The device of the tractor MTZ-80 "Belarus"

The design of the tractor is based on a semi-frame structure, which has bearing crankcases for transmission units. The chassis is based on two pairs of wheels. The front pair is driven and has smaller dimensions compared to the dimensions of the rear leading pair. Its cab is closed and designed for use by one operator. It can be equipped with a set of different types of pneumatic, hydraulic or electric equipment.

Excavator based on MTZ-80 tractor

Maintenance

Like any equipment, the MTZ 80 tractor must undergo scheduled maintenance. It is of a precautionary nature. It is necessary to carry out in order to maintain the condition of the unit in good working order. In addition, maintenance will improve economy, operation and reliability.

This model has its own maintenance system. It consists of 3 temporary or numbered technical services. Their markings are No. 1, No. 2 and No. 3. These services are not included in the monthly. To perform an auxiliary check of the tractor's performance, there are seasonal maintenance and those that are carried out under special operating conditions.

The article contains technical data for the Challenger tracked tractor.

The video tells about the power of the MTZ 80 tractor:

Perform checks in the following order:

- No. 1 - after every 60 hours of operation.

- No. 2 - every 240 hours of operation.

- No. 3 - after every 960 hours of operation

What is the price of the Terrion tractor can be found by reading this article.

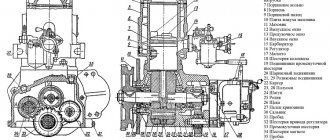

MTZ-80 engine

The motor of the model has a front location. And its power allows you to attribute the device to the traction class - 1.4. It has a 4-cylinder design and has 4 pins. It also comes with a semi-split combustion chamber. The engine is liquid-cooled, and on some models, a pre-heater is additionally installed, which ensures a stable start in cold weather. The rated power of the motor is 80 hp, which equates to 59.25 kW, while the first models were somewhat weaker. Starting the engine is provided, depending on the modification, by a starting motor or a battery-powered starter. The engine capacity is 4.75 liters.

Piston group of the engine D 240

For the repair of 4-cylinder MTZ tractor engines, special piston kits are produced, consisting of:

- cast iron sleeve;

- a set of piston rings (including 3 compression and oil scraper);

- pin for installing the piston on the connecting rod;

- piston

- a set of retaining rings for fixing a finger;

- sealing rubber gaskets that prevent leakage of coolant into the gap between the sleeve and the block.

The cost of the kit depends on the manufacturer of the spare parts. For example, the price of a set of MDK (manufactured by MD Konotop) is 2 thousand rubles, a similar set from 3.5 thousand rubles. There are separate sets of piston rings that include parts for a 4-cylinder engine assembly or for 1 cylinder. It is possible to buy rings in Moscow for the amount of 860-2400 rubles. (depending on the composition of the set).

Gearbox tractor MTZ-80

The transmission of the mechanism is used mechanical type. It has a 2-range 9-speed form and is equipped with a reduction gear. Its use provides the tractor with 18 forward and 4 reverse gears. In this case, it is possible to install a creeper on it. The rear axle lock is controlled on different models in two ways - hydraulically or mechanically. However, some versions are available with a hydraulic gearbox.

Tractor MTZ-80 Belarus - rear view

Device

Separately, it is worth considering the device of the tractor, as well as its main elements.

Transmission

All versions of such a tractor are equipped with a 9-speed gearbox, additionally equipped with a reduction gear. In total, this provides 18 forward gears, as well as 4 reverse gears. Additionally, optionally, it is possible to install a creeper in situations where it is required by the implementation of work. When knocks appear during the operation of the gearbox, which disappear in other gears, this indicates a misalignment of the teeth due to the destruction of the gears. Certain models produced after 1985 were equipped with a hydraulically controlled gearbox. This made it possible, without stopping work, to switch speed and made it possible to select a new gear in 4-range increments without removing the clutch.

Be sure to read: Tractor MTZ 1221 Belarus

Chassis

It is worth noting here that a balancing bridge was installed on the MTZ-80, which has a special semi-rigid suspension that allows the wheels to take the desired position. But the rear wheels are mounted with terminal connections directly to the drive axles. Due to this, they are able to change the track width in the specified range. The brakes on the tractor are disc brakes. In order to facilitate turning the steering wheel, a power steering is used, which works on a similar principle with automotive options.

Tractor engine Belarus

Cabin

On the MTZ-80 model, a cabin made of sheet steel is installed. At the same time, the inner lining is carried out for the purpose of warming, as well as soundproofing the driver's seat. Fastening to the frame is carried out by means of 4 rubber shock absorbers, which reduce shaking and vibration during operation. The driver has good visibility due to panoramic windows, as well as the presence of wipers for cleaning the front and rear windows. In order to ensure the flow of air, it is possible to open the roof or rear window, fixing it in this position. The steering column in the tractor can be adjusted in several planes at once.

There is a heating system for work in the cold season.

Specifications MTZ-80 Belarus

- Structural weight, kg 3900

- Weight in the state of shipment from the factory, kg 4000

- Operating weight, kg 4150

- Maximum allowable weight (full), kg 7000

- Base, mm 2450

- Overall dimensions: length, mm 3970

- Overall dimensions: width, mm 1970

- Overall dimensions: height, mm 2850

- Front wheel track (min), mm 1450

- Front wheel track (max), mm 1970

- Rear wheel track (min), mm 1500

- Rear wheel track (max), mm 2100

- The smallest turning radius, m 4.1

- Agrotechnical clearance of the tractor under the sleeves of the front and rear axle shafts, not less than, mm 645

- Front tire sizes 13.6-20

- Rear tire sizes 16.9R38

- Specific ground pressure, kPa 140

- Fuel tank capacity, l 130

- Movement speed: transport, km/h max 38.200001

- Movement speed: working, km/h max 15.1

- MMZ engine

- Model D-245.5

- Type 4-stroke, turbocharged diesel

- Number of cylinders 4

- Cylinder diameter, mm 110

- Piston stroke, mm 125

- Working volume, l 4.75

- Rated speed, rpm 1800

- Rated power, kW (hp) 65 (87)

- Maximum torque, N.m 396.799988

- Torque reserve factor, % 15

- Generator power rated, kW 1.15

- Rated voltage of electrical consumers of the onboard electrical network, V 12

- Rated voltage of the electric start system, V 24

- Clutch Dry, single disc

- Gearbox Mechanical, stepped

- Reducer Mechanical accelerator

- Front axle 3 piece

- Type of wheel reducer Bevel

- Differential type Self-locking

- FDA drive Two cardan shafts with intermediate support

- FDA control Mechanical with three operating modes

- rear axle

- Wheel reduction type Cylindrical final drive

- Differential type Simple, bevel

- Brakes Working Disk, dry

- Parking double disc, dry, independent

- Pneumatic actuator for trailer brake control Single-wire, interlocked with brakes

- Cabin Unified

- Rear PTO independent I (at rated engine frequency), rpm 540

- Rear PTO independent II (at nominal engine speed), rpm 1000

- Rear PTO synchronous I, rpm 3.57

- Steering Hydrostatic

- Swing mechanism type Hydraulic cylinder in the steering linkage

- Hydraulic system (HNS)

- Type of rear HPS Separate-aggregate

- Load capacity on the hinge axis of the lower links of the rear GNS, kgf 3200

- Number of hydraulic outputs of the rear HPS 3 pairs

- Hydraulic system

- Pump type Gear

- Pump displacement, cm3/rev 32

- Maximum pressure, MPa 20

- Pump capacity, l/min 46

- Hydraulic system capacity, l 25

- Chassis system Wheeled

- Wheel formula 4К4

Fuel consumption calculation

When calculating and calculating the cost of the work performed, an important component is the amount of fuel consumption by the tractor. The fuel consumption of MTZ 82 indicated in the characteristics by the manufacturer, taking into account the brand of the D-240 engine, is 238 g / kWh, which is completely inconvenient for an understandable economic calculation of the cost of work performed by equipment and accounting for fuel consumption. The most relevant unit of measurement is "liter per engine hour" of the tractor.

Factors affecting consumption

The characteristics specified by the manufacturer of the equipment are nominal average values. In practice, the deviation from the nominal value of the volume of fuel consumption is affected by a number of factors and conditions:

1 Technical condition of the engine, as well as the condition and adjustment of all systems

- Condition of the engine piston group

- Engine timing adjustment

- Adjustment and technical condition of fuel equipment

- Condition and operation of the air supply.

- Tractor cooling work.

2 External factors

- Driver Qualification

- Type of work performed

- Weather

- Humidity and physical condition of soils.

