber seals.

These consumables are not restored, but replaced with new ones. At the same time, the price for them remains at an affordable level. When filling in new gear oil, the prescribed requirements must be followed.

In the Urals, you can check the level of available oil using the existing pointer. It is necessary to check the condition of the transfer case if difficult gear shifting has begun to be noted.

As a rule, this occurs due to the fact that notches have appeared on the couplings.

Oil should be added to the transfer case through the top hatch. For a transfer case, about 3 is required. For a speed box, it is recommended to use TSpK mineral transmission oil. This fuel is used by many heavy vehicles. The viscosity category for TSpK is as follows - 80W The use of high-quality oil helps to reduce wear of rubbing parts.

Since URAL machines are subject to heavy loads, you need to pay attention to the clutch mechanism. In some cases, if it is damaged, gears may not turn on well.

If it is difficult to change gears, first of all, you should pay attention to the integrity of the rods, synchronizers. Repair and restoration work is best left to experienced professionals. It is forbidden to continue to operate the truck, where there are worn-out engine or transmission mechanisms, urgent repairs are necessary.

The box must be completely sealed. A number of deformed parts can be restored by using methods such as welding, melting. Professional gearbox repair requires the appropriate equipment. Repair of checkpoints in the Urals must be carried out in a timely manner. 1 Components of the transmission system 2 Characteristics of gearbox failures.

Gearbox diagram. Power take-off. Gearbox power line Gearshift mechanism. Article rating:.

Ural gearshift scheme

Motorcycle Ural MK. Motorcycle ural wolf. Motorcycle Ural T. Motorcycle Ural M Page 1 of 1 1. Awards: 0. Reputation: 0 Status: Offline.

Features of the gearbox and power take-off - stable movement of the machine at low speed.

Beginners who are just learning the basics of driving and handling a motorcycle look with admiration at how motorcyclists skillfully and silently shift gears on a motorcycle.

And they have an irresistible desire to learn the same impeccable technique for managing their vehicles. But in vain they think that it is so difficult. It's easy to learn. Most motorcycles are equipped with a sequential gearbox.

Therefore, the basic principles of all actions are similar. The first of these means that you need to shift into a higher gear.

Review and repair of checkpoint Ural 4320

Good afternoon, gentlemen, oppositionists, maybe I'm asking a very stupid question, but nevertheless - how to switch gears in the Urals, describe the process itself. Thanks in advance. Already about gear shifting questions have gone. You'd better find someone with experience.

Depending on the car model, on the new KamAZ, the control scheme and the location of the transmission gears may differ.

Most motorcycles are equipped with a sequential gearbox. Therefore, the basic principles of all actions are similar. The first of these means that you need to shift into a higher gear.

To do this, you engage first gear, and thus increase the speed of the motorcycle, and then gradually shift to the next gear in the following sequence:

This is done when it is necessary to increase the power of the rear wheel, for example, going uphill.

How to switch speeds

The gears in the gearbox are shifted using the gear lever located to the right of the driver's seat. Press the clutch pedal sharply and to the end. Change gears at minimum idle speed.

Start driving only from first gear to avoid premature failure of the clutch. For gearboxes of models , , , Gearshift according to the diagram, see Gearshift diagram I.

Gearshift scheme I on a car with a gearbox of models, without a divider, this is not provided, and then press and after a short delay of 1s release the clutch pedal - the gear will turn on automatically.

Gear shifting on a motorcycle. Tips for shifting gears on a motorcycle; We shift gears on a motorcycle correctly; Speeds.

Ural is a popular truck that is great for cross-country operation in forestry. This is facilitated by high ground clearance, a powerful engine. This car is equipped with YaMZ diesel engines.

Ural gearshift scheme which may be different depending on the model of the car brand Ural.

If we consider a Ural brand car, or Ural with their modifications, then we will see that a YaMZ U gearbox is installed there. It is three-way and has five gears forward and one reverse.

Gear transmission installed in the box shifts the first gear and reverse. The remaining gears, namely second, third, fourth and fifth are synchronized.

Repair and maintenance of gearbox Ural 4320

Checkpoint URAL 4320

The gear box performs the function of transmitting engine power to the drive axles.

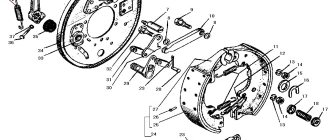

Gearbox device Ural 4320

The gearbox of the Ural car has five forward gears and one reverse gear.

It consists of the following elements:

- Clutch part. It provides separation of the power unit and transmission. This unit allows you to switch speeds without reducing engine speed.

- Gears and shafts. The box has a drive, intermediate and secondary shafts.

- Synchronizer. It ensures smooth and silent operation of the mechanism. When switching speeds, synchronizers contribute to the smooth engagement of the clutch and the corresponding end part of the gear.

