Technical characteristics of the tractor T-170, bulldozer T-170

Tractor T-170, bulldozer T-170

(based on the T-10.01 tractor) - was developed and put into mass production at the Chelyabinsk Tractor Plant) in Chelyabinsk. The T-170 tractor, the T-170 bulldozer is a Soviet agricultural and industrial caterpillar tractor, which is a more modernized version of the T-100 tractor. Tractor T-170, bulldozer T-170 is available in two versions: conventional and swamp (T-170B) with an increased track area.

Bulldozer T-170, tractor T-170 ChTZ

Tractor T-170, bulldozer T-170 is used as part of a bulldozer-ripping unit, including as a base machine for TR-12 and TR-20 pipelayers, pile driver.

Tractors and bulldozers T-170 are representatives of the most massive traction classes of 10-15 tons. These bulldozers work in various industries, as well as in road and municipal services, and in logging.

Bulldozer T-170, tractor T-170 in the timber industry.

Tractors and bulldozers T-170 ChTZ have a long service life and increased maintainability, which makes it possible to operate bulldozers and tractors T-170 in difficult climatic conditions.

Engine

Bulldozer T-170, tractor T-170 is supplied with a four-stroke diesel engine D-160/D-180, turbocharged, up to 180 hp.

Engine D-160 ChTZ

D-160 and D-180 engines have the following specifications:

Specifications D-160 / D-180 | |

| Engine brand | D180.111-1(D-160.11) |

| engine's type | Four-stroke diesel, turbocharged, multi-fuel |

| Engine power, kW (hp) | 125 (170) |

| Specific fuel consumption, g/kW*h (g/l.s.h.) | 218 (160) |

Bulldozer T 170 is an indispensable equipment for road and construction work

Bulldozer T-170

- A bit of history

- Device technology

- Advantages and disadvantages

Bulldozer T 170 was produced at the Chelyabinsk Tractor Plant. Many technical characteristics of the machine were taken from the T-130 caterpillar tractor. The car was produced for 14 years. Not a single construction or road work could do without this technique. On the basis of this bulldozer, about 80 types of heavy equipment were produced.

A bit of history

The Chelyabinsk Tractor Plant was founded in 1929. Heavy agricultural machinery has become the main specialization of the enterprise. ChTZ tractors were present at all major construction projects that were carried out throughout the territory of the former Soviet Union.

But the year 1988 was a truly high point for the enterprise. Tractor T-170 came off the assembly line of the plant. This is a heavy tracked vehicle of the 10th traction class . The technique had a number of undeniable advantages:

Bulldozer T-170

- simple but reliable assembly;

- power;

- high permeability;

- low cost.

Given the fact that the T-170 tractor became the basis for several series of tracked vehicles, the question arose with the repair and maintenance of equipment. Thus, the Uralremtrak enterprise was founded. Repair and maintenance of tracked vehicles was carried out here. Both plants are successfully operating at the present time.

Interesting! Tractor T-170 performed a wide range of construction work. In this regard, 7 varieties of caterpillar tracks were developed. This allowed the technique to successfully cope with the tasks.

Device technology

Consider the main components and characteristics that the T-170 bulldozer has.

Chassis

The T170 tractor has a welded carrier frame equipped with caterpillar bogies. The caterpillar mover is mounted on three points, the suspension is semi-rigid, but supplemented by a rigid balance beam. The rigidity required for work is provided by side clutches of a spatial type. Such a frame and suspension scheme provide the equipment with excellent flotation on hard ground.

If the machine is designed to work in wetlands, longer spars are installed on the frame. The standard equipment provides for the installation of five rollers for the track. Machines with high cross-country ability and specific low ground pressure are equipped with wider tracks and seven rollers.

transmission system

The transmission scheme includes a four-shaft gearbox, a permanently closed clutch and a power take-off shaft. Gear shifting is carried out by constantly engaged gears. This provides the car with 8 forward and 4 reverse speeds.

Such a transmission scheme allowed the machine to maximize all its capabilities. On some machines, a six-speed gearbox could be installed.

Some modifications were produced with a hydromechanical transmission scheme. This provided switching between operating modes regardless of the load.

Bulldozer T-170

Cabin

Unlike most machines that were produced in the USSR, the T-170 bulldozer was equipped with a completely comfortable cab. This is an all-metal frame cabin, with panoramic windows.

The driver's seat could change its configuration depending on the dimensions of the tractor driver. There was an oil cooler and air conditioning.

Using the dashboard, you can control the operation of the main components and systems. For example: fuel level in the tank and oil pressure, clogging of the hydraulic system and air cleaner, crankshaft speed and hours worked. Taking into account all the features, the T-170 cabin could quite confidently compete with Western counterparts.

Hydraulics and electrics

The operation of attachments is provided by a hydraulic system, the main unit of which is the NSh-100 pumping station. The pump is mounted directly on the engine. Depending on the modification of the bulldozer and additional equipment, the hydraulic system may have a different configuration.

The work of installed electrical appliances is provided by two batteries and a starter. In this case, the starter can only interact with one battery at a time, so you have to periodically swap them. The voltage required for operation is 24V.

