The MTZ 1523 tractor model left the production lines of the Minsk Plant in 2009. The development of the model was the result of the implementation of a set of improvements and upgrades to the MTZ 1221 tractor. The purpose of creating the machine was to maintain a competitive position in the global tractor market, as well as to produce a universal high-performance machine with a wide use, including all types of tillage and agricultural work, plus the use of a tractor in public utilities, construction and other industries. The use of hydroelectric engagement drives in the designs of transmission units and equipment of the machine made it possible to improve the ergonomics of the tractor control and its performance. The skeleton of the machine has a traditional semi-frame design of a wheeled tractor. MTZ 1523, 1523V became the two basic versions of the series. The 1523B machine is designed for continuous use in reverse mode. It features an additional reverse control post with a swivel operator's seat and duplicate controls: clutch, fuel supply, brake, rear steering column. The subsequent evolution of the model in the modification 1523.3, 1523B.3, 1523.4, 1523.5 is to increase the environmental standard of the machines.

The tractor belongs to the third traction class with power from 148 to 155 hp. depending on the modification of the model. With its performance and use in wide-cut tillage units, the machine successfully competes with a tractor of a similar class of the KhTZ T-150, T-150K brands. At the same time, the MTZ 1523 fuel consumption is 30% less, and the machine also differs significantly in the level of comfort and ergonomics of the operator's workplace.

Engine

The tractor is equipped with a turbocharged, six-cylinder D-260 diesel power unit with a cylinder operating order of 1-5-3-6-2-4. The abbreviation "1S2" in the modification of the unit indicates the equipment with intermediate cooling of the air blown by the turbine. The motor is operated with a rated torque safety factor of 15-25%. The engines are equipped with six-plunger in-line fuel pumps of the Motorpal brand manufactured in the Czech Republic or Yazda - Russia. And also the unit is completed with two types of turbocompressors of the brand "Turbo" - the Czech Republic and OJSC "BZA" - Belarus. Automatic control of the thermal regime in the cooling system is carried out by two thermostats.

D-260.1S2 engine of MTZ 1523.3 tractor

| Modification | Engine brand | HP power | Fuel consumption g/kWh | environmental standard |

| 1523 | D-260.1 | 148 | 227 | stage I |

| 1523B | D-260.1 | 148 | 227 | stage I |

| 1523.3 | D-260.1S2 | 150 | 250 | stage II |

| 1523.3B | D-260.1S2 | 150 | 250 | stage II |

| 1523.4 | D-260.1S3A | 150 | 250 | stage III A |

| 1523.5 | D-260.1S3B | 153 | 222 | stage III B |

Specifications

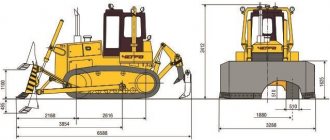

The technical characteristics of the tractor meet the requirements for medium-class traction equipment. The machine is large-sized, with a spacious cabin. Geometric parameters:

- length - 4.71 m;

- width - 2.25 m;

- height - 3 m.

The weight in the complete set is 9 tons. The tractor is characterized by economical fuel consumption - 220 g / kWh with average tractive effort. The machine is equipped with a capacious 250-liter fuel tank. To ensure movement in the reverse mode, the tractor controls are duplicated. Thanks to a powerful engine, the machine without attachments and ballast can reach speeds of up to 32 km/h in the forward direction and 15.5 km/h in reverse.

- track on the front wheels - 154-211 cm;

- track on the rear wheels - 152-243 cm;

- ground clearance - 62 cm;

- maximum turning radius - 550 cm;

- specific ground pressure - 150 kPa.

Transmission and chassis

The power transmission of torque from the engine to the transmission of the tractor is provided by a dry double-disc permanently closed clutch with a hydromechanical drive. Gearbox mechanical, synchronized constant engagement with 16 forward gears and 8 reverse speeds provides forward speed in the range of 1.74-32.58 km.h and reverse movement at a speed of 2.73-15.61 km.h. The unit has four forward shift ranges with four speeds in each range and two reverse ranges with the same number of speeds. The power of the tractor and the layout of the tractor transmission allows towing a load of up to 15 tons on a slope of up to 12̊.

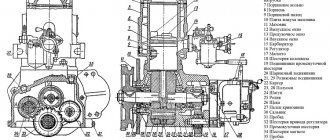

MTZ 1523 device

A box of a similar type with 24 forward gears and 12 reverse speeds is installed in a custom configuration with forward speed in the range of 1.7-36.3 km/h and reverse speed of 2.5-17.1 km/h. The unit has four ranges of six speeds each and two reverse speed ranges of six speeds each.