Synchronizer URAL 4320

At neutral speed, the gears rotate freely. When the speed driver is turned on, the gear mechanism is fixed with the shaft. The clutch transmits rotational motion and traction.

The gearbox is controlled by means of a handle. It moves sliders with forks that move the synchronizers at a given speed.

To prevent dirt and dust from entering the gearbox through the gearshift lever, there is a rubber protective cover on the support.

Output shaft URAL 4320 The bearings are closed with covers using sealing gaskets. In the upper part of the cover there is a hole for supplying oil from the accumulator. The axis of the reverse gear block is pressed into the right wall of the crankcase. An oil accumulator is located inside the crankcase of the box. When the gears rotate, the oil is thrown into the accumulator and through the channel gets to the rear bearing.

The inclusion of two gears at the same time prevents a ball-type lock located on the box cover. Also on the top cover is a cut-type fuse to prevent accidental activation of the reverse speed.

Change of oil

The optimal oil volume for the Ural 4320 gearbox is 3.5-4 liters. Oil is poured into the hole located on the right side of the crankcase. The plug has a level indicator. A baffle is located inside the crankcase, so the oil is drained from two drain holes. A magnet is built into the front plug to trap metal dust.

To drain the oil, the side plug is first unscrewed, and then the bottom plug. When changing the oil, the magnet on the cork is cleaned of metal particles. The end of the oil drain occurs when the jet changes into a drip. On a Ural 5557 car, in order to gain access to the checkpoint, the cab floor cover is removed.

The main faults of the checkpoint and how to eliminate them

It is important to know that the repair of the Ural checkpoint should be carried out by a specialist with the necessary skills and knowledge.

Checkpoint URAL 4320

- Extraneous sound during the operation of the unit. In this case, it is recommended to inspect, diagnose the unit. If any damaged parts are found, replace them with new ones and, if necessary, adjust the operation of the mechanism.

- Free movement of shafts along the axis. With such a malfunction, it is necessary to replace the broken shaft bearings with new URAL spare parts, as well as install high-quality parts that fix the bearings.

- Unstable operation of the box. The cause of the malfunction may be the wear of the bushings of the reverse shaft axis. The problem is eliminated by replacing worn parts with new parts.

- Incomplete engagement of the clutch. It is worth inspecting the clutch mechanism for breakdowns and defects, as well as checking the lubrication level. Damaged items are exchanged for serviceable parts.

- Stiff movement of fork rods. The malfunction most often occurs due to damage to the blocking crackers. Defective parts are replaced with new ones.

- Spontaneous shutdown of speed. Adjusting the gaps between the valves, replacing the synchronizer rings, installing new springs and tightening the fasteners will eliminate the problems of turning off the speed.

- Indistinct speed switching. The malfunction is eliminated by inspecting the main components for wear, as well as replacing the clutch and gear.

Features of towing a Ural car with an idle engine

URAL 4320

For long-term towing, in order to preserve the bearings of the output shaft of the gearbox, the intermediate cardan is dismantled with an idle motor. If it is possible to dismantle the shaft, the towing speed should not exceed 40 km / h.

Checkpoint maintenance

Checkpoint URAL 4320

Maintenance of the gearbox consists in checking the fastening of the unit to the car engine. Along with this, it is necessary to periodically check the condition of the suspension, the level and quality of the oil in the mechanism.

The gearbox is flushed with special flushing oils. To do this, flushing is poured into the crankcase of the box and the engine starts for 7 minutes with the neutral speed turned on. After that, the flushing oil is drained and new is poured.

It is forbidden to use diesel fuel, kerosene to flush the gearbox. Their use leads to failure of the oil pump. When installing a gearbox on a car, it is necessary to fill the pump with oil in advance to ensure that fluid is sucked into the system when the engine is started.

It is worth remembering that the dismantling and installation of new Ural spare parts is carried out only with the engine turned off. When starting the engine at temperatures below 30 degrees Celsius, it is recommended to warm up the gearbox. If the car is not being used during frost, it is worth draining the oil from the box.

When starting the engine in the cold season, the oil is filled only in a heated state.

How to switch speed on a car Ural scheme

Ural is a popular truck that is great for cross-country operation in forestry. This is facilitated by high ground clearance, a powerful engine.

This car is equipped with YaMZ diesel engines. Power can exceed horsepower. The gearshift scheme is well-designed by the manufacturer of this equipment.

Approximately 30 liters of fuel are spent per km.

RELATED VIDEO: ABOUT KAMAZ checkpoint. SCHEME, DOUBLE SPRING AND REGASING.

Dear readers! Our articles talk about typical ways to resolve legal issues, but each case is unique.

If you want to know how to solve your particular problem, please use the online consultant form on the right or call the numbers listed on the site. It's fast and free!

