An indispensable assistant not only for people professionally engaged in agriculture, but also for owners of summer cottages, small agricultural land, farms is the OKA - MB-1 walk-behind tractor. Being a universal mechanical device, the functions of a walk-behind tractor are not limited solely to plowing and plowing the soil. The unit is also used for the following purposes:

- hay harvesting;

- mowing grass;

- mechanical cleaning of sidewalks and paths in personal plots;

- transportation of small cargoes;

- snow removal.

This machine is multifunctional

Belts for Neva walk-behind tractors: types, sizes, self-tensioning

As you know, walk-behind tractors can be of two types. The first of them work on a chain, and the second - on a belt drive. In the second case, the belt drive is used to transmit torque from the motor to the attachments of the walk-behind tractor, and also plays the role of a clutch and transmission. We propose to consider the principles of installing belts on the Neva walk-behind tractor, as well as do-it-yourself methods for adjusting them.

Rules for choosing belts for Neva walk-behind tractors

The model range of Neva walk-behind tractors is not limited to only one representative.

On the contrary, there are several modifications of agricultural units, for each of which belts of a certain type are suitable. On the MB-1 walk-behind tractor, as well as for the Neva MB-2 walk-behind tractor, a V-belt drive is used predominantly. The use of a wedge gear allows the unit to move both in the forward and in the rear direction. In the event of a malfunction of the V-belt mechanism, the Neva brand machines will not work.

Motoblocks MB-1 are equipped with a V-belt drive forward and reverse. At the same time, the MB-2 modification is equipped only with a forward gear. Such a difference in the design of the two models of units does not allow using the same type of belts for them. On the contrary, in order to choose the right belt for the Neva walk-behind tractor, a number of the following factors should be studied:

- The type of belt that exactly matches your model of walk-behind tractor;

- Element dimensions;

- The degree of tension of the element;

- Type of wedge gear.

By carefully studying each of these characteristics, you will be able to accurately select spare parts that are suitable specifically for your unit model.

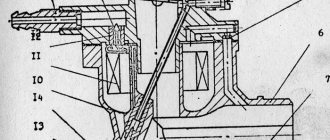

Forward and reverse belts of the OKA motoblock

Belts on the OKA 2 walk-behind tractor: forward and reverse. Combined with other constituents such as:

- front pulley;

- reverse pulley;

- drive pulley;

- gear pulley;

- thrust;

- spring;

- front lever;

- reverse lever.

function The belt drive parts form the clutch. This mechanism is necessary for transmitting torque from the crankshaft of the motor to the gearbox. In turn, the clutch together with the gearbox (gearbox) forms the OKA transmission.

Types of belts for motoblocks Neva

There are three types of belts that are installed on walk-behind tractors. They include:

- V-belts;

- Elements of the forward course;

- Reverse belts.

In order to accurately select a drive belt for Neva brand units, it is best to use the table, which indicates the correspondence of the elements to a specific model of walk-behind tractor.

This table will tell you how to choose a belt for the Neva walk-behind tractor, based on the modification of the agricultural unit.

Sizes of belts for Neva walk-behind tractors

To determine which part is suitable for your agricultural machine, a special table will help. Before using the table, measurements should be taken between the pulleys and rollers on which the new part will be installed. This will help determine the exact length of the new element.

Tensioning the belt of the Neva walk-behind tractor - how to do it yourself?

In the design of the Neva MB-1 and MB-2 walk-behind tractor, the location of the belts is slightly different. Therefore, the installation algorithm for both models will also have certain differences. To tighten the belt on the Neva MB-1 walk-behind tractor, you must follow the following procedure:

- First of all, it is necessary to remove the casing from the V-belt mechanism;

- Then carefully remove the rear bar from the pulley;

- Using a wrench, loosen the spring-loaded roller;

- Dismantle the old belt and tighten the new element;

- After that, install all previously dismantled parts of the walk-behind tractor.

Tensioning the belt of the Neva walk-behind tractors: we perform at home

After the belts are installed on the pulleys, we proceed to the final step in their maintenance - the tension, presented in detail in the video instruction. Almost always, a new cord gives sagging, which can be determined by hand. It is unacceptable if the belt "dangles", sagging in different directions by 1 cm or more.

