- home

- car transmission

- …

According to many wishes of my readers, I begin to talk about robotic gearboxes. But this is the first article that will be related to dual clutch, this is an “understanding” for subsequent articles, so that you already have an idea of \u200b\u200bhow a robot works with this system. Yes, and for the general development this is very useful information, so be sure to read and watch, at the end, as usual, there will be a video version ...

Well, at first, such information, many people ask me - “Sergey, tell me, please, is it possible to put a double clutch on a manual gearbox? In particular, to our VAZ?

I’ll answer right away - “Guys, it’s possible that this can somehow be “pranked” on our VAZs, but so far I haven’t seen such regular factory transmissions! Of course, there are videos on the Internet, such as - craftsmen do something shaman there, but regularly for ordinary cars - I PERSONALLY HAVE NOT MEET! Also not seen on foreign cars! Therefore, 90% of the dual clutch is installed on "robots" (robotic gearboxes). I leave 10% for “suddenly” maybe tomorrow our AVTOVAZ will start production!”

Okay, this question is closed, now let's get to the point, I offer some historical information.

History of appearance

The designer is rightfully considered the designer Adolf Kegress, it was he who for the first time in 1939 outlined the principle of double clutch. Later, its development in piece versions began to be used on racing tracks, on individual machines. But in wide application, everything remained on paper. And only in 1980, the Porsche company took up these developments in a new way.

It was this manufacturer who showed that it was possible to shift gears under load, that is, the engine speed was practically not reset. This development was truly revolutionary, because it allowed to reduce the effect of turbo lag , which is a huge problem for turbocharged engines. Now the switching occurred without jerks and dips, and therefore the torque is transmitted without loss.

Dual clutch box

Many mistakenly believe that a dual clutch gearbox is the same "mechanics" only with a "servo". But this is not at all the case - however, I can understand some "experts", they judge by an ordinary robot, that is, which is equipped with a conventional clutch, if you like - a single one.

Double clutch - makes changes not only to the device of the gearbox itself, but also to the device of the disk (and there are two of them) of the clutch.

If we take the gearbox itself and correlate it with the mechanics, then it turns out that the manual transmission has one drive shaft and all the main gears are located on it. There is also one clutch disc + "basket". This is a classic arrangement, but the dual clutch has a completely different design.

So: A complex, compound shaft is used here. If you want, then this is a “shaft in a shaft”. Roughly, you can imagine it like this - in a metal tube, they put a metal rod (which extends beyond the tube) and it rotates there. That is, both the tube itself and the shaft can rotate. This whole construction is this constituent element.

On one part of the shaft (let it be a “tube” for us), odd gears are installed, that is, this is the first - third - fifth gear. On the second part of the shaft (let it be a "rod") even second - fourth - sixth gears.

If you like, the dual-clutch transmission combines the work of, as it were, two manual gearboxes.

What happens in the final balance, but everything is simple - these, as it were, two “mechanical combined transmissions” work alternately, while one accelerates the car, the second is also involved, it already has engagement with the subsequent transmission.

That is, immediately and the first and second gears are switched on simultaneously, when the car starts. Then the box switches to the second, and again immediately, the third is activated, and so on. That is, the transmissions go alternately.

There is also a part of the robotic system here, these are servos or electric drives, which just monitor the switching and other actions (for clutch discs, for example). There is no torque converter or belt here, as we say in the " automatic or variator ", yet the similarity is very large with the mechanics.

So is it worth messing with DSG

The most important arguments for buying such cars in the secondary market is their efficiency. In addition, the cost of a used car with DSG is much lower than even analogues with a manual transmission.

On the other hand, you should not mess with such a transmission for people who do not have the slightest idea about the features of operation, the device and the correct diagnosis of a robotic gearbox. Simple, reliable, unpretentious transmissions - this is not about DSG.

Automatic transmission is chosen by motorists who are accustomed to operating the car in harsh conditions. Robotic transmission requires more gentle handling. Under such conditions, you can enjoy all the advantages of these units.