- Review and repair of checkpoint Ural 4320

- The principle of operation and troubleshooting in the Ural checkpoint device

- How to switch gears Ural gearbox

- How to shift gears on a motorcycle. In the Urals, gear shifting

- Ural gearshift scheme

- Gearbox and transfer box control

The principle of operation and troubleshooting in the Ural checkpoint device

Beginners who are just learning the basics of driving and handling a motorcycle look with admiration at how motorcyclists skillfully and silently shift gears on a motorcycle. And they have an irresistible desire to learn the same impeccable technique for managing their vehicles. But in vain they think that it is so difficult.

The gears in the gearbox are shifted using the gear lever located to the right of the driver's seat. Press the clutch pedal sharply and to the end. Change gears at minimum idle speed.

Ural gearshift scheme which may be different depending on the model of the car brand Ural. If we consider a Ural brand car, or Ural with their modifications, then we will see that a YaMZ U gearbox is installed there. It is three-way and has five gears forward and one reverse. Gear transmission installed in the box shifts the first gear and reverse.

How to switch gears Ural gearbox

The gearbox device installed on some Ural models includes the following elements: The gears rotate freely when neutral is engaged, at which time all clutches and synchronizers are in the open position.

When the driver starts to squeeze the clutch mechanism and switches the handle to some other gear, then a special fork device begins to move the clutch into the engagement position with the corresponding pair on the end of the gear. The gear mechanism is rigidly fixed to the shaft and stops scrolling on it.

The clutch in this position contributes to the transmission of rotational motion and traction. While the vehicle is moving, the gearbox is actuated by the gear lever. It moves sliders equipped with forks, which begin to move the synchronizers at the required speed.

There is a color shift scheme in the Ural user manual. It is necessary to fill in oil in accordance with the user's instructions. For Ural cars, the sufficient level of oil fluid is 3, l.

How to shift gears on a motorcycle. In the Urals, gear shifting

Depending on the car model, on the new KamAZ, the control scheme and the location of the transmission gears may differ. Domestic trucks can be equipped with two types of gearboxes.

The difference is that some transmissions have five gears, while others have ten.

These models are called 14 and 5 speed transmissions are usually fitted to cars that are used as individual cars.

.

The principle of operation and troubleshooting in the Ural checkpoint device

The Ural gearbox is a device in the vehicle system that is responsible for transmitting power.

How the checkpoint works

The KPP-141 device installed on some Ural models includes the following elements:

- Coupling mechanism. It helps to temporarily separate the engine and transmission. This allows you to shift gears without reducing the speed of the power unit.

- Driven gears and shafts. The drive, intermediate and secondary shafts are installed here.

- Synchronizer. It ensures silent operation of the mechanism and equalization of gear speeds.

The gears rotate freely when neutral is engaged, at which time all clutches and synchronizers are in the open position.

When the driver starts to squeeze the clutch mechanism and switches the handle to some other gear, then a special fork device begins to move the clutch into the engagement position with the corresponding pair on the end of the gear.

The gear mechanism is rigidly fixed to the shaft and stops scrolling on it. The clutch in this position contributes to the transmission of rotational motion and traction.

While the vehicle is moving, the gearbox is actuated by the gear lever. It moves sliders equipped with forks, which begin to move the synchronizers at the required speed. There is a color shift scheme in the Ural user manual.

Gear ratios of the Ural box:

- the first stage - 5.26;

- the second stage - 2.90;

- third stage - 1.52;

- fourth stage - 1.00;

- fifth step - 0.664;

- reverse - 5.48.

Faults and repairs

The main malfunctions and repair of the box:

- Extraneous noise in the mechanism. In this case, it is recommended to conduct an external inspection of the system and replace damaged and worn parts.

- The shafts move along the axis. It is necessary to replace the parts that fix the bearing, or replace the failed bearings.

- Unstable operation of the checkpoint. This problem may be due to wear on the bushings of the reverse spline shaft. Replace damaged mechanisms.

- Clutch does not fully engage. In this case, it is recommended to carry out an external inspection of the coupling mechanism for damage and defects, check the level of the lubricant in the system and replace the damaged elements.

- The stems of the forks move hard. This malfunction can be caused by damage to the blocking crackers, synchronizers. It is necessary to replace the mechanisms with new ones.

- If the gearbox spontaneously turns off, it is necessary to adjust the gap between the valves, replace the worn synchronizer rings, install new springs, tighten the fasteners.

- In case of fuzzy switching, it is necessary to remove the cover of the fixing device and inspect the main components for wear, replace the clutch and gears.

Repair of the gearbox is carried out only with the power unit turned off.

How to adjust

Gearbox adjustment is carried out as follows:

- Install the vehicle on a special platform.

- Using a jack, slightly raise the front of the car body and fix it in this position.

- On the transmission control rod, loosen the fixing nuts of the clamp coupling bolt. The nut is loosened by 4.5 turns.