The rear axle has a traditional design:

- main gear bevel with helical teeth

- differential lock

- final drives with pairs of cylindrical gears

- planetary final drives

Front drive axle portal type with removable sleeves:

- main gear bevel with helical teeth

- final drives with planetary spur gears

The FDA drive is carried out from the gearbox through a friction electro-hydraulic clutch and cardan transmission. Control with automatic switching on is carried out by an electro-hydraulic distributor. The chassis of the tractor with a rigid frame suspension is equipped with pneumatic tires 420/70R24 for the front wheels and 520/70R38 for the rear wheels. It is possible to pair the wheels on the rear drive axle of the machine using a spacer. The minimum turning radius of the tractor with braking is 5 meters. The height of the clearance allows you to overcome the ford with a depth of up to 0.85 meters.

Layout

The design of the tractor does not differ from previous models.

- The diesel is located longitudinally in front of the machine.

- Behind him is the gearbox and rear axle.

- The rear hitch, cab, half-frame are attached to the transmission housings. The front axle rests on the latter.

- The engine is covered with a decorative hood with streamlined shapes.

Dimensions

MTZ-1523 at first sight fascinates with its appearance and size. The device looks especially impressive when twin wheels are installed on it.

But, despite the impressive dimensions, the tractor turned out to be maneuverable. The designers achieved this by reducing the wheelbase and the minimum turning radius.

To compensate for the loss of controllability when attaching heavy implements, weighting agents weighing slightly more than a ton are provided.

Cabin

The operator's workplace in this series has been tried to be comfortable for the operator.

- The cab received a rigid steel frame that protects the operator when the machine rolls over.

- Cylindrical tinted glass gives the cabin an extra beauty.

- Maintaining a comfortable temperature inside the cabin, the designers assigned to the ventilation system. It works in 2 modes: blowing and heating.

- By separate order, it is possible to install an air conditioner that will cool the blown air.

Brakes, steering and PTO

The brakes of the car are eight disc, working in an oil bath. The drive is hydrostatic interlocked with the pneumatic drive of the trailer. Parking brake with a mechanical drive of wet friction connected to the mechanism of the main brakes of the tractor.

The rear two-speed PTO MTZ 1523 operates in an independent mode with a rotation of 540 and 1000 rpm. and in synchronous mode 3.8 and 6.2 rpm of the path. On request, the tractor can be equipped with a front PTO with independent drive.

The hydrostatic steering is equipped with: a left-hand rotation gear pump with a working volume of 14-16 cm3 per revolution providing a pressure in the system of 16 MPa, a gerotor-type dosing pump with a capacity of 160 cm3/rev. The turning mechanism is equipped with two hydraulic cylinders 50x200mm.

Prices and analogues

When buying a new basic tractor, you will have to pay - 3.1 million rubles. Price may increase depending on dealer and optional equipment installed.

Cars on the secondary market are sold for 1.9-2.1 million rubles. The amount depends on the year of manufacture, the general technical condition of the tractor.

Among devices similar in parameters, one can single out Kharkiv KhTZ 242K, KhTZ 242K.21, KhTZ 242K.20, Slobozhanets XTA-220-10, Altai T-402-01.

Hydraulics

The MTZ 1523 hydraulic system is equipped with an integral block of the BOSCH brand, which provides power, positional and mixed regulation of the position of agricultural machines. Gear pump NSh-32-3 of right rotation with a maximum capacity of 55 liters per minute, providing a pressure of 20 MPa. The BOSCH integral block includes a four-position three-spool distributor and an electro-hydraulic spool regulator HER-23LS, powered by an on-board electrical network with a voltage of 12 volts. The hinged system is equipped with a pair of hydraulic cylinders Ts90x250. Prior to the installation of the integral unit, the tractor was equipped with a BOSCH distributor and a BOSCH EHR4 regulator. The tractor is equipped with a towing device TSU-3V of an elevator type, adjustable in height.

Electrical system and equipment

The onboard electrical system has a voltage of 12 volts, starting 24 volts. The tractor is equipped with two batteries connected in parallel with a voltage of 12 volts and a capacity of 120 Ah each. Discharge current when starting the engine 880A. The generator with built-in rectifier and voltage regulator supplies 14 volts. A tractor with a D-260.1 engine is equipped with a unit with a power of 1150 watts and a generator with a power of 2000 watts with a D-260.1S2 engine.