The principle of operation of the double clutch

The clutch is the key distinguishing feature of the entire transmission. It is worth talking about it separately and in detail.

As we already understood, we have two shafts, and for each of them, there is a clutch “package”, but combined into one housing. THEN there are two disks at once! One - is located on odd gears 1 - 3 - 5 (or in our example it is a “tube”). The second is for even 2 - 4 - 6 gears (that is, it is a “rod”).

How it works - when the car starts, one clutch disc is compressed, designed for first gear, the second gear is also engaged, but it is not yet involved, because its disc is open. After the speed in the engine has reached the desired mark (switching), the first disk is opened, and the second is compressed. And since the gear (second gear) is already engaged, the shift occurs instantly, without any shocks and losses.

Switching takes place literally in a fraction of seconds, imperceptible to the driver, the engine and the car as a whole. The average value is from 0.05 to 0.12 seconds.

The discs are compressed and opened alternately, turning on or off one or another gear.

Now there are two options for the clutch of a robotic gearbox, it is dry and wet.

The device and features of the DSG

The robotic gearbox is equipped with two clutch pedals. This allows you to quickly change the speed of the car while driving. Thus, DSG can be considered a conventional manual transmission, the gears of which are switched automatically.

In machines with conventional mechanics, when shifting up or down, the clutch disc is disconnected from the flywheel, and then connected back. During this process, the dynamics of the car are lost. "Robot" solves this problem by reducing pauses to a minimum.

This is achieved due to the fact that one clutch is responsible for an odd number of gears, and the other for even speeds. An even or odd clutch disc is alternately connected to the rotating flywheel. At the same time, there are practically no pauses between processes.

There are two types of modern DSG box: “wet” or “dry”:

- The first of them includes six gearshift steps. Its distinguishing feature is that the clutch disc "floats" inside the oil bath.

It copes well with high torque, so it is installed on more powerful cars, such as the Skoda Octavia.

- Since 2008, a new option has appeared - a seven-speed DSG7 version with a dry clutch. Such a gearbox is installed on machines complete with a less powerful power unit. For example, S-Tronic works on many Audi, Volkswagen Golf, Jetta and Passat models. This option proved to be problematic in practice.

Thus, when choosing a car with a DSG transmission, it is better to opt for a six-speed gearbox, as they are more reliable.

Dry and wet clutch

This is also an important point to note, some clutch option, others "dry". For a given period of time, "dry" is the most common, it is installed on almost 70% of cars equipped with such a transmission. "Wet" is put less often, but it works longer.

There are also manufacturers who combine two transmission options on their models at once, such as Volkswagen. He has DSG 6 which is wet and DSG 7 which is dry.

The differences here are critical:

The dry version is almost a complete analogue of a mechanical clutch, that is, the discs rotate in the air and they are physically similar to manual transmission discs. They are compressed or unclenched by means of electric actuators.

Wet option - here the discs rotate in a "wet" or oily environment. And the hydraulics compresses and unclenches them, very similar to the hydraulics on conventional automatic transmissions.

You probably want to - why is the wet version much more reliable than, say, the dry one? YES, everything is simple - disks that rotate in oil, they are cooled in it, so they can withstand high speeds and will not “burn out”. The dry version rotates in the air, and it is limited by speed, because from too high, in the literal sense of the word, it will burn and collapse.

What do automatic transmissions and DSGs have in common?

Before understanding the differences, let's find out what are the similarities between automatic transmission and DSG.

These boxes are automatic. This means that the driver no longer needs to press the clutch pedal, and then shift the selector lever and depress the accelerator. All this is done for him by the electronics inside the machine and the mechanical parts associated with it.

Thanks to automation, the human factor that affects delays when switching speeds is reduced. As you know, because of these delays, the car twitches when switching, jerks. Especially this happens with beginners, those who first got behind the wheel. In a car with an automatic transmission, shifts occur smoothly, without jerks and jerks.