- Using a screwdriver, expand the grooves at the end of the traction device and the clamp.

- Move the stem to the neutral position.

- Unscrew special fasteners.

- Remove the cover from the gearbox from the control handle. The cover is lowered to the very bottom of the case, and the handle itself is set in a vertical position with the end up.

- Loosen the clamp mechanism.

- Engage reverse gear when the power unit is not running.

- The prepared template is installed in the lining window, as well as the reverse gear lock bracket.

- The stop of the axial mechanism is inserted into the groove of the template and pressed against the system body.

- Set the required gap between the elements. Tighten fasteners and clamp.

- Start the engine and check the serviceability of the adjusted gearbox.

How much oil to fill

It is necessary to fill in oil in accordance with the user's instructions. For Ural cars, a sufficient level of oil fluid is 3.5-4 liters.

How to remove and disassemble

In order to dismantle and disassemble the gearbox, you must:

- Place the vehicle on a lifting device or a viewing hole.

- Remove the batteries, air filter element and mudguards. They are located at the bottom of the engine compartment, in the center and along the edges.

- Remove the front suspension cross member and the front drive wheels.

- Drain the transmission fluid from the box.

- Disconnect the wires of the sensor responsible for the speed indicators. To do this, pry the wires with a screwdriver and carefully remove the spring locking device.

- Remove the vehicle reverse switch.

- Remove the engine harness holder.

- Remove the mounting bolts from the gearbox and the hydraulic clutch release bracket.

- Remove the bolts from the working cylindrical block, clutch housing, booster.

- Dismantle the crankcase.

- Install the support under the dismantled box.

- Disconnect the front and rear supports from the bracket.

- Move gearbox back and place on a hard surface.

- Unscrew fasteners and disassemble.

How to assemble and install

Box assembly procedure:

- compress the bearing;

- insert a chisel into the gap between the end part of the inner race of the bearing and the differential box;

- install the bearing and the axial mechanism of the satellites;

- insert the support ring into place;

- install drive gears and differential box;

- tighten fasteners;

- put the synchronizer ring;

- install the sliding sleeve and the retaining ring of the hub of the synchronizing device;

- install the driven gear and thrust washer;

- adjust the clearance between the front bearing ring and the drive type gear.

The installation of the gearbox in the Urals is carried out as follows:

- install a support under the checkpoint;

- fasteners are screwed to the block of cylindrical elements;

- install the left engine mount with 4 fixing nuts;

- put the rear support, attach it to the body;

- connect the gearbox bracket and the front motor support;

- install the clutch housing, connect the cables with brackets;

- connect the lever cables and support washers;

- install the exhaust gas converter, put the cover in place;

- connect the amplifier to the cylinder block;

- screw the holder of the motor harness;

- install a latch, shoe, spring mechanism;

- connect the front drive wheels, mudguards, air filter and batteries.

How much is the box

The average cost of a box in the Urals is 80,000 rubles.

Source: https://SpecMahina.ru/ural/kpp.html

Review and repair of checkpoint Ural 4320

Ural 4320 is a popular truck that is great for cross-country operation in forestry. This is facilitated by high ground clearance, a powerful motor. This car is equipped with YaMZ diesel engines.

Power can exceed 300 horsepower. The gearshift scheme is well-designed by the manufacturer of this equipment. Approximately 30 liters of fuel are spent per 100 km.

If this indicator has increased, it is necessary to conduct a premature diagnosis of the automotive system.

The winch on the Ural-4320 is necessary for self-pulling vehicles or pulling other vehicles. Maintenance of the winch consists in a direct check, tightening of all fasteners.

Components of the transmission system

Ural trucks are valued for their high power characteristics, excellent load capacity, and driving dynamics. In many ways, the installed gearbox affects the performance of this vehicle. This device affects the power set.

A five-speed gearbox is installed on the Ural-4320. It has a long service life, perfectly tolerates the loads that fall on it. The gearbox housing Ural is attached to the clutch housing. A manual gearbox on a Ural car has fixed shaft axles. The upper crankcase cover is equipped with a gearshift mechanism.

The transmission system includes lockable cross-axle and center differentials. On the truck there is a box of dependent power take-off or KZOM.

It should be noted the presence of a transfer case for the Ural 4320. It is a 2-stage one, it affects fuel consumption for each kilometer traveled. This box is securely fixed to the frame with several special rubber pads.

The transfer box Ural is an additional gearbox. It provides a stable movement of the machine at low speed. The installed Ural power take-off is single-stage. It is necessary to drive auxiliary units.

Transmission Power Line Gear Shift Mechanism

Characteristics of gearbox problems

In order for the speed box to serve for many years, the owner of the Ural car must service it with high quality. Transmission system care is expressed as follows:

- replacement of used oil;

- replacement of worn components that relate to the gearbox.

