The choice of engine for the motor-block "Cascade"

Motoblocks "Cascade" are common technical means and are used to perform various jobs. The popularity is due to the fact that manufacturers have equipped these units with the necessary functions and characteristics, which allows it to be used in almost all cases of life, as well as for cultivating land.

Many owners appreciate this technique because of its affordable cost, compactness and high performance.

What engine can be put on the Cascade walk-behind tractor?

As standard, the units are accompanied by domestically produced engines DM-66 and DM-68.

But often a long service life leads to the need to replace the "heart" of the walk-behind tractor. The problem of engine selection is also relevant because Russian engines of this plan are no longer produced. As a result, there is an interest in suitable devices of foreign origin.

The most popular is the Briggs & Stratton I/C engine which is known for its excellent machine compatibility and more power (7 hp). The advantages of the choice include a reinforced transmission and the possibility of a deeper immersion of the cutter during soil processing. Another fairly common replacement for the native Cascade engine is the American-made Briggs & Stratton Vanguard OHV. The model is known for its incredible power (7.5 hp), so it is suitable for owners of large areas with heavy soil. The Lifan 168 F-2 variant is also quite good. Engine displacement is 196 cm 3. The development belongs to the class of gasoline four-stroke models, known for their practical properties (power - 6.5 hp). Air cooling will allow you to work continuously for quite a long time. Subaru EX17 also managed to win recognition among domestic users and show itself only in the best light. Contains 6 liters. With. and is distinguished by a horizontal crankshaft.

Read also Cabbage and Korean carrot salad recipe

Naturally, a lot depends on the wishes of the owner of the Cascade walk-behind tractor, its financial capabilities and the specifics of the machine itself. In order to figure out what's what, you need to get acquainted with the current series of the brand and learn about their technical characteristics.

Design features

Motoblocks "Cascade" have 4 main components for control and movement. This:

The chassis consists of a frame and drive wheels. There are also additional nodes with the help of which torque is transmitted from the motor to the wheels. The unit is equipped with powerful wheels with large treads, which allows the device to be used even on heavy soils.

The transmission is reliable and transmits torque from the engine to the wheels, being an integral part of the rotation of the unit. The torque is transmitted using gearboxes and a chain, and the box itself has four speeds and is installed in a special block on the frame. A large number of models also have reverse speed , which allows you to increase the maneuverability of the device.

The control is carried out by the clutch handle, with which you can adjust the throttle on the carburetor, adding or decreasing engine speed. Also, with the help of the clutch handle, the wheels are blocked when it is necessary to turn in one direction or another. The steering wheel can be adjusted to the height and other parameters of the user.

Thanks to all these points, it is easy and simple to operate the walk-behind tractor even during long work on the site.

In order for the machine to work smoothly throughout the entire period of use, it is necessary to run in after purchase and constantly add fresh oil to the box and motor.

Filling in quality fuel is also important. If you do not follow these rules, then over time the device may fail and become unusable.

Source

Video: Installing a Chinese Engine on a Motoblock Cascade

Lifan 168

One of the most widely used engines. Lifan 168. It has an engine capacity of 196 cubic centimeters and runs on gasoline. Power. 7 horsepower, air-cooled, so they can only run for a short time.

To ensure the life of the Lifan engine, after installing the Chinese engine, it is necessary to constantly fill in fresh oil and carry out maintenance.

The installation of the motor is simple and does not require alteration of the mounting on the frame.

Fluid replacement work is carried out as follows:

- with the engine turned off, unscrew the drain plug located on the pallet;

- drain the oil from the system;

- tighten the stopper;

- add new oil;

- warm up the engine;

- check the level and top up if necessary.

B&S I/C

Engine B can also be installed.&S I / C, related to modern models and popular in everyday life. They are often used on cascaded units.

This is due to the following features of the engine:

- 7 horsepower;

- reinforced transmission;

- enlarged combustion chamber;

- minimal noise during operation;

- high functionality even at low temperatures.

Vanguard ov

The imported Vanguard OHV engine is also one of the powerful engines that can be installed on this manufacturer's walk-behind tractor and can perform all the necessary tasks. This engine has 7 horsepower.

One refueling is enough to work without interruption for 4-5 hours.

Subaru EX17

You can put the Subaru EX17 engine, which is popular among owners of Cascade walk-behind tractors. It turned out great. It has a special camshaft design inside and a large shaft diameter to increase engine power and efficiency.

As you can see, quite a lot of motors can be installed on the Cascade motor block at the moment. Choosing the right model depends not only on its functionality, but also on the financial capabilities of the owner.

It is recommended to purchase a motor according to the specific use of the machine to ensure its durability. Therefore, before buying, you need to understand the characteristics of the engine, consult with experts and buy the best model.

It is also worth paying attention to the configuration, build quality and other points that are familiar to any motorist. If you do not have the skills, you should always seek help from specialists

The engine must meet all the requirements that will allow it to work efficiently and increase its service life.

The main problems of motors

Among the main failures of Cascade walk-behind tractors:

- The engine will not start;

- engine runs intermittently.

The reasons for such malfunctions can be very different. from low-quality fuel to lit candles. Battery drain can also be the cause. In this case, charge the battery and clean the fuel line or spark plug and replace it completely if necessary.

Another malfunction could be the loss of the engine. The main reason in this case is clogging of the carburetor or filter, which prevents the required amount of fuel from entering the combustion chamber. In this case, it is recommended to clean the system, since a return is possible when the engine is started.

Experts recommend periodically servicing this equipment to avoid such problems.

All of the above failures are quite rare, and if necessary, you can fix them yourself, no special knowledge is required. If you have maintenance or repair problems, you can consult a specialist or get instructions on how to use the network.

Attachments

To increase the functionality of the Cascade walk-behind tractor, the manufacturer installs mounts on it, with which you can perform various operations.

Among the most common pendants:

Engine installation kit for walk-behind tractor

The installation kit is used to install an imported engine on a domestic walk-behind tractor (transmission) MB-1, Oka, Neva, Cascade, Favorit, Luch and structurally similar to them.