Attention! Al4 DP0 automatic transmissions, which are installed on Peugeot-Citroen, Renault, can push and kick. But this is their design feature. If this happens often, and the driver feels that the force of the shocks is increasing or the car is thinking when switching, then this is a reason to take the car to a service center for diagnostics.

DSG and automatic transmissions do not differ from each other in the designation of modes. The letters are identical to those written on the box, which are “burning” on the dashboard monitor.

Now let's look at the main differences.

Pros and cons of dual clutch

As usual, there is no perfect system, here it is! Although now more and more manufacturers are switching to such robotic transmissions.

Positive points:

- Like it or not, but this gearbox is currently the most advanced. There are absolutely no jerks and jerks in it, which means smooth running at a height

- Fast shifting, 0.05 to 0.12 seconds

- Preservation of torque, for turbocharged engines this is critical

- Fuel economy compared to competitors. Even mechanics consume more

- Excellent acceleration dynamics. Again outperforms the competition

But the negative points are now also in bulk, and they are very significant.

- Very complex mechanism, both double clutch and all transmissions in general

- Small resource. As a rule, repairs will be required in 60 - 90,000 km

- Expensive, VERY expensive repairs

- There are few services that will repair QUALITATIVELY

- Shocks and jerks in intensive driving mode, that is, acceleration to a stop, and so on several times, and quickly! In the "racing" mode, I would say. When downshifting, it can shift gears more slowly, about 0.4 - 0.6 milliseconds.

In general, guys, now there is a lot of hype about such transmissions, especially about DSGs, people are afraid to buy them because of their low resource. Even all those pluses that exist - economy, fuel, dynamics, and jerk-free movement - FAD after you find out the price of the repair! Now often it is about 10 - 20% of the cost of the car as a whole. VERY EXPENSIVE! And what is most offensive, let's say if your automatic transmission started to kick , then you can still ride it. But on a double clutch, it is unlikely, because it dies immediately and all.

But manufacturers do not lose hope, the quality of materials and the technical component are growing every year, and Volkswagen assures that it has “almost” defeated the problem of parts wear, the resource has been increased. In addition to him, they install such transmissions on their cars - Audi, BMW, Chrysler, Ford, Volvo.

Now the video version of the article, we are watching.

This concludes, I think it was useful. Read our AUTOBLOG.

Similar news

- Robot (RKPP) - a robotic gearbox. What it is? …

- Automatic transmission clutches. What is it, how do they work and why do they burn?

- Hardware or partial oil change in automatic transmission. How to do the right...

Add a comment Cancel reply

Car clutch - how it works and how it works

The clutch is necessary to disconnect the engine from the rest of the transmission for a short time and smoothly connect them during gear changes and the start of the car. In addition, the clutch protects the transmission parts from shock loads.

On cars, electromagnetic, hydraulic, but most often friction clutches are used.

electromagnetic clutch

When an electromagnetic field occurs, the driving and driven parts of the electromagnetic clutch are interconnected directly or through a ferromagnetic powder, which loses its mobility under the influence of an electromagnetic field.

Similar clutches were used on cars designed for the disabled. Now electromagnetic clutches are often used in the climate control systems of cars.

hydraulic clutch

In the hydraulic clutch between the driving and driven discs having blades, fluid circulates. The rotation speed of the driven wheel depends on the amount of liquid. If it is completely removed, the driven wheel stops. This clutch significantly increases the smoothness of the car, but complicates its design.

friction clutch

In a conventional friction clutch, the torque is transmitted by frictional forces that occur between the driving and driven parts of the clutch pressed against each other.

In cars, you can find one, two and multi-plate friction clutches whose discs can work both in liquid (wet clutch) and without it (dry clutch).

Dry single plate clutch

Most often in modern cars, a dry single-plate clutch is used. It consists of the following parts:

- clutch basket;

- pressure disc;

- driven disk;

- diaphragm spring;

- release bearing;

- clutch release fork.