We list the main reasons why the box breaks down:

- natural wear and tear of its components;

- the use by the car owner of low-quality gear oil;

- use in the repair of low quality spare parts;

- irregular maintenance.

The need to diagnose the Ural 4320 gearbox arises if it becomes difficult to shift gears, increased noise from the transmission side begins to be noted.

If a gear tooth breakage occurred in the Ural 4320 gearbox, then due to this, a characteristic noise from the gearbox side will be noted during movement on the road.

However, the appearance of noise can be directly related to the fact that the gearbox has a low amount of fuel.

In most cases, oil leakage is the result of natural wear of rubber seals. These consumables are not restored, but replaced with new ones. At the same time, the price for them remains at an affordable level.

When filling in new gear oil, the prescribed requirements must be followed. On the Ural-4320, you can check the level of the available oil using the existing pointer.

It is necessary to check the condition of the transfer case if difficult gear shifting has begun to be noted. As a rule, this occurs due to the fact that notches have appeared on the couplings.

Oil should be added to the transfer case through the top hatch. The transfer case requires about 3.5 liters of fuel.

For a speed box, it is recommended to use TSp-15K (mineral) gear oil. This fuel is used by many heavy vehicles.

The viscosity category for TSp-15K is 80W90. The use of high-quality oil helps to reduce wear of rubbing parts.

Since URAL machines are subject to heavy loads, you need to pay attention to the clutch mechanism. In some cases, if it is damaged, gears may not turn on well. If it is difficult to change gears, first of all, you should pay attention to the integrity of the rods, synchronizers. Repair and restoration work is best left to experienced professionals.

It is forbidden to continue to operate the truck, where there are worn-out engine or transmission mechanisms, urgent repairs are necessary. The box must be completely sealed.

A number of deformed parts can be restored by using methods such as welding, melting. Professional gearbox repair requires the appropriate equipment.

Repair of the checkpoint on the Ural 4320 must be carried out in a timely manner.

Components of the transmission system

Ural trucks are valued for their high power characteristics, excellent load capacity, and driving dynamics. In many ways, the installed gearbox affects the performance of this vehicle. This device affects the power set.

A five-speed gearbox is installed on the Ural-4320. It has a long service life, perfectly tolerates the loads that fall on it. The gearbox housing Ural is attached to the clutch housing. A manual gearbox on a Ural car has fixed shaft axles. The upper crankcase cover is equipped with a gearshift mechanism.

Gearbox Diagram

The transmission system includes lockable cross-axle and center differentials. On the truck there is a box of dependent power take-off or KZOM.

It should be noted the presence of a transfer case for the Ural 4320. It is a 2-stage one, it affects fuel consumption for each kilometer traveled. This box is securely fixed to the frame with several special rubber pads.

Power take-off

Related article: Installation and repair of the GAZ-24 checkpoint

The transfer box Ural is an additional gearbox. It provides a stable movement of the machine at low speed. The installed Ural power take-off is single-stage. It is necessary to drive auxiliary units.

Transmission Power Line Gear Shift Mechanism

Scheme URAL 4320

The Ural 4320 scheme of a truck with high driving performance and increased cross-country ability makes this vehicle extremely versatile.

Ural 4320 is used both in geological exploration and by enterprises with difficult operating conditions of equipment, as well as the armed forces of the Russian Federation. Thanks to the well-thought-out scheme URAL 4320 and the location of various components and assemblies, it has established itself as a reliable and practical car to maintain.

The successful combination of the URAL 4320 scheme for the location of the main components and assemblies, combined with a reliable and practical engine in operation, makes it possible to use the URAL 4320 both for transporting people and for delivering goods.

The universal scheme of the URAL 4320 chassis also allows it to be used as a tractor, dump truck or a platform for installing various equipment and special equipment based on the URAL 4320 scheme.

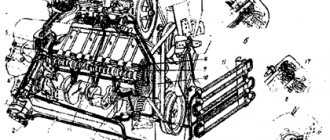

URAL 4320 engine diagram

Scheme of the Ural-4320 engine with a YaMZ four-stroke diesel engine with a turbocharger, as well as without it, with a power of up to 312 hp. With. ecological class from Euro-4. Below are the Ural 4320 engine diagrams with a detailed description of the power system, engine electrical equipment and lubrication system.

URAL 4320 engine diagram

Ural 4320 vehicles are equipped with various diesel engines with power up to 300 hp.

URAL 4320 engine diagram

Depending on the configuration, URAL 4320 is supplied in the following modifications:

- YaM3-236NE2 - six-cylinder engine with a power of 230 hp. and working volume - 11.15 liters, developing torque - 882 Nm;

- YaM3-236BE - a six-cylinder engine with a power of 250 hp. and working volume - 11.15 liters, maximum torque - 1078 Nm;

- YaM3-238 - eight-cylinder engine 240 hp and working volume - 14.86 liters, maximum torque - 882 Nm;

As can be seen in the diagram of the URAL 4320 engine, the YaMZ power unit is installed on four bearing supports: one front, one rear, and two middle ones - left and right.