The kit includes a pulley, a platform (plate), a belt guide, a set of fasteners.

When ordering an installation kit, please specify the information we need for the correct configuration of the kit suitable specifically for your engine, namely:

- The model of the walk-behind tractor on which your new engine will be installed, for us to determine the type of pulley.

- The model of the engine itself for which you want to purchase the installation kit.

- The diameter of the output shaft of this engine (19 mm., 20 mm., or another) is necessary to select the correct pulley for the diameter.

- The type of thread from the end of this output shaft is simple metric or inch (you can check by trying to screw in a simple bolt by 8, if it doesn’t go, then the thread is inch).

- The thread type of the two holes above and below the output shaft required to install the belt guide bracket (can be checked with the same bolt)

Given this information, the installation kit you need will be completed.

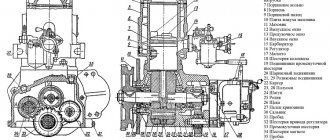

Scheme of installing an imported engine on a walk-behind tractor

Figure 1 - installation of an imported engine on a walk-behind tractor using a platform (plate). Front view of the walk-behind tractor.

| Position | Name |

| 1 | Engine |

| 2 | Playground (slab) |

| 3 | plank |

| 4 | Nut M8 |

| 5 | Washer 8 65G |

| 6 | Washer A 8.01.016 |

| 7 | Bolt M8 25 |

| 8 | Bolt M8 40 |

Figure 2 - installation of a pulley and a belt damper on an imported engine. View from the side of the output shaft of the engine.

Source

Installing a lifan engine on a cascade walk-behind tractor

The installation kit is used to install an imported engine on a domestic walk-behind tractor (transmission) MB-1, Oka, Neva, Cascade, Favorit, Luch and structurally similar to them.

The kit includes a pulley, a platform (plate), a belt guide, a set of fasteners.

When ordering an installation kit, please specify the information we need for the correct configuration of the kit suitable specifically for your engine, namely:

- The model of the walk-behind tractor on which your new engine will be installed, for us to determine the type of pulley.

- The model of the engine itself for which you want to purchase the installation kit.

- The diameter of the output shaft of this engine (19 mm., 20 mm., or another) is necessary to select the correct pulley for the diameter.

- The type of thread from the end of this output shaft is simple metric or inch (you can check by trying to screw in a simple bolt by 8, if it doesn’t go, then the thread is inch).

- The thread type of the two holes above and below the output shaft required to install the belt guide bracket (can be checked with the same bolt)

Engine Lifan Motoblock Beam

Lifan engines for walk-behind tractor: installation, characteristics. Chinese engine

Lifan for motoblock

Every self-respecting gardener, before the start of the summer season, digs up his site with a walk-behind tractor. But not everyone can afford to buy a new unit. Therefore, in summer, residents use cultivators made in the USSR. Such motor blocks often have engine problems, but there are many reasons for this. Basically, fault faults. This is a service life that has long passed. Recently, such problems have been solved by Lifan engines on a walk-behind tractor, because this is a profitable way to solve the problem on your own and for a long time.

Scheme of installing an imported engine on a walk-behind tractor

Figure 1 - installation of an imported engine on a walk-behind tractor using a platform (plate). Front view of the walk-behind tractor.

| Position | Name |

| 1 | Engine |

| 2 | Playground (slab) |

| 3 | plank |

| 4 | Nut M8 |

| 5 | Washer 8 65G |

| 6 | Washer A 8.01.016 |

| 7 | Bolt M8 25 |

| 8 | Bolt M8 40 |

Figure 2 - installation of a pulley and a belt damper on an imported engine. View from the side of the output shaft of the engine.

Motoblocks "Cascade" are common technical means and are used to perform various jobs. The popularity is due to the fact that manufacturers have equipped these units with the necessary functions and characteristics, which allows it to be used in almost all cases of life, as well as for cultivating land.

Many owners appreciate this technique because of its affordable cost, compactness and high performance.

Specifications and prices for engines

Motoblock Oka

Motoblock Oka with a Lifan engine has a power take-off shaft, which allows you to aggregate the device with various attachments, which must be purchased separately.

Motoblock Oka

The design of the Oka walk-behind tractor provides for a fairly heavy frame, which allows the unit to be used on the most difficult areas of soil.

Specifications:

- total weight - 95 kg;

- digging depth - 35 cm;

- width of the processed strip - 60 cm;

- load capacity - up to 400 kg;

- maximum speed - 9 km / h;

- unit length - 150 cm;

- unit width - 60 cm;

- unit height - 105 cm;

- fuel tank capacity - 3.6 l;

- fuel consumption - 1.5 liters per hour of work.

The Oka walk-behind tractor uses the Lifan 168F-2 engine, which is considered the most powerful in its line. It comes with a manual starter and a reduction gear.

Lifan 168F-2

Engine Features:

- compact dimensions;

- unpretentiousness in the fuel used;

- the cylinder liner is made of cast iron, which can significantly increase reliability;

- ignition system without transistor;

- slight vibration during operation;

- a system that prevents the engine from starting if there is not enough oil in it.

- ease of use.

Specifications:

- engine size - 0.196 l;

- maximum power - 6.5 hp;

- rotation - 3600 rpm;

- motor weight - 15.3 kg;

- diameter - 6.8 cm.

For more information about the operation of the Lifan 168F-2 engine, see the video:

This Lifan engine for the Oka walk-behind tractor, the price of which is about 9 thousand rubles, has sufficiently powerful characteristics for use in relatively small areas.

Ural

Specifications:

- total weight - 120 kg;

- load capacity - up to 500 kg;

- maximum speed - 15 km / h;

- unit length - 156 cm;

- unit width - 79 cm;

- unit height - 105 cm;

- fuel tank capacity - 6 l;

- fuel consumption - 2 liters per hour of work.

Motoblock Ural with a Lifan engine is a rather unpretentious device that does not require frequent repair actions.

The Lifan 170F motor used in this walk-behind tractor can also be used in other units - Salut, Favorit, etc.

Specifications:

- type of motor used - 4-stroke, gasoline;

- number of cylinders - 1;

- engine size - 212 cm3;

- maximum power - 7 hp;

- rotation - 3600 rpm;

- motor weight - 20 kg;

- diameter - 6.8 cm;

- crankcase volume - 0.6 liters;

- fuel consumption - 394g / kWh;

- cooling type - air.

The cost of this engine is about 16 thousand rubles.

MTZ 09

The MTZ 09 motoblock, which has a 13 hp Lifan engine in its stock, is a technique manufactured at the Minsk Tractor Plant. The scope of its application for MTZ, Sadko, Don, Huter, Profi, Plowman, Champion, Carver, Husqvarna motoblocks is very extensive: grass mowing, harrowing, cultivation, plowing, inter-row cultivation, etc.

Specifications:

- total weight - 120 kg;

- load capacity - up to 650 kg;

- maximum speed - 11 km / h;

- unit length - 178 cm;

- unit width - 84 cm;

- unit height - 107 cm;

- gears - four forward and two back.

Motblok MTZ 09

The design of this walk-behind tractor is equipped with a Lifan 188FD engine equipped with an electric coil with a power of 7A, which allows you to connect various electrical equipment to it.

Advantages of this engine:

- the ability to start manually, as well as using an electric starter;

- fairly compact dimensions;

- electronic ignition.

Specifications:

- maximum power - 13 hp;

- cylinder diameter - 8.8 cm;

- engine size - 389 cm3;

- revolutions - 3600 rpm;

- start type - manual and with the help of an electric starter;

- fuel tank capacity - 6.5 l;

- fuel consumption - 374 g / kWh;

- unit length - 46.5 cm;

- unit width - 43.5 cm;

- unit height - 50 cm;

- total weight - 33 kg.

The cost of this engine will be about 25 thousand rubles.

Lifan Volga MK3-7L

Motoblock Lifan Volga MK3-7L has the following technical characteristics:

- width of the processed strip - up to 90 cm;

- digging depth - up to 20 cm;

- type of engine used - gasoline;

- motor power - 7 hp;

- start type - manual;

- fuel tank volume - 3.6 l;

- total weight - 78 kg;

- unit length - 138 cm;

- unit width - 65 cm;

- unit height - 97 cm.

Lifan Volga MKZ 7L

The cost of this unit is about 28 thousand rubles.

Cascade

Motoblock Cascade with a Lifan engine is used mainly for work in household plots, small gardens and orchards. Using special attachments, you can significantly expand the use of this walk-behind tractor, i.e. adapt it for mowing grass, transporting various goods, etc.

Specifications:

- unit length - 150 cm;

- unit width - 59 cm;

- unit height - 115 cm;

- total weight - 103 kg;

- maximum speed - 10 km / h;

- rotation - 3000 rpm;

- width of the processed strip - up to 93 cm;

- digging depth - up to 20 cm.

Motoblock Cascade

The Lifan ICE for the Cascade walk-behind tractor has the following technical data:

- type of motor used - 4-stroke;

- maximum power - 6 hp;

- cylinder diameter - 7.6 cm;

- engine size - 317 cm3;

- start type - manual.

To find out how to install the engine on the Cascade walk-behind tractor, just find this video on the Internet, which clearly shows the installation process.

Mole

The Lifan 160F engine on the Mole walk-behind tractor is quite popular, which is due to the fact that it shows a fairly high efficiency in operation. Although its power is relatively small, it is quite suitable for private use.

Specifications:

- maximum power - 4 hp;

- engine type - 4-stroke, gasoline;

- engine size - 120 cm3;

- start type - manual;

- fuel tank capacity - 2 l;

- fuel consumption - 360 g / kWh;

- total weight - 13 kg.

The cost of this motor on a Mole walk-behind tractor is about 7 thousand rubles.

Engines for Lifan motoblocks, the official website of which is located at www.lifan-moto.ru, are fairly reliable power units, thanks to which any equipment on which they are installed will show very high performance.

The popularity of these motors among summer residents also explains the fact that many people prefer to install engines of this brand on their walk-behind tractors.

Design features

Motoblocks "Cascade" have 4 main components for control and movement. This:

The chassis consists of a frame and drive wheels. There are also additional nodes with the help of which torque is transmitted from the motor to the wheels. The unit is equipped with powerful wheels with large treads, which allows the device to be used even on heavy soils.

The transmission is reliable and transmits torque from the engine to the wheels, being an integral part of the rotation of the unit. The torque is transmitted using gearboxes and a chain, and the box itself has four speeds and is installed in a special block on the frame. A large number of models also have reverse speed , which allows you to increase the maneuverability of the device.

The control is carried out by the clutch handle, with which you can adjust the throttle on the carburetor, adding or decreasing engine speed. Also, with the help of the clutch handle, the wheels are blocked when it is necessary to turn in one direction or another. The steering wheel can be adjusted to the height and other parameters of the user.

Thanks to all these points, it is easy and simple to operate the walk-behind tractor even during long work on the site.

In order for the machine to work smoothly throughout the entire period of use, it is necessary to run in after purchase and constantly add fresh oil to the box and motor.

Filling in quality fuel is also important. If you do not follow these rules, then over time the device may fail and become unusable.

Lifan engines for walk-behind tractor: installation, properties. Chinese Lifan engine for walk-behind tractor

Before the beginning of summer, any competent summer resident digs up his own plot with a walk-behind tractor. However, a rare person is able to purchase a new unit for himself. It is for this mistake that summer residents use cultivators made back in the USSR. On such walk-behind tractors, various difficulties with the engine often appear, however, there are many circumstances for this purpose. The main reason for the breakdowns is the service life, which has already come out for several years. Since recently, such tasks have been solved by Lifan engines on a walk-behind tractor, since this is a profitable method to solve the problem without the help of others and forever.

What engine is suitable for a walk-behind tractor?

The motor is one of the main elements of any mechanism and the efficiency of the entire device depends on it.

The motor usually consists of:

- distribution mechanism;

- cylinder block;

- carburetor;

- ignition;

- starter;

- cooling systems.

Initially, DM66 and DM68 motors were installed on walk-behind tractors. But they often fail due to improper operation, natural wear and tear and for other reasons, and therefore it is necessary to replace such a motor if it is not possible to restore it.

Lifan 168

One of the most common engines that are used for replacement is the Lifan 168. It has an engine capacity of 196 cubic centimeters and runs on gasoline. Power is 7 horsepower, air cooling, and therefore they can only work for a short time.

Installing the motor is simple and does not require re-equipment of the mounts on the frame.

Fluid replacement work is carried out as follows:

- with the engine turned off, unscrew the drain plug, which is located on the sump;

- drain the oil from the system;

- screw the plug;

- fill in new oil;

- warm up the engine;

- check the level and top up if necessary.

B&S I/C

The B&S I / C engine, which belongs to modern models and is popular in domestic conditions, can also be installed. Often they are used on Cascade units.

This is due to the following features of the motor:

- power 7 horsepower;

- reinforced transmission;

- enlarged combustion chamber;

- minimal noise during operation;

- high functionality even at low temperatures.

Vanguard OHV

The imported Vanguard OHV motor also belongs to powerful engines that can be installed on a walk-behind tractor of this manufacturer and cope with all the necessary tasks. This engine has a power of 7 horsepower.

Subaru EX17

You can also put the Subaru EX17 engine, which is popular among owners of Cascade walk-behind tractors. He has proven himself very well. It has a special design of the distribution mechanism inside and a large shaft diameter, which allows you to increase the engine power and efficiency.

As you can see, at present there are quite a few engines that can be installed on the Cascade walk-behind tractor. The choice of a suitable model depends not only on its functionality, but also on the financial capabilities of the owner.

It is also necessary to pay attention to the equipment, build quality and other points that are familiar to any motorist. If there are no skills, you should always turn to specialists for help.

The engine must meet all the requirements, which will allow it to operate efficiently and increase the service life.

Lifan engines, what is it?

The Chinese company Lifan has been around for quite a long time, because the company was founded in 1992 and continues to develop right up to the present day. With all this, Lifan is considered one of the main, to be more precise, one of the leading companies in the Chinese motor market.

The company itself develops not only engines. Her specialization is the creation of cars, bikes and other motor equipment. The company has really extensive experience in the development of engines for various vehicles.

In our country, this company has become famous for its Chinese engines for walk-behind tractors, since this is a fairly developed type of motor technology that is used everywhere. Previously, the goods had “made in China”, but for many Russians this caused rejection, since the Chinese rule worked - it means bad. At the moment, what remains to be done to our client, on the contrary, with the growth of the Chinese market, the quality of products has increased significantly, in this case, the cost of the product that remains to be done to our client also remains very applicable.

KEY DOP

What engine to put on a walk-behind tractor beam

The agricultural branch evenly includes small-scale mechanization, which can significantly simplify the process of earthworks.

An important role in this matter is played by walk-behind tractors from different manufacturers, which are distinguished by their compactness and relatively high power, depending on the type of motor used. Russian units are usually popular in the country, familiar to many since Russian times.

Specifically, we are talking about the Mole walk-behind tractor, which is the first model, serial production was launched in the USSR.

But, some are not happy with the factory engine that comes with the kit, wanting to change it to a more powerful one.

This does not mean at all about the poor performance of the “native” motor, alas, some want to put in a more powerful unit. Let's look at this issue from all sides, taking into account the technical features of the Mole walk-behind tractor, and of course find out which engine is an option to put at this address.

The mole cultivator, as well as the Cayman, Patriot, Texas, Foreman, Crosser, Viking, Forza motoblocks, is quite popular in the post-Soviet space, which is explained by the simplicity of its design and fairly good performance.

There is absolutely nothing superfluous in the configuration of this walk-behind tractor, but its device is made in such a way that it is able to manage basic agricultural work - dig up beds, cultivate the soil, etc.

Today, the design of the main working units allows it to withstand fairly long loads, providing measured work for a long time.

Expanded on the Mole motoblock, see the video:

the Mole walk-behind tractor itself consists of the following components:

Lifan 168F-2 (6.5hp) on Luch MB1

- The frame structure, consisting of 2 half-frames, is attached to the gearbox with bolts.

- Tubular type handles, also a special bracket for attaching additional attachments, located at the back of the structure.

- The main controls are placed on the handles - adjusting the engine speed, as well as the clutch.

- On the output shafts of the gearbox, it is possible to put on rototillers, additionally wheels that allow the use of a walk-behind tractor in conjunction with a plow, or for transporting various goods.

- On the frame structure there is a motor for the Mole walk-behind tractor, which is connected to the gearbox input shaft through a V-belt box.

- Today, in the design there are integrated wheels that allow you to freely move the unit. When starting work with a walk-behind tractor, these wheels must be removed from the structure, or raised and fixed in a suitable position.

As we see, the device is quite ordinary , not including unnecessary excesses in its capabilities. By and large, what remains to be done by our client, what is necessary for high-quality work on the ground - everything is in the design of this unit and the Sadko, Don, Huter, Profi, Plowman, Favorit motoblocks.

As for the industrial motor of the Mole walk-behind tractor, its device is a 2-stroke motor with one cylinder and air cooling.

Its volume is about 60 cm3, with a power of 2.6 hp. and 6000 rpm. It starts when using an ordinary cable, observing the principle of chainsaw winding.

It must be filled with a special mixture consisting of gasoline and engine oil. These properties are quite moderate, so they probably want to change it to more massive models.

The change of the industrial motor you like is done on your own , since the design of the Mole, as mentioned above, does not present a certain difficulty in your own awareness. In most cases, they use the substitution for 4-stroke versions of engines, that they have higher performance features than 2-stroke ones.

This, there are also some modifications, such as the Mole walk-behind tractor with a 4-stroke Honda engine, but its price will be much higher than that of the standard Mole. That is why we are considering the “worst” option, when we have a walk-behind tractor with the most standard factory engine, with a power of less than 3 hp.

The design of the frame of the motoblock Mole allows you to install on its surface and other enginesproduced at different factories. Here, the alteration of the frame will be small, consisting in a few simple manipulations.

Practice shows that it is necessary to take with a pulley shaft of 20 mm (there is still one type of 19 mm motor). It is also important to have an oil bath at the air filter, because such a device is used specifically for areas where there is excessive dust.

Today, of course, install the Patriot electric motor for the Mole walk-behind tractor, the price of which is within 6 thousand rubles. The only thing is that you need to take care of the electricity in your own area so that the device can work measuredly.

A good option comes out of installing a SadkoDE-220 motor on this walk-behind tractor, whose power is about 4.2.4 hp. The diameter of the shaft is 19 mm, it starts with a cord.

Characteristics of Lifan engines

“Lifanovsky” engines for a walk-behind tractor have different technical properties, according to which it is worth choosing a certain motor model for a certain model of a walk-behind tractor. The first and main feature is the correspondence of the installation dimensions. It will be great if you can find an engine that fits perfectly with the current mounts. Of course, choose a model without the help of others. You can also contact your local engine shop for expert help. It is important to keep in mind that if the fasteners do not match, then they will have to be redone without the help of others.

The next fundamental feature is the power of the motor, which is usually measured in horsepower. The most common universal engines for walk-behind tractors have a capacity of 6.5 horsepower. This power is usually enough for most walk-behind tractors. Engine models are very similar both in installation and maintenance, and in operation.

Types of motoblock engines

For installation on gardening equipment and heavy agricultural equipment, gasoline and diesel engines are used. The former are distinguished by high performance and the ability to work in difficult operating conditions, the latter are versatile and economical. The motoblock engine, running on diesel fuel, supports a large number of types of attachments. The best production effect is achieved when operating at low speeds.

Such units have a good motor resource and high resistance to negative weather and climatic factors. The most popular are two-cylinder models. They are relatively inexpensive and tolerate high temperatures well. When using such a motor in the summer heat, a simple air cooling system will suffice. Gasoline modifications require high operating costs for maintenance, maintenance and operation. Their advantages are durability and reliability.

A four-stroke engine of this type has high performance and the ability to work on heavy soils. A unit equipped with a vertical shaft saves time because it can operate stably at high speeds. Power units compatible with walk-behind tractors are divided according to the starting method:

- for electric;

- on manual;

- for combined.

Manual drive is found in the most budget and outdated models. More common units with electric start, providing an easy and quick start of equipment. They are economical, easy to operate and reliable. Using an electric motor for a walk-behind tractor is appropriate in the country or in your own garden. Combined modification is a convenient option. 4-stroke motors are based on such a functional scheme, designed to process large areas of arable land and agricultural land.

They greatly facilitate the task of the operator, because they allow you to choose the type of start that is convenient for you. Both petrol and diesel models are equipped with an automatic speed control. Another classification feature is the power indicator. Engines up to 4 liters are installed on light walk-behind tractors (less than 70 kg). With. On medium (71-100 kg) motors up to 7 liters are used. With. For joint work with heavy (over 100 kg) equipment, power units from 8 liters are used. With. The power limit is set at around 16 liters. With.

Light and medium motoblocks use two-stroke gasoline or diesel engines with an air-cooled system. They are well suited for household chores in a private home. Among farmers, the most widely used are equipped with a 4-stroke engine with a forced liquid cooling mechanism. Depending on the modification, the engine is equipped with a gear, chain or worm gearbox. The latter may have a V-belt or bevel gear.

How to install a Lifan engine on a walk-behind tractor?

The Chinese engine is usually installed in this case, when the native engine has become unusable or it is already stupid to repair it. The new engine then has great advantages over any Russian. After the purchase, the engine will amuse its owner for a long time with the way it is perfectly tuned. After all, usually, any new engine just starts up and works correctly for many years.

As mentioned above, the engine must be selected taking into account the size of the seats, because the complexity of installing the Lifan motor on a walk-behind tractor

depends only on the model of the frame itself, on which it is intended to perform the produced.

The installation itself will be carried out in a few ordinary steps, which even a person who is far from the topic and has never dealt with similar things will be able to cope with:

- Removing the old motor Usually done with ordinary open-end wrenches or heads. It is simply completely removed by previously disconnecting the gas cables, if any. Also, before removing, you should reset the belt that transmits torque to the gearbox.

- Installing a new motor. It is done using the same fasteners, in this case, if they match. In that case, no, that is, there is an option to recycle these fasteners on their own by drilling holes or even welding additional iron plates, if necessary.

Motoblock Master

Hello! I consider it my duty to warn you, if you do not have the proper education or experience, it is better to contact our workshop. It should be remembered that any mistake at the stage of disassembly, assembly of the unit will lead to a significant increase in the cost of repairs and a great loss of time. You can buy any spare parts for a walk-behind tractor, cultivator from our workshop or order cash on delivery by mail. You can get advice on your questions by phone.

What to do if the engine of the old MTZ 05, 06, 12 walk-behind tractor has become unusable? The engine can be repaired. Unfortunately, this is not cheap, and every year there are less and less spare parts for old UD 15, UD 25 engines. Therefore, more and more users are changing the engine, installing the Honda GX series or their analogues. They do not pull as well from the bottom as the old Soviet UD, but they are more powerful, more economical, more reliable. I won’t discuss the resource, by the way, it’s easier and cheaper to repair a Honda engine, spare parts for it are always available. And so: we change the old UD 15 to a copy of the Honda GX. Copies are offered by different manufacturers: Weima, Rato, Kipor, Magnum and others.

We disconnect the gas cable, the wire from the magneto, remove the fuel tank, in this case we didn’t have to do this, the walk-behind tractor arrived at the workshop in a semi-disassembled state.

Drain the oil from the gearbox. If it is the same as in this walk-behind tractor, then we also drain the oil from the final drives, left and right.

We unscrew three bolts on both sides that connect the engine to the gearbox, and disconnect the old engine from the gearbox.

We take the new engine out of the box and put it on the table.

As a rule, engines come from the factory without oil, this is written both on the box and in the instructions.

On the left side of the engine cover there is an information plate, which shows that you need to fill in oil along the lower edge of the thread.

We look at the brand and type of oil in the instructions, as a rule, for this engine 10W30 or 10W40, semi-synthetic for four-stroke gasoline engines.

For installation, you will need an adapter plate, and a new clutch hub (the old one will not work), a cup, if it is in good condition, you can leave the old one, you just have to disconnect it from the old hub and rivet it to the new one, or you can buy a ready-made clutch hub with a cup.

We also need a new gas cable, the old one will be short. In addition, you will need 10 more bolts with a diameter of 8 mm, a length of 25-35 mm.

Unfortunately, ready-made pads are hard to find. Therefore, we cut out the gaskets under the adapter plate, you can use special material for gaskets with a thickness of 1-2 mm. If special material is not available, use thick cardboard and sealant. It is important that the plate is pressed tightly against the engine and gearbox, otherwise oil from the gearbox will flow between the plate and the engine.

Use bolts of the correct length. It should be noted that the holes in the rear cover of the engine are not through, use an engraver when attaching the plate.

We cut out the second gasket.

From the old engine, we remove the native adapter, which stands between the engine and gearbox.

The distance from the edge of the adapter to the clutch cup must be 30 mm.

When we install the adapter and cup on the new engine, this distance must be checked.

Loosen three nuts on each side.

We remove the adapter, if the effort of the hands is not enough, we help with a hammer.

Remove the clutch cup from the old engine. To do this, you need to bend the lock washer, jam the cup and unscrew the nut, after which we knock the hub together with the cup with light blows.

We examine the cup, if there are not deep marks from the disks in the grooves, they must be removed with a file or a grinder.

This must be done very carefully, if the grooves are not even, the clutch will lead. After processing, we check the grooves with a new clutch disc.

We cut off or cut down, rivets from the hub, and then we knock out each rivet with a core.

Separate the cup from the hub.

Trying out a new hub. We buy or manufacture steel rivets, diameter 4.5 mm, or drill the hub and cup for finished rivets, rivet length 13-16 mm.

We connect the cup with the hub and rivet.

We put the key and hub on the crankshaft of the new engine. If the hub is tight, then first we push the hub, combine the grooves for the key on the hub and the crankshaft, hammer the key with the guide. We clamp the hub with a bolt with a diameter of 8 mm, a length of 50-60 mm, through an engraver and a large washer. The bolt can not be locked, the shaft rotates in the opposite direction.

We apply sealant to the adapter. If, after dismantling, the old gasket remains undamaged, you can use it after applying a sealant to it. We connect the adapter to the new adapter plate, while using six bolts with a diameter of 8 mm and a length of at least 35 mm.

We check that there is approximately 30 mm from the edge of the adapter to the edge of the cup, a slight deviation of plus or minus 1 mm is allowed.

Taking advantage of the fact that the engine is removed, we pay attention to the clutch and gearbox. It makes sense to replace the clutch discs, check the condition of the springs and bearings.

We dock the engine with the gearbox, for this we set the clutch basket with the protrusion up.

We also put the clutch cup on the engine with the groove up.

We install a new gasket, apply sealant and join the engine to the gearbox, while not needing to apply excessive force so as not to break the clutch discs. Usually, if everything is set correctly, docking does not cause any particular difficulties. We clamp six bolts, three on each side.

Old throttle cable, short.

Install a new cable. We remove the air filter and unscrew the nut with a socket wrench 10, it locks the gas lever, release the nut until the lever starts to move freely. The cable casing and the cable itself are fastened in the places provided for this.

We connect the wire to turn off the ignition, for this we use the wire that was previously connected to the magneto. It needs to be connected to the black wire on the new engine that goes under the fuel tank to the ignition coil. To do this, open the ignition wire, connect the engine stop wire to it, isolate and fix the wires with the clamp provided for this.

Unfortunately, the old stand will not fit, but it can be remade. For example, as in the figure below.

Or so.

Or like this.

All these homemade coasters are more likely to cause inconvenience in use, so it is better to buy a stand specially made for this model.

The walk-behind tractor is ready, the next step is launch.

Before starting, you need to open the fuel cock - a flag on the carburetor, which must be moved forward from you to the engine below.

Then, close the air damper, the lever, which is pulled towards itself from the top, from the engine, and then pull the starter handle. When the engine starts, the choke should be opened by moving the top lever forward away from you towards the engine.

The video shows the sequence of starting and stopping the engine.

It is important to remember that after you have stopped the engine, you should always close the fuel cock.

The best reward for work is a happy user.

Good luck.

Author: Martysevich Vasily.

City phone: +375(17) 512-37-12. Mobile phones : +375296741674 (A1, Viber and WhatsApp); +375298767878 (MTS).

Part 1. Replacing the engine of the Soviet MB-1 walk-behind tractor with the Chinese Forte F-200G

KEY DOP

Engine replacement

Russian

motoblock

MB-1 to the Chinese Forte F-200G. // Replacing the engine in the walk-behind tractor .

In fact, the walk-behind tractor " Cascade"

» is fascinating to summer residents as it is quite small-sized, comfortable for transportation. Designed primarily for work in summer cottages, small gardens and orchards. However, with all this, there is an excellent opportunity to expand the capabilities of this walk-behind tractor through the use of attachments.

Installation is quite easy, in most cases the mounts of the Lifan 6.5 motor coincide with the factory ones and you just need to change the engine, start it and start using it. However, there are times when the fasteners differ slightly. Under such circumstances, “getting out of the situation” is an option in different ways.

A simple method is to make an adapter plate into which you need to make holes for the motor mounts and weld it. If there is no such ability, simply screw it into regular places on the frame.

Installing a Chinese Engine on the Neva Motoblock

What engine to put on a motorcycle neva

Content

Motoblocks SALUTE (AGAT), FAVORITE, MKM "LANDER", NEVA. | | Author Topic: ALEXANDER

Good afternoon fellow forum users. I have another important question for you. In the garage, an old salute collects dust.

Vyacheslav (Alard) on my pier also with the right to install a Lifan engine

Basil (Broc) On a mole on the gearbox reducer pulley with a large diameter?

Vyacheslav (Alard) yes

Vasily (Broc) and here he stands on the gearbox. It's not a big pulley, it's an engine. Reducer

Vasily (Broc), this is the gearbox that he has, and the engine will go to Lifan

ALEXANDER (Magic) And what Lifan? Lots of models.

Vasily (Broc) Lifan 6.5 horses and enough to eat Piran, also 6.5 horses. They are almost the same, only the picture differs from the name. I'm in "Favorite" with the ZID 7 horses label and it's the main one in China that the shaft gets under the gear

Vasily (Broc) I threw you a picture of the gearbox on the engine

READ Makita 18 Screwdriver How Much Weighs

Vadim (Joe) I don’t have anything, how do you have a pozhizhayushi gearbox. And there is a direct shkolok!

Vasily (Broc) If there is a straight pulley, then there is usually a large pulley on the gearbox of the motor block

Vadim (to Joes) And what size pulleys do you have on the big one?

Vasily (Broc) I have a belt on the gearbox of the gearbox on a 12 cm pulley and on a motor gearbox with a diameter of 9 cm

Vadim (Joece) At that time, the gearbox was 14 cm. And the engine was 7.5 cm.

Vadim (Joes) This means I have a left hand pulley rotation. And you have the correct pulley rotation.

BASIL (Broc) Do you have the pulleys on which side of the bike when you look from the controls?

Vasily (Broc) and how does the engine move, where is the nose?

Vadim (Joece) And the rotation speed is the same!

Vadim (Joece) I'm standing on the left side.

Vasily (Broc). Here, the left of the counter-clockwise rotation of the engine turns forward and salutes. The nose of the engine is forward and the engine is back on its back here for this and puts the reverse gear

Vadim (to Joes) Yes, that's the way it is!

Tags: what engine to put on a motorcycle neva

Do-it-yourself MB2 motoblock! Motoblock Neva with Lifan (Lifan) engine, alternator, headlights.

Motorcycle engine. This is a quick change tractor.

Google.Com/ Undercarriage crawler tractor fast reengineering. Minitractor from Neva mb1 walk-behind tractor, adapter. Kholmsky.

I am changing the engine on a NEVA walk-behind tractor. YouTube

I am changing the engine on a NEVA walk-behind tractor. Engine replacement for motoblocks and cultivators. Garden mechanisms. Duration: 5:23.

READ How much oil is poured into the Al-Ko Lawn Mower Engine

Part 1. Replacing the engine of the Soviet MB-1 walk-behind tractor with the Chinese Forte F-200G

engine replacement

Soviet

motoblock

MB-1 on

the Chinese

Forte F-200G. // Replacing the engine in the tractor behind.

Installation of a Chinese engine for a MB-1 walk-behind tractor

I show how I installed the Chinese engine

POWER 6.5 HP

Motoblock

MB-1.

Motoblocks SALUTE (AGAT), FAVORITE, MKM "LANDER", NEVA. | | Subject: Sergey

Guys, tell me how to increase the speed of movement of the Chinese

walk-behind tractor MB.2M? He put Zhigov wheels on him with rubber from Volhynia, but he still crawls like a turtle.

Grigoriev (to Ikuko) I want to put on my Uralovs. On the net, it flies fast!

Slave pulley of Victor (Amaleki) reduces and the belt will be shorter

Grigoriev (to Ikuko) And the gearbox won't break?

Victor (Amaleiki) you change the diameter of the wheels. Thereby increasing the load on the gearbox. And here in the factory settings of its mode.

Grigoriev (Ikuko) You can move the engine forward so that the belts do not take others.

Victor (Amaleiki). Your drnn)))

Victor (Amaleiki) on my page for their instructions. Circuit

Victor (Amaleiki) https://ok.Ru/dk? Cmd = logExternalst.Cmd = logExternalst.Link = http%3A%2F%2F

Sergey (Tedd). There were recommendations for replacing the driving and driven pulleys. The problem is that the shafts have different diameters. Exit. Make a new pulley. But how will it affect the engine, won't it be overloaded?

Victor (Amaleki), reducing thrust less, will become

Victor (Amaleiki) loading the engine

Victor (Amaleiki) why the speed is increasing. With a large plowing of the engine. Structural calculation of the unit for a function with a certain engine power

READ How to install a rotary mower on a walk-behind tractor

Svetlana Mashkina (Soloviev) Now I will send a group

Sergey (Tedd). Of course, there is another option. Leave it the way it is. The device, although not fast (which is rarely required of it), but it weighs. An additional subframe was made, it became possible to put on belts for 1180.

Victor (Amaleki) not to hurt, perhaps a little less than 5-10% less.

Sergey (Tedd) Perhaps the more grippy the drive gear here is, the better. They fly on other MBs for nothing. Although, as they say, the owner of the owner. Dissonance.

Victor (Amaleki) changes design, no point elsewhere addressed

VICTOR (to Amaleiki) I use two engines. Tula and planet with starter and recycled magneto and also charges the battery. There are no generators inside. Stars and chain. Open definition and wheels

Vitaliy (Makhaniya) And how much is it in km / h crawling like a turtle?

Sergey (Tedd). There is a law of physics, you gain power, you lose speed, for any technique, if you want to travel fast, buy a Farari.