3 Fuel quality

The composition of the fuel must comply with quality standards in accordance with approved certificates, without foreign physical contaminants and chemical impurities.

Calculation formula

P = M * T

where, P - fuel consumption kg / h, M - rated engine power kW, T - estimated fuel consumption per 1 kW per hour.

And so: Consumption of MTZ 80 with an engine of model D 240., where, according to those. characteristics, fuel consumption is 0.238 kg \ kW * h and the rated engine power is 59.25 kW. at 2200 rpm of the crankshaft. (initial engine indicators are taken from the technical documentation of the manufacturer's plant)

Р=59.25kW*0.238 kg\kWh=14.1 kg\h

To convert from kilograms to liters, we use the coefficient:

- For winter diesel fuel 1kg-1.19 liters

- For summer diz. fuel 1kg -1.16 liters

“Rated consumption at engine speed of 2200 rpm and output of maximum power of 59.25 kW is 16.35 liters per hour of summer and 16.78 winter grades of diesel fuel.”

Tractor load factor

The actual used engine power depends on the work performed by the tractor and in practice, the average value does not exceed 60%. Accordingly, when calculating consumption, it is not the maximum engine power that is taken into account, but the actual power used during the work performed. For an objective, actual calculation of consumption, the tractor load factor is used:

- Full load -1

- Partial load -0.8

- Average load - 0.6

- Light load - 0.4

Tractor "Belarus-80": overview and description of the tractor

Add to favorites

MTZ-80, or "Belarus-80" is a universal wheeled tractor, which was created for the cultivation of chernozem soils for various tilled crops, as well as for the purpose of active use as a transport unit, service in public utilities, etc. Despite its relevance and today, the model is a conveyor long-liver. The first serial samples were produced at the Minsk Tractor Plant in 1974. But with a large number of upgrades, the tractor is produced to this day. It can be safely considered one of the most massive wheeled vehicles in the countries of the former USSR - from 1974 to the present day, about two million units of "Belarus" have been produced.

Calculation of the fuel consumption rate MTZ 80 per 100 kilometers

The consumption is determined based on the speed technical characteristics of the tractor, the specific consumption l/m.h and the load factor.

1 determine the time during which the tractor will travel 100 km.

Where B is the run time of 100 km, C is the speed per hour (for example, the speed the IX transmission of MTZ-80, MTZ-82 with the D-240 Engine is indicated).

B=100/C

B = 100 / 34.31 = 2.915 hours.

2 determine the amount of fuel per 100 km of run.

P per 100 km \u003d B * P * 0.6 where, P is the specific consumption of the engine D-240 l / m.h, B is the run time of 100 km in IX gear, 0.6 is the load factor.

R per 100 km = 2.915 * 16.35 * 0.6 = 28.59 l / 100 km

Table of fuel consumption per 100 km of run, taking into account the choice of gear and load factor.

km/h

The need for this calculation arises only when using a tractor in transport work on paved roads, which in itself is a rare exception in the use of this kind of equipment. The cost of transporting a ton per kilometer by such transport will be disproportionately high compared to road freight transport.

If the tractor is used in transport work within the city, the unambiguous objective unit of accounting for consumption will still be a liter per hour. It is enough to take into account: the operating time, the power of the diesel model, the specific consumption for this engine and determine the load factor, which in practice will not be higher than 0.6.

Advantages and disadvantages

- The main advantages of the Belarus-80/82 tractor include the following:

- availability and wide choice of tractors in the primary and secondary markets;

- a wide selection of new and used parts for every taste and budget;

- a wide range of additional equipment, which is produced for the most popular tractor in the CIS.

- Among the shortcomings it is worth noting:

- low power and load capacity, which to some extent limits the scope of the tractor;

- low level of comfort in the cab for the tractor driver;

- low quality of most consumables and spare parts that are produced without proper quality control.

Source

Model range and modifications

Back in Soviet times, the Minsk Tractor Works developed several modifications, in addition to the basic one. Among them, it is worth noting the 80XM modification for cotton fields, which had one steered wheel in front, the 82T modification for vegetable growing, which was distinguished by increased ground clearance due to the introduction of wheel gearboxes, the 82P was intended for rice growing, the T80L version was used as a skidder in logging.

Today, the plant produces a dozen and a half modifications, which differ among themselves in engine power (81-95 hp), installed transmissions, the number of drive axles and maximum load capacity. Most of the exotic and modifications described above have been discontinued.