URAL 4320 engine diagram - engine mechanism

The crank mechanism URAL 4320 is designed to convert the reciprocating motion of pistons into rotational motion, and vice versa. A detailed diagram of the URAL 4320 crank mechanism with a full description of the device and engine parts is presented below.

URAL 4320 engine diagram - Crank mechanism

The gas distribution mechanism URAL 4320 provides the inlet and outlet of an inert substance in the YaMZ-236 / YaMZ-238 engine system. The timing scheme URAL 4320 can have both a fixed valve timing and adjustable depending on the crankshaft speed.

URAL 4320 engine diagram - timing

These units are liquid cooled. The power supply system on the URAL 4320 diagram is a mechanical in-line injection pump.

Scheme URAL 4320 - injection pump

The unit drive installation diagram and power take-off modes in the URAL 4320 scheme are single-stage, fixed to the gearbox housing on the right side and designed to drive auxiliary units.

Scheme of the engine drive units URAL 4320

The URAL 4320 lubrication scheme is designed in such a way as to clean, lubricate and cool the engine as efficiently as possible.

URAL 4320 engine lubrication scheme

The lubrication system also serves to supply purified and cooled oil to the rubbing parts of the YaMZ-236 and YaMZ-238 engines to reduce the negative effects of friction, wear of engine components and parts, as well as optimal heat removal and removal of combustion products, slag and soot.

URAL 4320 cooling scheme The URAL 4320 engine air supply scheme consists of an air filter, low pressure pipelines, connecting hoses and fastening parts. Scheme URAL 4320 - cooling scheme

The scheme of the URAL 4320 lubrication system works on the principle of supplying oil to rubbing surfaces under pressure, as well as by splashing, in a self-lubricating way.

Scheme URAL 4320 - lubrication scheme

The scheme of the URAL 4320 lubrication system includes a YaMZ-236 / YaMZ-238 engine sump, an oil intake that provides primary oil cleaning and supply it to the pump, a full-flow filter and a centrifugal oil cleaning filter, a radiator, a filler pipe, an oil level indicator, a breather, a control - measuring instruments, lines and pipelines.

Scheme of the lubrication system URAL 4320

The oil in the system is indicated on the general lubrication scheme URAL 4320 and is supplied under pressure to rubbing parts, in particular to the main and connecting rod bearings of the crankshaft, as well as to the bearings of the camshaft of the URAL 4320 engine.

Lubrication scheme URAL 4320

Thanks to the well-proven URAL 4320 lubrication scheme, the rocker arm bushings, the main engine components, the fan drive fluid coupling, and the high-pressure fuel pump have a long working life.

Brake system URAL 4320 scheme

The URAL 4320 brake system diagram is presented in the form of a full-color schematic plan. The brake system URAL 4320 is designed to change the speed of movement or completely stop the URAL 4320, regardless of speed, direction of movement and bearing load.

Brake system URAL 4320 scheme

The URAL-4320 braking system diagram is a combination of three braking systems - working, parking and auxiliary.

Scheme URAL 4320 brake system

URAL 4320 has a diagram of a pressure control system and brake condition monitoring. Atmospheric cylinders have sensors for signaling the minimum air pressure in the brake circuit URAL 4329.

Scheme of brake system URAL 4320 In the scheme of brake system URAL 4320 the drive of brake mechanisms is mixed (pneumatic-hydraulic), dual-circuit, with separate braking of the wheels of the front and two rear axles. The control is carried out by a pedal in the driver's cab, connected by levers and rods with a two-section brake valve. Scheme URAL 4320-scheme of the brake system

Scheme of the working brake system URAL 4320 with drum type and internal pads with full interchangeability for all wheels. Each brake mechanism has two hydraulic cylinders made in one housing.

scheme URAL 4320 - scheme of the brake system service and parking brake

Brake pads are mounted on the support axles. The working brake mechanism is adjusted as the lining wears out by reducing the gap between the lining and the drum using eccentrics.

Gearshift diagram URAL 4320

The URAL 4320 gearshift scheme is a five-speed manual gearbox with a double-clutch for YaMZ-236 and YaMZ-238 engines.

Gearshift diagram URAL 4320

The scheme of the five-speed variable gearbox URAL 4320 KPP-236U is designed specifically for URAL vehicles with YaMZ-236 and YaMZ-238 engines of the euro-0.1 class without turbocharging with a double-plate clutch, has synchronizers in 2-3 and 4-5 gears.

Updated series URAL 4320

Scheme of electrical equipment URAL 4320

The URAL 4320 electrical circuit is single-wire, where the negative potential of the voltage source of the equipment and devices is connected to the vehicle's ground. The negative terminal of the battery is connected to the "mass" of the URAL 4320 by a remote switch. Below is a diagram of the electrical equipment URAL 4320 in high resolution.