This may lead to:

- increased vibration on a certain side of the walk-behind tractor;

- the effect of "slipping", due to which the motor will not be able to develop the necessary traction for plowing, hilling and other difficult operations;

- stupor and strong smoking at idle, after which a bluish coating may appear on the pulleys.

Adjusting the belt on the Neva MB-2 walk-behind tractor is carried out in the following order:

- As in the first case, remove the casing from the V-belt mechanism;

- Using a special screw, loosen the tension of the regular belt;

- Unscrew all the screws that hold the bracket to the body of the walk-behind tractor;

- Pull out the old belt and adjust the pulleys;

- Before putting the belt, be sure to wipe the space between all visible parts, and blow out the hoses that have free access;

- When installing a new belt, install one end of it on the gearbox shaft, and the other on the pulley located in the engine;

- At the end, assemble the structure in reverse order. You can learn more about installing belts on Neva walk-behind tractors from the video.

How to replace drive belts on Neva walk-behind tractors MB-1 and MB-2: step by step instructions

Based on the differences in the location of the belts on these two walk-behind tractors, we will consider the processes separately.

For "Neva" MB-1:

- disconnect the shield, for which 2 bolt ties are unscrewed and the protective cover is removed from the gear pulley;

- do not completely unscrew the connection of the guide pulley;

- slowly remove the reverse belt;

- loosen the ties, move the limiter pins and remove the forward gear belt;

- we take new serviceable belts and apply them to the grooves of the required pulleys. After that, we fix them with bolts that were removed in the previous steps.

"Neva" MB-2:

- disconnect the shield and casing;

- be sure to remove the spring that provides tension;

- unscrew the screw fasteners and unscrew the limiters that hold the belt on the motor pulley. Before proceeding to the next step, you need to make sure that the grooves of the motor shaft and the gearbox are in the same plane. According to instrumental measurements, the flatness between them should not go beyond 0.01 cm;

- if necessary, adjust the pulleys. The easiest way to do this is to move the motor in the longitudinal plane;

- we adjust the tension pulley by adding or removing an element located between the disk and the bracket;

- we install a serviceable belt for the Neva MB-2 walk-behind tractor, starting from the gear part.

Further assembly of the V-belt mechanism is carried out in the reverse order of the disassembly process. An important point that is often overlooked by users is the violation in the amount of range between the protective cover and the harness. According to the technical documentation, it should be at the level of 2-3 mm.

Another fact also matters. If 2 belts are installed on the walk-behind tractor, but only one of them is worn out, both drives must be replaced. If this is not done, the newly installed cord will experience more loads than the old one and will wear out ahead of schedule.

Features of motoblocks "Neva"

There are many modifications of this walk-behind tractor (MB-2, MB-23, etc.). Each device has its own type of belt. Mostly used motoblocks MB-1 - motor cultivators of the old modification. It should be noted that the operation of the MB-1 and MB-2 devices is based on the V-belt transmission mechanism. This system ensures the movement of the unit forward and backward, respectively, without its help, the device simply will not work. In the motoblocks of the MB-1 modification, a V-belt transmission of both moves is built in. In MB-2 releases, only one forward gear is used. Based on this, in order to choose a belt for the Neva walk-behind tractor, you should stock up on the following data:

- you need to know the type of belt that matches your specific model of the unit;

- belt length;

- the degree of tension of the part;

- type of V-belt transmission (for certain modifications).

Replacing belts on Neva walk-behind tractors MB-1 and MB-2

It is necessary not only to choose the right belt for the Neva walk-behind tractor, but also to know how to install it. First make sure you get all dimensions correct. The belt replacement processes for the units of these two samples are different from each other. For MB-1, the sequence of actions is as follows:

- the first step is to remove the casing from the V-belt mechanism;

- then you need to carefully remove the rear bar from the pulley;

- take the key and make the spring-loaded roller weaker;

- the part itself is removed;

- the next step is to tighten the new belt;

- in the end, we return to the place those parts that were removed and strengthen them.