Bulldozer T-170

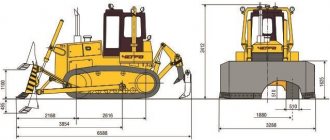

Specifications:

| Weight (base model) | 15 990 kg |

| Parameters: length/width/height | 4 210/2 480/3 250 mm |

| Track width | 1 880 mm |

| ground pressure | 0.03-0.04 MPa |

| Fuel tank capacity | 300 l |

| fuel consumption | 160 g/l hour |

Optional equipment

Bulldozer T-170 is mainly used in construction. The choice of attachments also depends on this. The tractor can perform the function of a pipelayer, be aggregated with a trailer crane, rippers and a pile driver . D

To work with trailed equipment, rigid or pendulum trailers are used. The most common is the bulldozer blade. There are five such ovals in total, and each is designed for a certain type of work:

- straight;

- direct rotary;

- direct marsh;

- carbonic;

- hemispherical.

Ripper on T-170

Advantages and disadvantages

The T-170 bulldozer was discontinued in 2002. But despite this, the car can often be found on construction sites. This suggests that the technique is quite coping with the tasks assigned to it.

Powerful machine can work with any soil. The designers have well thought out the scheme for replacing attachments. It is possible to change one dump for another within a few minutes.

Thanks to the installed hour meter, you can easily determine the period for changing oil or grease.

It is worth noting the convenience of transporting equipment to the place of work. The T-170 tractor has dimensions that are designed specifically for railway platforms.

True, when transporting a car by rail, it is necessary to dismantle attachments.

Thanks to the liquid cooling of the main diesel engine and the cold start system, the bulldozer starts up even at a temperature of -40 degrees. There are no problems with spare parts. Uralremtrak regularly produces spare parts and carries out repairs and maintenance of all tractors created on the basis of the T-170.

It was not without its shortcomings. The weakest point of the bulldozer are the friction clutches. The clutch was completely copied from the T-130 and for the entire time the T-170 bulldozers were produced, the developers did not come up with anything new. Therefore, friction clutches often need to be replaced.

The steering is quite complex and loses a lot to European and Western cars of a similar class. Perhaps, under the Soviet Union, the comfort of the cab was admired, but compared to modern tractors, the tightness of the tractor driver's workplace is almost zero.

The T-130 bulldozer is a good and multifunctional machine. Design flaws in technology are more than offset by low cost and ease of use.

Source: https://fermerznaet.com/selhoztehnika/traktor/buldozer-t-170.html

Attachment T-170

Tractor T-170, bulldozer T-170 can be equipped with various attachments: straight or hemispherical blade (shovel), single or multi-tooth ripper (rooter).

Bulldozer T-170 with direct blade.

Characteristics of bulldozer equipment T-170 | ||

| blade type | Hemispherical | Straight |

| Changing the cutting angle and blade skewing angle | Screw and hydraulic braces | |

| Drawing prism volume, m3 | 4,75 | 4,28 |

| Blade width, m | 3,31 | 3,42 |

| Height at a cutting angle of 55 degrees | 1,31 | 1,31 |

| Maximum lift, m | 1,02 | 1,02 |

| Maximum depth, m | 0,44 | 0,44 |

| Maximum skew, m | 0.63 (10 deg.) | 0.63 (10 deg.) |

| Cutting angle adjustment, deg | 10 | 10 |

| Weight, kg | 2313 | 2240 |

Single-tooth ripper of the bulldozer T-170

Characteristics of ripping equipment T-170 | ||

| Type | multi-pronged | single tooth |

| Max number of teeth | 3 | 1 |

| Number of tooth positions (vertical) | 3 | 3 |

| Maximum depth, mm | 650 | |

| Loosening angle, degrees: | ||

| - with a short tip | 45 | 45 |

| - with a long tip | 30 | 30 |

| Weight, kg | 2245 | 1555 |

Tractors and bulldozers T-170 deserve a mixed rating. Their advantages include a simple design and low cost (compared to tractors of a similar class).

Specifications T-170

The cabs that were equipped with the T-170 bulldozers had a frame structure. Their installation was carried out on a vibration-isolated platform.

Photo source: wikipedia.orgOne of the modifications: T-170 with DZ-171.1 bulldozer equipment

The undercarriage standardly had five-roller bogies (this solution was traditional for bulldozers of the 10th traction class). If the buyer planned to operate the machine on soft soils, it was possible to install seven-roller carts. Also in this case, wider shoes (900 mm) were offered. As a result of these decisions, the pressure on the ground decreased. Bogie suspension - semi-rigid three-point. The tension mechanism was hydraulic. Type of shoes - single-ridged.

| Number of track rollers per side | 5 |

| Number of carrier rollers per side | 2 |

| Track shoe width | 500 mm |

| Number of track shoes per side | 38 |

| Ground pressure | 0.076 MPa |

Gearbox - four-shaft. Its design provided for gears of constant meshing, thanks to which it was possible to provide eight forward gears and four reverse gears. Clutch - permanently closed type, dry friction. The shift lever and range select lever were used to shift gears. For safety reasons, starting the engine was not possible in cases where the right-hand range lever was not in neutral. The braking system was represented by multi-disc onboard clutches and dry friction band brakes. Type of hydraulic system - separate-aggregate, with a gear-type pump.

Photo source: wikipedia.org Photo by ChTZ T-170

The air cleaner that the bulldozer was equipped with was capable of operating in two stages of cleaning: in the first case, the “multi-cyclone” technology was used, which provides automatic dust removal, in the second, paper filter elements were used.

Here is the data on the main filling capacities:

| Cooling system | 60 l |

| Engine lubrication system | 32 l |

| final drive (each) | 12 l |

| Hydraulic system | 100 l |