Scheme of electrical equipment URAL 4320

In the URAL 4320 electrical equipment diagram, the connections between wires and devices are made using plugs and connectors. For convenience, the colors of the wires on the URAL 4320 electrical equipment diagram are presented in color.

Razdatka URAL 4320 scheme

Razdatka URAL 4320 scheme. The transfer case (URAL 4320 scheme) is a mechanical, two-stage transmission with an asymmetric center differential, which is installed using four rubber shock absorbers on the URAL 4320 frame.

Razdatka URAL 4320 scheme

As can be seen on the diagram of the transfer case URAL 4329, the differential of the transfer case of a planetary type with four pinion gears, sun 30 and crown 29 gears.

Scheme URAL 4320 - distribution scheme

The moment from the sun gear is transmitted to the shaft 35 of the front axle drive, and from the crown gear 29 to the shaft 21 of the rear drive.

URAL-4320

If a box with a winch and an additional power take-off is installed on the URAL 4320 transfer case, then when the bushing is turned on, the drive shaft gears are lubricated with high-pressure oil, which is supplied from the URAL 4320 transfer case crankcase using a plunger pump.

Gearbox diagram URAL 4320

The scheme of the URAL 4320 gearbox is made in the form of a color scheme. A description of the clutch and gearbox, as well as instructions for operation and maintenance, are given in the operating instructions for the Yaroslavl Motor Plant.

Gearbox diagram URAL 4320

The scheme of the URAL 4320 gearbox is a five-speed gearbox with constant mesh gears in all gears and with synchronizers for engaging the second, third, fourth and fifth gears. The gears of the URAL 4320 gearbox are helical, except for the first gear and reverse gear.

Scheme URAL 4320 - checkpoint

Gear shift operation on the URAL 4320 gearbox diagram is equipped with an upper crankcase cover. The URAL 4320 gearbox has proven itself to be reliable and easy to operate, capable of withstanding maximum loads without serious consequences.

Scheme URAL 4320 - Gearbox operation

Carry out a control inspection of the Ural-4320 car before leaving the park.

8. Check and, if necessary, adjust the gaps between the ends of the valves and the toes of the rocker arms of the following valves: inlet and outlet 1st cylinder; final 2nd cylinder; inlet 3rd cylinder; final 4th and 5th cylinders; inlet 7th and 8th cylinders.

9. Turn the crankshaft exactly one turn (360 °), check and adjust the clearances of the remaining valves: inlet 2nd cylinder; final 3rd cylinder; inlet 4th and 5th cylinders; exhaust and intake 6th cylinder; final 7th and 8th cylinders.

Normal clearance 0.25-0.30 mm; check the gap using two feeler gauges: a feeler gauge 0.25 mm thick should pass freely, and a feeler gauge 0.30 mm thick should “bite”.

Set the required gap in the following sequence:

- holding the adjusting screw with a screwdriver, release the screw locknut;

- set the desired clearance by turning the adjusting screw with a screwdriver;

- while holding the screw with a screwdriver, tighten the locknut with a wrench.

10. Replace the spark plugs, connect the high voltage wires and start the engine.

11. Listen to the operation of the engine. If the adjustment is made correctly, the engine will run smoothly, without valve knocks, “sneezes” in the carburetor and “shots” in the muffler.

12. Stop the engine and install the previously removed devices and parts on it in reverse order.

II way

To adjust the clearance in the valves of the remaining seven cylinders (after the 1st cylinder), it is necessary to turn the crankshaft with the handle half a turn, and adjust the clearances sequentially according to the order of operation of the cylinders 1-5-4-2-6-3-7-8. If the valves are adjusted on the engine removed from the car, or with the radiator removed from the car, then to rotate the crankshaft by 1 turn, it is necessary to put chalk marks on the crankshaft pulley, placing them at an angle of 90 ° with the position of the piston of the first cylinder in c. m.t. (compression stroke).

Carry out a control inspection of the Ural-4320 car before leaving the park.

1. Inspect the car from the outside (cabin, plumage, platform, transmission, chassis). If necessary, remove dust or snow, wipe the cab windows, lighting and light signaling devices, license plates and identification plates

2. Visually check the condition of the wheels and tires. Open the tire valves and check for air leakage by ear (loose nuts, air pressure drops in tires and air leaks are not allowed

).

3. Check:

the presence of fuel in the fuel tanks ( main - 210l, additional - 60l)

;

the level of brake fluid in the tanks of the main brake cylinders ( the level of brake fluid in the tanks should not reach the upper edge of the filler neck by 15-20 mm

)

4. Check the oil level in the crankcase of the engines and top up if necessary ( the oil level of a warm engine is controlled 5 minutes after it has stopped using the marks on the dipstick: it must correspond to mark “B”)

5. Check the coolant level in the cooling system and top up if necessary ( it is checked on a cold engine with the radiator and heater filler caps open: when filling with low-freezing liquid - along the upper edge of the radiator cooling tubes; when filling with water - above the upper edge of the cooling tubes by 20 —30 mm

).