For MB-2 we see a slightly different course of action:

- the first action is similar to the previous scheme;

- then in the same way we loosen the tension of the strap;

- next you need to unscrew those screws that secure the bracket;

- pull out the belt;

- we make adjustment of pulleys;

- we put another part into the mechanism (remember that you first need to tension it on the gearbox shaft, and then on the pulley located in the motor);

- collecting everything again.

As a rule, the belt is reinstalled if some kind of breakdown occurs during operation. But sometimes the owners of the equipment just want to replace the part with a newer and not so worn one. In addition, there is another way to increase the productivity of the walk-behind tractor - you can put a second belt. Installing the second belt on the Neva walk-behind tractor takes approximately ten minutes.

In general, when replacing a belt on the Neva, one should take into account what developments this or that modification is based on. For example, the Neva-mini (MK-100) differs from other models in that its production uses designs made back in Soviet times. The following video will tell you more about choosing a belt and replacing it.

How to replace the belt on a walk-behind tractor with your own hands?

- If the owner of the unit sees a problem, he must turn on the neutral gear of the gearbox, turn off the engine and move the unit to the place of repair work;

- The protective casing and worn belts should be removed. If they are not completely torn, but are in critical condition, we cut them with scissors and remove them;

- If a person sees that one of the belts is still in good condition, both products should still be replaced, because when installing a new one, the tension level will change and it will be he who will take the main load, thereby reducing the period of high-quality operation. Therefore, pair replacement is a charming procedure;

- It is necessary to remove the pulley from the engine drive shaft, and put new belts on the pulley located on the shaft of the walk-behind tractor gearbox, which cannot be removed;

- We take the “separated” pulley and carefully pull the belts over it. Only after the “dressing” is completed, we mount the part on the motor shaft. An important point: we must not forget about the key, because without it the pulley will not rotate;

- In the process of installing the belts, it is necessary to bring them on top of the tension rollers and make sure that everything is done correctly (there is no skew);

- At the end, place the protective casing in place and enjoy the operation of the walk-behind tractor with new belts.

Having received an answer to the question “How to tighten new belts?”, You can safely carry out this procedure on your own without fear and worries. Everything is very simple and with experience, replacement will become commonplace, carried out quickly and efficiently.

Belts for the Neva walk-behind tractor: features, dimensions, tension

All models of walk-behind tractors are of two types. One operates on a chain, and the second on a belt drive. If a second structure is installed, the torque from the engine is transmitted to additional attachments. Belt drive implements clutch and transmission tasks.

Install the belt on the Neva walk-behind tractor and you can adjust it yourself.

Belt for motoblock Neva

Belt dimensions for the Neva walk-behind tractor - information necessary for every owner of this equipment.

Belt type, length, tension and adjustment, V-belt transmission malfunctions - questions that we will try to figure out in this article. When writing this article, I came across one interesting fact: information about the types and sizes of belts for Neva walk-behind tractors and others on the network is presented mainly by online stores that offer to buy their goods. In this case, errors are very common.

Therefore, when buying a belt, you need to be very careful, and focus on the operating instructions for your walk-behind tractor. The data on this page is collected from the catalogs from Krasny Oktyabr and from the instructions for walk-behind tractors.

There are a large number of modifications of Neva motoblocks. It happens that there are different belt sizes for the MB-2 walk-behind tractor with different engines (see 3 and 4 lines of the table below)

Table of used belts for walk-behind tractors and cultivators Neva

| Type of walk-behind tractor Neva | Belt type |

| MB-1 old modification | Drive belt A-1180 VN-T GOST 1284.1-80 - GOST 1284.3-80 (forward drive) Drive belt 0-1400T GOST 1284.1-80 - GOST 1284.3-80 (reverse drive) |