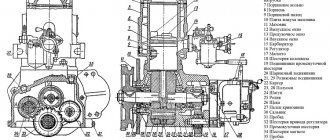

Scheme of a single-plate clutch: 1 - housing; 2 - tangential spring; 3 - support bearing; 4 - crankshaft; 5 - damper spring; 6 - driven disk; 7 - pressure plate; 8 - flywheel; 9 - clutch basket; 10 - ring; 11 - spacer bolt; 12 - diaphragm spring; 13 - release bearing; 14 - guide; 15 - input shaft of the gearbox; 16 - clutch release fork; 17 - working cylinder.

On some vehicles, instead of a diaphragm spring, coil springs are used, located around the circumference of the pressure plate and levers located radially.

The clutch basket assembly with diaphragm spring and pressure plate is attached to the engine flywheel and rotates with it, playing the role of the leading part of the clutch. Between the flywheel and the pressure plate is a clutch driven disc mounted on the splines of the input shaft of the gearbox.

The principle of operation of the clutch

If the clutch is engaged (the clutch pedal is not pressed), the pressure plate, under the action of the diaphragm spring, presses the driven disc against the flywheel and through this “sandwich” the torque is transmitted from the engine to the gearbox.

When the clutch pedal is depressed, the clutch actuator parts move the clutch fork. It moves the release bearing, which in turn acts on the central part of the diaphragm spring. She arching takes the pressure plate away from the slave, freeing him. As a result, the engine is disconnected from the gearbox.

On the driven disk, on its peripheral part, two rings made of a special friction material are fixed (glued or riveted) on both sides. The central part of the disk has a slotted hole. With their help, the driven disk is connected to the input shaft of the gearbox. The peripheral part is connected to the central part through damper springs located along the circumference. Springs are necessary to ensure smooth operation of the clutch and dampen torsional vibrations.

The pressure plate is connected to the clutch basket using elastic plates located tangentially to the outer circumference of the disc.

The diaphragm spring is attached to the pressure plate with its outer circumference, and the release bearing presses on its central part (more precisely, on the ends of the radial petals) when the clutch is turned off.

engine flywheel

The flywheel is traditionally a flat disc mounted on the end of the crankshaft. On its outer circumference, a gear rim is pressed in, which is necessary for connecting the engine starter to the crankshaft when starting the engine.

But in modern cars, the flywheel design is somewhat different. The fact is that there are always vibrations in the engine, no matter how it is balanced. They become more noticeable at low engine speeds. The transmission also adds vibration.

A massive flywheel helps smooth out vibrations. Part of the work of ensuring rotation without jerks is taken over by the damper springs of the clutch disc. But the heavy weight of the flywheel increases the weight of the engine and prevents it from quickly gaining momentum, reducing the throttle response of the car.

dual mass flywheel

Therefore, the so-called dual-mass flywheels are now used, consisting of two parts connected to each other through elastic elements. In one version of the design, these are two parallel disks connected through springs located along the circumference.

Another option is two concentric discs interconnected by spring-loaded rods.

The weight of the flywheel is reduced, it cools better, the design and weight of the clutch disc are simplified (no damper springs). In addition, impact loads on gearbox parts are reduced, which reduces their strength and, as a result, weight.

double disc clutch

On vehicles with powerful engines, double-disc clutches can be used, which allow the transmission of large torque with a small device. The clutch uses two driven discs installed in series through an intermediate disc. The number of friction surfaces in this case increases to four.

Scheme of a double-disk clutch: 1 - housing cover; 2 - dual-mass flywheel; 3 - drive plate; 4 - driven disk 2 with damper springs; 5 - spacer; 6 - driven disk 1; 7 - pressure plate; 8 - sensor spring; 9 - adjusting ring; 10 - diaphragm spring.

Video - car clutch:

The video complemented the article perfectly. Good luck on the roads!

(No one has rated yet. Be the first!)

auto-i-avto.ru