The lighting and light signaling system of the machine includes:

- a pair of front road headlights with low and high beams

- four working front and four rear lights

- two front marker lights with turn signal

- taillights with turn signal and stop signal

- license plate light, road train sign light

- cockpit ceiling, hazard warning lights

The audible alarm system is triggered when the oil pressure in the engine drops, the engine temperature rises, and the pressure drops in the tractor pneumatic system. To connect the towed machines to the tractor's electrical system, it is carried out through a nine-pin combined socket.

Control and signal devices of the operator's workplace:

- voltage indicator with additional battery charging signaling

- fuel gauge with reserve level alarm

- coolant temperature indicator with alarm for emergency temperature increase

- oil pressure indicator in the engine with emergency pressure alarm

- air pressure indicator in the pneumatic system with emergency pressure alarm

- oil pressure indicator in the hydraulic system of the transmission of the machine

- high beam alarm

- tractor and trailer direction indicator

- parking brake lamp

- air filter clogging light

- oil pressure lamp uphill

- liquid level control lamps in master cylinders

- paw for switching on the differential lock and FDA

The combined indicator is equipped with indicators:

- pointer speed indicator

- pointer indicator of engine speed

- light PTO speed indicator with colored segments

Aggregation

The tractor has a wide range of applications in soil-cultivating units and other agricultural machines, and is also used to attach driven special equipment to the tractor on the rear and front hitch.

| Aggregated skh. car | Specific resistance of medium soils kN/m , at a speed of 5 km/h | Machine working width |

| Share plow | 12-14 | 2-2,5 |

| Disc harrow | 1,6-2,1 | Up to 12 |

| Ploughshare cultivator | 6-10 | 3-4 |

| Cultivator | 1,6-3 | To 10 |

| seeder | 1,2-1,8 | Up to 12 |

| reaper | 1,2-1,5 | Up to 15 |

| Trailed harvesters: | ||

| forage harvesters | 2,6-3,3 | Until 3 |

| beet harvesters | 6-12 | Until 3 |

| potato harvesters | 10-12 | Up to 2.7 |

| A change in speed of 1 km/h changes the resistivity up to 1% | ||

MTZ 1523 with trailed plow

Major faults and repairs

One of the priority features when choosing an MTZ Belarus tractor is the ability to quickly perform the necessary repairs in the field. During the operating period specified by the manufacturer, the unit is characterized by stable operation, regardless of the intensity of use. The maintainability of components and mechanisms is quite high.

According to numerous reviews of machine operators, the ratio of price and quality is optimal. And malfunctions and breakdowns are caused, most often, by improper operation, negligence in work, illiterate maintenance, and incorrect use of attachments.

Advantages and disadvantages

The release of the machine, its subsequent operation and maintenance are focused on the economic trend of the general globalization of the world market. High-tech machine components require repairs in the manufacturer's service network, which has an appropriate specialized material base and staff qualifications. The MTZ 1523 tractor is a complex, high-tech machine that requires appropriate professional training and operator qualifications.

The engine of the machine is equipped with a powerful radiator that eliminates overheating at maximum speeds and loads. Taking into account the additional fuel tank, the tractor has a sufficient regular filling volume of fuel. The place of work has a convenient placement of controls and good noise and dust isolation providing comfort. The cab with spherical glazing provides maximum visibility to the driver of the machine. The rear linkage of the tractor is equipped with a sufficient set of universal coupling and traction devices for fast and reliable connection with the machines used.

The release of the MTZ 1523 machine is the result of the strategy of the enterprise's participation in the formation of the world market for agricultural machinery. The confirmation of the course is the certification of all manufactured equipment in accordance with the standards of the European Union. In 2000, the Minsk Tractor Plant confirmed the level of production quality by obtaining a document of conformity according to ISO-9001. World standards have been confirmed by a certification audit carried out by the German company TUV-Thuringia.

Device

The tractor has an improved undercarriage with front wheel drive, which have a smaller diameter than the rear ones. The driven axle is equipped with large-diameter wheels and acts as a rear half-frame. The machine is controlled by a friction clutch. To reduce the pressure on the ground surface, it is possible to install twin wheels, which are equipped with disc brakes.

This model of the machine has a reproductive hydraulic system from the German company Bosch. It provides the possibility of successful interaction of the tractor with various agricultural equipment and other attachments in the most difficult working conditions.