| MB-1 | A53 (1380) |

| MB-2 | А-45 13×1143Li A1180Ld or А1180 GOST 1284.2-89 |

| MB-2S-9.0 PRO | A46.5 A (1213) |

| MB-3 | A52 13x1320 Li A1350Ld |

| MB-23 | А49 (data differ in different catalogs) A50 13×1270Li A1300Ld |

| MB Compact | A47 (1200 Li A47 (1230 prof A)) |

| MK-75 | FSCOUZ36 |

| MK-80 | A37 13940 Li A 970 Ld |

| MK-80R | Z31 1/2 10x805Li Z825Ld |

| MK-100 | A-100 GOST 1284.1-89 |

| MK-200 | A44 |

Table of applicability of pulleys and belts on Neva MB 2 walk-behind tractors

| Modification | Engine | Belt type | |

| Model | Ø to / in | ||

| MB-2K-6.2 | DM-1K (ZAO Krasny Oktyabr-Neva) | Ø25 | А1180 GOST 1284.2-89 or А45 13×1143Li А1180Ld |

| MB-2K-7.5 | DM-1K-7.5 (ZAO Krasny Oktyabr-Neva) | Ø25 | |

| MB-2B-6.0 | I/C 6.0 (Briggs & Stratton) | Ø19 | |

| MB-2B-6.0 PRO | Vanguard 6.0 (Briggs&Stratton) mod.117 | Ø19 | |

| Vanguard 6.0 (Briggs&Stratton) mod.118 | |||

| MB-2B-6.5 PRO | Vanguard 6.5 (Briggs & Stratton | Ø19 | |

| MB-2B-7.5 | Vanguard 7.5 (Briggs&Stratton) mod.1384320190Е1DD1001 | Ø19 | |

| Vanguard 7.5 (Briggs&Stratton) mod.1384320162Е1DD1001 | Ø25.4 | ||

| MB-2B-5,5M | I/C 5.5 (Briggs & Stratton) | Ø19 | |

| MB-2N-5.5 | HONDA GX200 | Ø19 | |

| MB-2B-6.5 | I/C 6.5 (Briggs & Stratton) | Ø19 | |

| MB-2S-6.0 PRO | EX17 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| MB-2S-7.0 PRO | EX21 (Robin SUBARU) | Ø19 | |

| Ø20 | |||

| In more detail, the types and sizes of the used belts, pulleys and cables for Neva walk-behind tractors and cultivators of other modifications can be found here | |||

Download the table of applicability of pulleys and belts for Neva walk-behind tractors of various modifications with various engines: tablica-skivov-remnei2013.xls

Designation of V-belts

The V-belt drive for walk-behind tractors of types MB - 1 and MB - 2 performs the function of a transmission and a clutch mechanism and provides:

- transmission of torque from the crankshaft of the engine to the input shaft of the gearbox:

- disconnecting the engine from the gearbox during gear shifting and smoothly connecting them again, excluding sudden changes in the load on the engine:

- smooth starting of the walk-behind tractor and its stop without stopping the engine.

The V-belt drives of the MB-2 and MB-1 walk-behind tractors are structurally different, which is caused by the use of various types of gearboxes in them

Possible malfunctions of the V-belt transmission

| Nature of the fault | Possible reason | Elimination Method |

| Incomplete clutch disengagement | Belt tension with clutch lever depressed is too high | Set the normal tension of the belt with the clutch lever pressed, ensuring the deflection of the upper branch of the belt within 8-10 mm when a force of 5 kgf is applied to its middle part between the pulleys. |

| Incomplete engagement of the clutch | 1. Belt tension when the clutch lever is pressed is less than normal 2. Belt delamination | 1. Same 2. Replace belt |

Checking the tension and adjusting the belt of the Neva walk-behind tractor

Features of belts for motoblocks Neva

The range of motorcycles is quite wide.

Accordingly, the selected belt for the Neva walk-behind tractor must match the model of agricultural machinery used. On the MB-1 and MB-2 walk-behind tractor, a V-belt drive is often installed. It is thanks to the wedge gear that the unit is able to move forward and backward. If the V-belt mechanism of the machine fails, the walk-behind tractor will not be able to function normally.

Motoblocks MB-1 have forward and reverse gears. MB-2 models only move forward. Due to this difference, the same belts cannot be used.