6. If necessary, fill the reservoir of the windshield washer pump with water

7. In winter, when the ambient temperature is low, it is necessary to: install batteries if they were removed; check the operation of the curtains (blinds) of the radiator and the fastening of the insulating covers of the engine and radiator; check and prepare for operation the means of warming up the engine before starting

8. Check the operation of the parking brake system ( full braking should occur when the locking latch is moved by four to eight teeth of the sector

).

9. Start the engine, warm it up to a temperature of at least 600C, without exceeding the average crankshaft speed. While the engine is warming up, check for leaks of fuel, oil, coolant, shock absorber and brake fluids.

10. Listen to the operation of a warm engine at different crankshaft speeds.

11. Check the indications of instrumentation and the inclusion of signal lamps. The instruments must be in good working order and give the following indications:

oil pressure gauge - oil pressure in the lubrication system is not less than 1.0 kgf / cm2 at 600 rpm

;

coolant temperature indicator (by the time the car starts off) - not less than 600С

;

ammeter - battery charging current

;

fuel indicator - the amount of fuel in the tanks

;

tire pressure gauge — not less than 2.5 kgf/cm2

;

brake system pressure gauge - pressure 6.0 - 7.65 kgf / cm2

.

In a serviceable system, with the brake pedal in a free position, the pressure drop from 6 kgf / cm2 should not exceed 0.5 kgf / cm2 for 30 minutes

.

When you fully press the brake pedal for 30 seconds, there should be no noticeable movement of the arrow on the lower scale of the pressure gauge.

Dashboard

1. Two-pointer manometer; 2. Signaling device for emergency oil pressure drop

3. Coolant temperature gauge; 4. Oil pressure gauge

5. Tachometer; 6. Speedometer; 7. Signal lamp high beam headlights; 8. Current indicator

9. Fuel gauge 10. Tire pressure gauge 11. Cab light switch

12. Spotlight switch 13. Cabin heater switch 14. Road train sign light switch 15. EFU switch-on button 16. Alarm switch 17. Central light switch 18. Handle for manual control of fuel supply 19 and 24. Blocks of right and left control headlights 20. Wiper switch 21. Starter and instrument switch 22. Battery off button 23. Instrument backlight rheostat switch

12. Check the operation of the headlights, sidelights, rear lights, brake light, direction indicators, sound signals, wipers and glass washer. ( The light in the lighting and signaling devices should appear when the corresponding switch on the instrument panel is turned on. The sound signal should make a loud and clear sound. The wipers should work without jerking and jamming, their brushes should be adjacent to the plane of the windshield along the entire length. When you press the pedal washer pump water must be supplied to the glass

)

13. Check the axial movement of the steering column. ( Axial movement of the steering wheel is not allowed)

14. Check the winding of the cable on the winch drum, the reliability of the cable hook fastening, the position of the winch drum engagement lever ( The cable must be clean, without knots, laid evenly along the entire length of the drum without coil on coil (except for the fifth layer). The winch drum engagement lever must be in the down position).

16. Check the serviceability of the locking hooks of the tailgate of the platform, the hook of the towing device, equipment for transporting personnel ( The locking hooks must securely hold the board in the closed position.

)

17. Check the completeness, serviceability, stowage and fastening of tools and accessories for maintenance, entrenching tools and other personal property and equipment belonging to the car

16. If there is a trailer (semi-sight), check the reliability of the hitch, the fastening of the emergency chains, the position of the regime ring of the brake valve and the release valves of the air ducts on the vehicle and the trailer, the condition of the running gear and the platform of the trailer (The disconnection valves of the air ducts on the vehicle and the trailer must be open .

When driving with an unloaded trailer, the regime ring of the brake valve is set to the “P” position, and when working with heavily loaded trailers, to the “P” position)

19. At the beginning of the movement (on the way to the control and technical point), check the serviceability of the clutch, gearbox, transfer case, drive axles, steering, brake systems and speedometer. If there is a trailer (semi-trailer), check the operation of its braking system.

The clutch should disengage completely, ensuring ease and noiselessness of gear shifting, not slipping when the pedal is fully released.

When the machine is moving, there should be no self-disengagement of gears and increased noise in the gearbox, transfer case, drive axles.

The steering should operate without jamming, making it easy to change the direction of the vehicle.

The working brake system must provide simultaneous smooth braking of the wheels, stopping the car on the established braking distance.

The speedometer should show the speed of movement and the number of kilometers traveled by the car)

1Next ⇒

Recommended pages: