Headlight for walk-behind tractor - self-production

Many owners of walk-behind tractors use headlights from domestic and imported cars to install on their units. This method is the simplest, but it should be remembered that the old headlight on the walk-behind tractor will not emit bright enough light and will last no more than a few months.

It is much better to make lighting for an agricultural machine with your own hands. This does not require the purchase of expensive materials and equipment. You will need the same old headlight, the stuffing of which you will later replace with new parts.

The order of work is as follows:

- Remove the existing glass surface and other elements from the old headlight that are attached to the base with plastic clips;

- Next, make a plaster cast based on the headlight frame. To this end, pour the still liquid material into the base of the headlight around its entire perimeter. After the final drying of the gypsum mass, it must be carefully removed;

- Apply 3 layers of fiberglass to the impression. Between each of the tiers should be a layer of epoxy. Place the blank in vacuum conditions and wait at least a day - during this time the cast will completely harden. After that, align the workpiece so that even the slightest chips do not remain on it;

- Start making glass for your homemade headlight. To do this, preheat the oven to 190 ° C, make a stand of 8 rails fastened together and fix a sheet of fiberglass in it. Before putting the mold in the oven, do not forget to remove the protective film from the material, otherwise it will be covered with dust particles;

- As soon as the material sags in the stand, take it out of the oven and apply it to the workpiece made earlier. The product must be placed and kept under full vacuum until it hardens.

After hardening, the manufactured headlight will need to be carefully sanded, degreased and dried. Then 1-2 halogen lamps or LED strip are placed inside it. The installation of the headlight on the walk-behind tractor is carried out after a thorough check of the lighting device. To put the headlight on the walk-behind tractor, be sure to use a reliable frame and at least 4 fasteners.

DIY

Almost all owners of motoblocks resort to using headlights from Soviet passenger vehicles as lighting equipment. This is one of the easiest ways to solve the problem.

But do not forget that such light will not be bright enough, and it is unlikely to please you with a long service life.

Therefore, the best option is considered to be the independent manufacture of such electrical equipment. You do not need to purchase expensive sources and equipment. All you need is the same headlight from a Soviet car. You will only replace the inside.

So, for starters, the outer glass and other elements fixed with plastic clips are removed from the headlight. The next step is to make a dummy body of the lighting fixture. It is made from plaster. Liquid gypsum is poured into the base of the lighting fixture and evenly distributed throughout the base. Wait until the plaster is completely dry, then the cast must be carefully pulled out.

Please note that experts do not recommend artificial drying, so it is better to wait for the natural hardening of the gypsum.

This template needs to be coated with fiberglass in three layers. Be sure to apply epoxy between coats. It is inexpensive, on the market its price fluctuates around 400 rubles.

Connecting the headlight to the motoblock generator

Installing a light on a walk-behind tractor with your own hands is quite simple if you use a regular electric generator of an agricultural machine for this. Especially for this, many manufacturers of equipment produce walk-behind tractors with generators, the power reserve of which is slightly increased especially for lighting installation. Thus, the power of the node is quite sufficient for uninterrupted power supply of lighting devices and sound signal.

To install the headlights on the walk-behind tractor, and connect them to the generator, you need to proceed in this order:

- Connect the generator with a wire to the switch, which must be fixed near the steering wheel or in another place convenient for the operator;

- Separate the wiring from the switch and connect it to the headlight, then check the operation of the lighting device;

- Then disconnect the wires and place them in a tight corrugation that protects the wiring from moisture and mechanical damage.

If the alternator has sufficient power reserve, the headlight will shine uninterruptedly and brightly. If the power of the unit is insufficient, then the headlight will flash every time the engine goes into low speed operation. In this case, it is best to change the regular motoblock generator to a unit from MTZ tractors. It should be remembered that for the installation of a new generator in the construction of a walk-behind tractor, additional support frames will need to be welded, and a lighting coil must be used to connect the assembly. After connecting, regularly check the integrity of the wiring contacts, otherwise if moisture gets on them, a short circuit may occur in the power supply of the walk-behind tractor.

How to conduct lighting on motorcycles from a generator?

It is easiest to make light on a walk-behind tractor with your own hands from a “native” electric generator. If the manufacturer provides for such an opportunity, then the installed generator has a certain power reserve. It will be enough for the normal functioning of the key electrical appliances of the walk-behind tractor and power supply for additionally installed electrical equipment (turn signals, headlights, sound signal).

The algorithm for connecting light from an installed electric generator does not differ in complexity:

- Connect the power generating device to the switch on the steering column using a wire;

- From the switch, separate the wire system to electrical equipment (on a walk-behind tractor this is a headlight);

- Place the wires in the corrugation to protect them from mechanical damage. So they will not hang out and interfere when working on the unit.

If the generator is with a high enough power level, then the lighting will be good. When the light goes out at low speeds, it is necessary to change the installed electric generator to a device from a tractor or machine.

You can install a generator from Zaporozhets. The device is small in size, so it is easy to fit in the area between the motor and gearbox. Installation is easy. Fasteners are pre-made to fasten the generator and fix it on the frame: strong metal rails are welded to the frame, after which the clamp is attached.

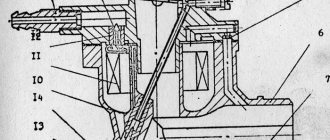

The presented diagram will help you figure out the correct attachment of the device to the walk-behind tractor.

An electric generator from an old or new car is capable of providing normal lighting for a walk-behind tractor. It is also possible to solve other problems with the connection of various electrical equipment.

How to make light on a walk-behind tractor without a generator?

There is another way that allows you to connect the light on a walk-behind tractor without a generator. It will need a 12-volt battery and LED strip. It is not necessary to buy a new battery - an old gel cell from an electric scooter is quite suitable for work.

In addition to materials, you will need to decide in advance on the place of installation of the battery. Since it has small dimensions, it is best to place it between the motor and the gearbox of the walk-behind tractor. The next work plan is as follows:

- From a steel corner, make a mount that will match the size of the battery used;

- Position and fix the mount on the frame of the unit;

- Install the battery inside the mount, fix it with a steel plate and two bolts;

- From the battery to the switch and headlight, lay the wiring. Fix the connection points with soldering and insulate with tape. The video will help you to get acquainted with the connection of the headlight on a walk-behind tractor without a generator in more detail.

The light of a battery-powered headlight is quite intense and bright.

However, this method has one significant disadvantage - the battery capacity will last no more than a few hours of continuous operation, after which the power source will need to be charged. In this case, you can make the light on the walk-behind tractor from the ignition. To do this, one end of the wiring must be connected to the ignition system of the unit, the other end to the switch, and from it to the headlight. A lighting device connected in this way will only work when the ignition of the walk-behind tractor is on.

All of the above methods of manufacturing and connecting the headlight are suitable for Neva, MTZ motoblocks and agricultural machines produced by other domestic and foreign manufacturers.

How to make a headlight on a walk-behind tractor with your own hands

Not all motoblocks Neva, Bison, Centaur and others include a headlight. Therefore, owners who want to make light on them decide for themselves what to do: buy a factory kit with a ready-made lighting system, use a flashlight from faulty equipment, for example, a moped, a light motorcycle, or make a budget version with their own hands.

If you decide that your unit will have a headlight made by your own hands, then the case from the burned-out “housekeeper” will fit perfectly for this purpose. You will also need to stock up on a small piece of electrical wire, a toggle switch (switch) or a simple switch.

The headlight is connected to the agricultural unit very simply:

- First, the toggle switch (switch) is fixed. It is placed in the most convenient and fairly reliable place, for example, on the steering rod of a walk-behind tractor next to the gear lever.

- Then the headlight is fixed. This can be done in a specially designated place provided by the manufacturer (usually, such a “place” is located in front of the engine) or on the steering column. When a stationary headlight is placed in front of the engine, it quickly gets dirty, and the light from it spreads only along the bottom. For this option, it is better to use a lamp moving in several planes, then you can direct the light in the right direction yourself.

- Next is the wire. It is more convenient to do this from the nearest power source, for example, a 12-volt oil pressure warning lamp located on the steering column of the walk-behind tractor.

- A wire from the power source is connected to the switch, and a cord is pulled from it to the place where the headlight is located. All wires are neatly wrapped to the steering stem with insulating tape or secured with special clamps.

You can use halogen lamps to illuminate your agricultural unit, but they quickly heat up and fail. It is better to make lighting with 5W LED light sources with a small scattering angle, which will save energy, shine brightly and far away.

As you can see, it’s absolutely not difficult to make a headlight on a walk-behind tractor with your own hands. And it will be able to work no worse than the “car dealership” and illuminate your path when you return home along a dark road.