It is not difficult to choose a drive belt if you pay attention to the following nuances:

- the selected type must match the model of equipment;

- belt dimensions;

- part tension stage;

- type of V-belt transmission.

If you look at the above data, you can choose the right belt for a specific model of walk-behind tractor.

Types of belts installed on the equipment:

- wedge;

- Forward details;

- Reverse elements.

To simplify the selection process, it is worth using a table. It indicates the correspondence between belts and models of equipment.

Dimensions of belts for walk-behind tractor OKA

Since the transmission is one of the key elements of the drive mechanism, the choice and correct tension of the belt directly affect the operation of the entire device. Attention should be paid to the dimensions of the belt, namely the length and width. They must be selected individually for individual modifications.

To determine the required dimensions, the following data must be taken into account:

- A-1180 VN І GOST 1284.1-89, A-1213 І GOST 1284.2-89 - for forward travel;

- Z(0) 1400 I, Z(0) 1400 VN I GOST 1284.1-89 - for reverse.

When purchasing a product, it is also important to pay attention to the appearance of the strap. It must be solid, without unnecessary bends, defects and other damage, so as not to damage the cultivator of the walk-behind tractor.

Sizes of belts for Neva walk-behind tractors

During the selection of drive belts, special attention should be paid to their dimensions. You can use the table provided to determine the part you need.

First, it is worth measuring the distance from the pulleys to the rollers, a new element will be mounted to them. This will allow you to choose more accurate dimensions of the belt.

Tensioning the belt of the Neva walk-behind tractor: an algorithm of actions

The Neva MB-2 and MB-1 walk-behind tractor is characterized by a different arrangement of belts.

Therefore, the installation scheme of parts will be different. The belt tension on the MB-1 model is performed in a certain way:

- Initially, the casing is removed from the V-belt mechanism;

- Carefully remove the rear bar from the pulley;

- The key loosens the spring-loaded roller;

- The old element is dismantled and a new one can be installed;

- Pre-dismantled spare parts of the unit are installed.

It is worth considering how to replace the belt for units of the MB-1 model range:

- The shield and casing of the V-belt system are removed;

- The pulley bolt is loosened and the reverse belt is removed;

- The bolts that secure the bracket are loosened;

- The forward drive belt is removed;

- New elements are installed and tightened, everything is fixed and previously removed parts are returned to their place.

Adjusting the belt on the Neva MB-2 walk-behind tractor is as follows:

- The casing is removed;

- The screw loosens the tension of the standard belt;

- All screws holding the bracket to the unit body are removed;

- The old part is pulled out and the pulleys are adjusted;

- Before putting the belt, the places between the elements are thoroughly wiped, the hoses are blown;

- A new belt is installed. One end is connected to the gearbox shaft, the other - to the pulley located in the motor;

- The structure can be completely restored.

For more details on how to tighten the belt on the Neva walk-behind tractor, you should learn from the proposed video.

Basically, a new element is pulled when the walk-behind tractor breaks down. Much less often, replacement is carried out in advance to prevent malfunctions during operation of the unit. In any case, it is necessary to carry out work on replacing the belt carefully, since if it is overstretched, it will inevitably break.

Replacing the forward and reverse belts

Replacing the belt of the OKA walk-behind tractor is carried out without the use of technical devices by releasing the clamping mechanism, so this action can be carried out with your own hands, without the involvement of technical specialists. The main thing is attentiveness and accuracy when working. An important nuance is the use of identical parts of the drive mechanism.

The belt installation scheme is as follows:

- First you need to remove the reverse belt. We release the bolt of the drive pulley and tighten the spare part in the direction from the lever.

- We unscrew the two bolts from the bracket, remove the limit pins and remove the forward drive belt.

- We put new belts in place of the old ones in accordance with the direction of the forward pulley and reverse pulley, after which we tighten the bolt of the drive pulley and bracket.

- To assess the correct placement of the belts on the walk-behind tractor, it is necessary to release the clutch lever. If they sag in this position, then all of the above actions were performed successfully. Otherwise, it is necessary to adjust the position of the belt drive until it is in the correct position.