Having your own household means providing yourself with healthy food. However, every farmer knows how much effort and time such work requires. Health as a result will not thank you. We live in an age of technological progress, which means that there are many devices and developments on the market that make life much easier for us in various fields of activity, including farming.

Everyone who has a large plot of land knows about motoblocks and motor cultivators. This equipment allows you to perform all types of work - from cultivating beds to sowing plants. There is a large selection of different models on sale, but we will focus on only one of them, namely the walk-behind tractor from the Neva trademark. If you want to know everything about this unit, how to upgrade it yourself, about the instruction manual, then you will definitely like this article.

Review of Brenda Neva walk-behind tractors. Line of models, brand advantages

The history of the emergence of the brand "Neva"

CJSC Krasny Oktyabr-Neva is a well-known Russian manufacturer of small-sized agricultural machinery.

CJSC KO-Neva is a subsidiary of the well-known St. Petersburg aircraft manufacturer SPB OAO Krasny Oktyabr, which was founded in 1891. Under the Neva brand, a huge range of equipment for agricultural work is sold on the Russian, Ukrainian and Belarusian markets. Models of motoblocks and motor cultivators of this manufacturer are widely known in Kazakhstan, Uzbekistan, Moldova, Bulgaria, Armenia and the Baltic countries. The partners are American and Japanese companies, in particular, Briggs & Stratton, Honda, FHI Ltd (Subaru trademark), Lifan. The engines produced by these companies are used by various types of Neva walk-behind tractors and motor cultivators.

The quality certificate assigned to the products is ISO 9001:2008. All equipment manufactured at the plant meets European CE safety requirements.

Overview of the line of models and engines used in the Neva walk-behind tractors

Motoblock "NEVA" MB2 "MultiAGRO"

Motoblock MB2-B MultiAGRO (I/C 6.5)

Diesel walk-behind tractor "Neva" MB 23-SD27

Motoblock "Neva" MB1C-6.0

Motoblock "Neva" MB1B-6,0FS

Motoblock "Neva" MB1-N MultiAGRO (GP200)

Motoblock "Neva" MB1-B MultiAGRO (RS950)

Motoblock "Neva" MB 2B-6,5RS

Diesel walk-behind tractor "Neva" MB 23-SD27

Motoblock "Neva" MB23-H9.0 PRO

Motoblock "Neva" MB 23B-10.0

Petrol Motoblock "Neva" MB 23S-9,0PRO

Motoblock Neva MB-Compact MB-S6,0

Motoblocks "Neva" are produced in various modifications. Models available for purchase:

- a line of motoblocks "Neva" with a classic gearbox (MB-compact, MB-2, MB-23, MB-23SD with various modifications);

- the Neva line with the Multiagro gearbox, the plant's own patented development (MB-1, MB-2, MB-3 in several modifications).

Types of engines used in the model range of Neva walk-behind tractors:

- diesel;

- gasoline.

The manufacturer installs engines of the following manufacturers on these models:

- Briggs & Stratton (USA, Vanguard engine);

- Honda (Japan);

- FHI Ltd (Subaru trademark, Japan);

- Lifan (Lifan Industry Group, China).

Top models and engines of the Neva brand

The most popular model in Russia and Ukraine is the Neva MB-2, as well as all its modifications (MB2B-6.0FS, MB 2S-6.5PRO, MB 2S-7.5PRO, MB2 GX-200, MB2 B-6.5RS) .

MB-2 belongs to a number of motor blocks of the middle class. It is readily acquired by farmers who own garden plots, farms and utilities of medium and small area.

Features of MB-2: versatility, transmission is selected in such a way that the walk-behind tractor easily performs any agricultural and agricultural work in areas up to 20 acres and even more. MB-2 can reach speeds up to 12 km/h!

The speed range is adjustable, while the speed of movement can be easily reduced to 2 km / h. Therefore, using the MB-2, you can transport goods around the site, clean the area from leaves or snow, collect hay in a trailer or cart, and also work directly on the ground.

An interesting feature of the MB-2 is the engine. The unit can be purchased both with a domestic DM-1K engine (6.2 hp) and with engines from foreign manufacturers of automotive equipment, for example, from Robin-Subaru, Briggs & Stratton, Tecumseh. The manufacturer on its official website notifies that in the future, new modifications of already known walk-behind tractors will be presented to the attention of buyers.