Replacement MB 2 Neva | Forum: house and cottage. forum house

February 10, 2011. I have been using this walk-behind tractor since the early 1990s, or rather my father bought it. engine for this motor. Replacement for MB 2 Neva. When I put in a couple extra cutters. I forgot about instillation. Installation

Chinese engines on the Neva | Forum: house and cottage.

Replacement of the engine for the motoblock Neva, Mol, Salyut.

Instructions for replacing the engine of the motor block. These are the features of various models.

Is the Lifanovsky engine suitable for the Krot motoblock?

A weaker engine with a capacity of 4 horsepower is installed on the Mole, due to the fact that the frame of such an instance simply does not allow you to install

more powerful engine.

The engine for the Mole walk-behind tractor is even cheaper, which for most people will only seem like a plus. For the size of this walk-behind tractor, this power is completely enough, it copes with the main task - to plow the land. Naturally, it is worth using it in completely small areas where high power and long-term work are not needed.

KEY DOP

Lifan engine reviews

Because walk-behind tractors are small-scale mechanization, they are popular in almost all countries in which people are engaged in agriculture. Indeed, without walk-behind tractors it is difficult to dig up the ground on your own small plot. A tractor is not necessarily comfortable and profitable, and digging by hand with a shovel is long and difficult, especially if the ground is fairly compacted.

Lifan engines for motoblocks have proven themselves really well, since they are not expensive. In addition, they do not require huge investments in the course of operation, they are undemanding in maintenance. With all this, the engines have good performance and are reliable.

Their development is mainly the merit of Japanese engineers. The Chinese industry occasionally develops something of its own> craftsmanship, new. In most cases, they simply adopt the experience of their own brothers, taking a successful copy as a standard. It should be noted that such engines are often used in portable generators, for which the reliability of the installed motor is a decisive indicator. Some even use walk-behind tractors for local transport, where there is an option to transport sand, firewood or something else.

Engine maintenance

In the process of use, there should not be any significant problems for which the design with a one hundred percent serviceable new engine is intended, while it is better to check it at the highest power during the warranty period. The motor is serviced by the owner without the help of others, although there should not be any problems with this with Lifan engines on walk-behind tractors.

If, nevertheless, tasks have appeared, you need to perform a number of simple procedures, after which the engine will again work “like new”:

- Change candles.

- Change oil.

- Check the integrity of all connections.

Not just no adjustments are needed, because the ignition in such engines is electric. After performing the above steps, of course, try to start the engine.

Motoblock repair

If it is not possible to start the Lifan engine installed on the walk-behind tractor, then it is worth performing an ordinary check. For this purpose, you need to perform a series of actions, during which it is easy to find the cause of the motor malfunction and simply remove it:

KEY DOP

- Check fuel supply. The motor can “grab”, but not start, because a bad suction of gasoline is being made from the tank. The reason may be a blockage of the drain hole in the plug, which serves to allow additional air to enter the tank, instead of the gasoline that escapes from there. The hose could be clogged with debris or something could get into the tank itself. It is necessary to check our client remains probable options.

- Check candle. If it has been smoked, as it is also called, it has completely broken through, then you need to change it, since it cannot be repaired.

After eliminating these defects, you can try to start the engine. If this does not help, then the cause must be found in the unit itself.

Major motor problems

Among the main problems of the Cascade walk-behind tractors are the following:

- The engine will not start;

- motor runs intermittently.

The causes of such malfunctions can be very different, from low-quality fuel to clogged candles. It could also be due to a dead battery. In this case, it is necessary to recharge the battery and clean the fuel line or spark plug, and if necessary, change it completely.

Another problem could be loss of power from the motor. The main reason in this case is the clogging of the carburetor or filter, which prevents the right amount of fuel from entering the combustion chamber. In this case , it is recommended to clean the system, as kickback is possible when starting the motor .

Read also How to care for mangoes at home

Experts recommend that to avoid such problems, periodically carry out maintenance of this equipment.

All of the above breakdowns occur quite rarely, and if necessary, you can fix them yourself, this does not require special knowledge. If there are difficulties with the maintenance or repair, then you can contact the specialists or look for the instruction manual on the network.

How to adjust valves?

After a certain period, you have to adjust the Lifan motor on the walk-behind tractor, as failures appear, in other words, it starts to work incorrectly. There are not so many real problems, according to which the unit can lead such a life incorrectly. One of the main ones is incorrect valve adjustment. It is quite easy to make it, the full range of work is carried out in stages:

- The valve cover is removed.

- The gap, as a rule, is from 0.02 to 0.12 mm according to all standards, so you need to take some kind of measuring probe, as it is also called a device for clear alignment.

- Next, the adjustment itself is made using a screwdriver and a measuring probe, which must be placed under the valve. The screwdriver again turns out the adjusting screw.

- After the option, you need to return the cover to its destination.

KEY DOP

Change of oil

Oil in the engine of the Lifan walk-behind tractor should be filled with high-quality, all-season, better from a good manufacturer. The change is pretty easy. First, the old oil must be drained. Then a new one is revealed and poured into the engine. It is better to carry out the function on a warm engine, but it should be turned off.

The amount of oil, as well as the quality of the desired oil, can always be found in the annotation for the motor. It also describes quite carefully what remains to be done by our client for repair and maintenance activities, so there should not be any problems with this.

Read also from the rubric

How much oil is in the gearbox of a motoblock Ural

The gearbox is one of the important components of the walk-behind tractor. Its task is to smoothly transmit torque from the motor to the wheels by means of a V-belt transmission. Among other functions of the gearbox, it is necessary to highlight the change in the speed and direction of movement of the agricultural unit. Like the other mechanism of a walk-behind tractor, the gearbox of an agricultural unit consists of certain parts. Given the type of gearbox, its design […]

What gear oil is better to fill in a walk-behind tractor

What is the best oil to use for a walk-behind tractor, how to change it correctly? A similar issue should be taken with particular seriousness, because the choice of a reliable tool has a direct impact on the durability of the unit and the quality of its work. In that case, no advice was found, then attention should be directed to the walk-behind tractor model. For example, in a diesel unit you need to fill […]