If desired, in combination with walk-behind tractors, you can use mounted and trailed equipment manufactured by Russian and other manufacturers whose equipment is aggregated with this walk-behind tractor. The most common trailer equipment: trailer, cart, plow, hiller, potato planter, snow plow, harrow, rippers.

Known not only thanks to motoblocks. Motor cultivators are also very popular - more compact and less heavy equipment, using which it is possible to cultivate suburban areas up to 10 acres. One of the leading models, leading in popularity, is the MK-200 motor cultivator. The unit is produced in three modifications (MK200-B5.0RS, MK200-H5.0, MK200-S6.0).

Each modification runs on an engine from different manufacturers - Honda, Subaru or Briggs & Stratton. If we compare their weight with walk-behind tractors, then walk-behind tractors are, of course, almost twice as light. The only downside can be that they cannot process a large area without frequent breaks.

The engines installed on these units, with proper observance of the rules of operation and timely maintenance, will work for many years and delight their owners with high productivity and reliability. You can also install the engine yourself - after purchase, if you want to replace it with another, more powerful one, as well as after engine wear and the need for an unscheduled change.

On the Internet, it is easy to find a video of how such an installation is carried out / For example:

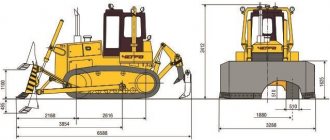

Below is the Neva Motoblock - a photo of the MB-23 model.

Motoblock "Neva" MB 23B-10.0

Design

Hole cutters made of different materials and with different coatings practically do not differ in their structure. They consist of a cartridge (a means of fastening through which the working part - the crown - is connected to the drill itself), the crown itself (a kind of bowl, on the edge of which characteristic elements are located) and a drill. The drill is selected according to the material with which you will work. Insert box

The process is carried out using a perforator and crown assembly. You may also need a chisel and a hammer - for tamping some elements. After that, you need to mark the room, checking the height of future sockets (taken from the project) and switches. The drilling height for switches is 80-100 cm, and for sockets - 40 cm. These standards are not prescribed anywhere, except for the distance from the nearest source of electricity to the water supply elements. Any action with solid materials (stone) is accompanied by a copious amount of dust generated, so it is worth using goggles and a respirator. When working in residential premises, it is better to close up all interior cracks, close the doors.

The main thing is not to put much pressure on the puncher, not to tilt it. This may jam it and damage the cutter. If you have a small power tool, then you need to mark the circle (by drilling a little), and then drill (with a conventional drill) along the contour of the circle. This will significantly speed up the process.

For these purposes, a drill for 7-8 is suitable. When you have reached the required depth, you need to take a chisel and a hammer and clean the hole from the remnants of the material.

Benefits of the brand "Neva"

Neva brand products have several significant advantages in comparison with foreign agricultural machinery:

- the possibility of a quick purchase (no need to wait for delivery under the order from abroad);

- a wide range of models operating on different types of fuel;

- a wide range of modifications (each is unique!);

- availability of maintenance stations in each country where Neva walk-behind tractors or cultivators are used;

- the possibility of acquiring the necessary spare parts or consumables for the maintenance of the walk-behind tractor;

- simple and understandable instructions in Russian;

- stable operation of the walk-behind tractor, subject to the rules of operation (with careful handling, you can use this unit for many years ");

- moderate fuel consumption;

- powerful gearboxes (classic or Multiagro);

- affordable price;

- extensive experience of the owners: you can always read reviews of real customers and find out what the Neva walk-behind tractor is at work. Break-in videos, engine disassembly and other key usage points can also always be found on the Internet;

- if necessary, you can put a new engine on the walk-behind tractor to replace the old one, and continue efficient work.

Application

According to the operating instructions, before turning on the walk-behind tractor, it is necessary to carry out preparatory work:

- check all components and fasteners for tightness and reliability;

- familiarize yourself with the safety measures described in the manual;

- check the oil level in the engine;

- fill the fuel tank with clean gasoline AI-95 or AI-92;

- to re-preserve the walk-behind tractor;

- check the presence of oil in the gearbox;

- inspect tires.

Running in

Running in is an important stage in the operation of any technique. If the process is carried out incorrectly and the walk-behind tractor is illiterately maintained, its service life is reduced, the mechanisms fail.

The depth of soil processing reaches no more than 10 cm. Experts recommend that this process be carried out without loads.

After running in, you must do the following:

- make the first oil change;

- check the strength of fasteners;

- adjust the belt for the walk-behind tractor;

- check the operation of the left wheel disengagement;

- remove additional restrictive gaskets between the carburetor outlet flange and the nozzle flange.

See » Veim's most popular walk-behind tractors

cultivation

When operating a walk-behind tractor with a cultivator, it is necessary to adhere to the following algorithm:

- Install the equipment in a horizontal position, check the steering.

- Set tillage limiter to desired depth.

- Cultivate with the carburetor throttle half closed.

- When working at low temperatures, if the walk-behind tractor does not start, use the following method:

- soak the equipment for about 10 hours in a warm room, then turn it on quickly;

- fill the engine with oil with a temperature of + 50 ... 60 ° С;

- warm up the carburetor nozzle and the system itself by laying a rag soaked in hot water on them.

Comparison of Neva walk-behind tractors with other brands

Neva or Oka?

Reviews of the Neva walk-behind tractors in comparison with the Oka brand are quite critical. For example, some owners claim that Oka is the most inexpensive analogue. Of the advantages of the Oka walk-behind tractors, cheapness is noted, but the Neva has an advantage on the side of powerful and reliable American, Japanese, and Chinese engines.

Of the minuses of the Oka walk-behind tractors, there are:

- frequent overweight to the side due to the high center of gravity;

- heavy weight (not suitable for a female operator);

- rapid wear of drive belts.

So, the Neva or Oka walk-behind tractor - which is better? It's up to the buyer to decide, of course. Before buying, you need to not only choose the desired walk-behind tractor, but also proceed from the cost and practical benefits - the size of the site, the capabilities of the unit, and personal skills. With proper operation, any walk-behind tractor will be useful and bring maximum results.

Neva or Salut?

Salut, according to the farmers who bought this unit, is a cheaper analogue of the Neva walk-behind tractor. We have collected the most common disadvantages of Salyut walk-behind tractors, according to reviews on farm forums:

- factory wheels fly off factory mounts with strong vibration;

- problem starting the engine in the cold (you have to warm the engine for a long time, which increases fuel consumption);

- sometimes slips on virgin soil.

"Neva" deserves reviews with a minus less often, however, in comparison with the Salyut walk-behind tractors, some owners do not give it a very high rating. The utility of a walk-behind tractor can be individual - depending on the type of land, the size of the plot, the strength of the operator and the technical skills of operating the walk-behind tractor.

Neva or Ugra?

Motoblock "Ugra" is another domestic agrotechnical device that works with soils of varying complexity. In comparison with the Neva, the Ugra units will hardly cost more, some used models can be purchased at quite reasonable prices: within 15-35 thousand rubles (5-15 thousand hryvnias), new ones will cost 3 times more - from 30 to 50 thousand rubles (10-30 thousand hryvnias).

The main disadvantages of "Ugra":

- some models do not have an additional set of cultivators (you need to buy separately);

- intense vibration feedback to the steering wheel;

- small volume of fuel tank;

- abrupt inclusion, there is no smoothness, starts from a place with a jerk.

Neva or Agate?

The Agat motoblock is a Russian-made technical unit, produced since 2002.

Like the Neva, they are equipped with domestic and foreign engines made in the USA, China, and Japan.

Cons of "Agatha", according to farmers (reviews from the forums):

- low wheel height compared to the Neva;

- when installing the trolley, the speed of the walk-behind tractor is very low;

- some modifications are seen in oil leakage (weak seals);

- the need to stretch the starter cord almost to its entire length to start the walk-behind tractor.

In this video you can see the comparison of three types of walk-behind tractors, including "Neva" and "Oka"

Attachment

In order to keep up with competitors, the manufacturer has equipped its model with various devices. The design of the Neva MB 1 is so versatile that it supports any equipment. It all depends on the preferences of the owner. Consider the most common options:

- Milling cutters - necessary for cultivating the soil. The design of the walk-behind tractor provides for eight cutters, although the basic version has four. Additional kit sold separately.

- A plow or a hitch - they usually buy metal wheels and a grouser with them. These devices provide reliable traction with the soil, and thereby compensate for the shortcomings of the small mass of the walk-behind tractor.

- Potato planter - there are different models: KS-1, KS-1A and KST. This product is designed to facilitate the planting process and create favorable conditions for harvesting. Together with the potato planter, an even planting and a fixed row spacing are ensured, and the productivity of the planter itself is in the range of 0.2-025 ha per hour. The equipment is designed for a distance between tubers of 25-30 cm, while the row width can be adjusted up to 70 cm.

There are two types of potato planters:

- Fan. A feature of such diggers is an all-metal knife at the base. Metal rods fan out from it. The knife is used to lift the earth with a layer, and the layer itself is sifted through the rods. Root crops, in turn, linger and rise to the surface. The fan digger has a capacity of 0.15 hectares per hour.

- Vibrating. Such potato diggers have several advantages compared to fan analogues. First, they have many more different devices for more efficient work. For example, there is a plowshare and a vibrating grate designed for sifting the soil. The duties of the plowshare include raising the soil along with the root crops, and laying it out on the grate. The main task of this grate is to sift the earth in such a way that clean potatoes remain on the surface of the grate. As experience shows, diggers KKM-1, KMU-3, KK-6 and others are better suited for the Neva MB 1 walk-behind tractor. This equipment has a capacity of about 0.2 hectares per hour.

Please note that mowers are also divided into several types:

- Segmental - have shearing knives made of hardened steel. The blades move in a horizontal plane and therefore work best on flat surfaces. For example, this type of equipment can be recommended for working with cereals and evenly standing shrubs. As an option, there is a KN-1.1 mower with a cutting width of 110 cm and a capacity of 0.35 ha/hour.

- Rotary type - such mowers are becoming more and more popular, as they are in no way inferior to their segment counterparts, and in some ways even surpass them. High-strength knives act as working elements of rotary mowers. They are planted on discs and rotate at an incredible speed. This allows you to process not only small shrubs, but also dense grass. Vivid examples of this family are Zarya and Neva KR-05. Both mowers are produced in Kaluga.

It is noteworthy that the SMB-1 snow blower of the auger type was developed specifically for the Neva MB 1 walk-behind tractor. Its principle of operation is extremely simple and effective - the auger functions in such a way that the snow from the edges is pushed into the middle, that is, towards the nozzle. The choice of the snow ejection direction sets the snow blower's swivel screen, and using the skids on the body, you can adjust the cleaning height. Rotary brush - designed exclusively for cleaning debris. Its working width is 90 cm, and the installation angle reaches 90 degrees. The communal rotary brush has a capacity of 2200 sq. m.

Another attachment is a cart trailer with a maximum load capacity of 40 kg. The cart is equipped with a driver's seat, as well as durable brakes and a brake hitch as standard.

The main disadvantages and "diseases" of the Neva walk-behind tractors

Without the disadvantages, the advantages would not be so noticeable. Let's look at the main disadvantages and "diseases" of the Neva walk-behind tractors.

So, what do owners of Neva walk-behind tractors most often complain about after a purchase?

- not everyone is satisfied with the price (according to reviews, some buyers risk buying used equipment in order to save on a new walk-behind tractor);

- without a weighting agent, some models “jump” while working on the ground, but the problem is solvable - just hang a weighting agent on the walk-behind tractor. The weight of weights sold by manufacturers of attachments starts from 10 kg and above;

- the heavy weight of certain Neva models makes them not very manoeuvrable. However, the large weight of the unit can be an advantage if used correctly;

- the walk-behind tractor may not start on the ground with a slope of more than 15 degrees, so it is always recommended to start work on the most even, horizontal surface;

- the size of walk-behind tractors is mostly compact, but there are also rather bulky models that do not fit in the trunk of a car;

- feedback from farmers on the most common technical shortcomings: rapid wear of the drive belt, gearbox noise, tying cutters in virgin soil, plowing the land in “waves”, erasing clutch cables and the need to replace them with new ones.