Tractors have long been replaced by horses, and harrows have become more advanced and efficient, and can be installed not only on heavy and medium agricultural machinery, but also on mini-tractors and walk-behind tractors. This type of equipment allows not only to break up large clods and cover the soil to retain moisture, but also to collect the remains of dry vegetation, as well as remove its roots.

There are the following types of harrows:

- dental or classic;

- rotary or rotary;

- disk.

According to this classification, harrow attachments are classified as heavy, medium and light. A harrowing device for the Neva walk-behind tractor can be bought at a specialized store or you can do it yourself.

traditional harrow

The classic, or as it is also called, horse harrow, is used to create a flat and loose surface. Also, this type of attachment allows you to qualitatively cover moisture in the soil and thereby prevent it from drying out. The harrow crushes large clods of earth to the required fraction, destroys weeds and removes vegetation residues from the soil. The equipment is quite light and therefore used for surface tillage, crushing of earth clods and shallow loosening before sowing.

Tooth harrow for factory-made walk-behind tractors is made of special structural steel that can withstand significant loads. Also, this equipment levels the soil well after milling.

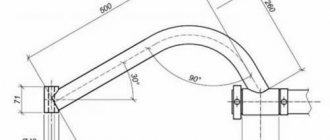

This type of harrowing equipment is a straight or zigzag frame that can be made by hand from a steel strip, a square pipe or an angle, a rack for a hitch with a walk-behind tractor and teeth. You can fix the teeth on the frame by welding, or by threading them, fix them with nuts. The working bodies on the frame are located at a uniform distance from each other, and their length can be 25-45 mm. Regarding the width of the equipment, then, for example, 500-600 mm is enough for the Neva walk-behind tractor. The video below shows the tooth harrow in action.

You can also make a motor-block tooth harrow with your own hands and according to the drawing below. It will take half a day to make such attachments, but it's worth it.

Scheme of a tooth harrow for a walk-behind tractor

In order to make such equipment for a walk-behind tractor, we need the following:

- weld iron strips to a metal square-section pipe, on which, in fact, with the help of nuts, teeth with threads cut on one side will be attached;

- the drawbar of our attachments ends with a welded sleeve, through which, with the help of a metal pin, a connection will be made to the walk-behind tractor used;

- we make a stand with an adjusting screw to adjust the lifting height of the harrowing device in order to ensure uniform penetration of the working bodies into the soil.

At least purchased factory equipment, at least a home-made harrow, for the Neva walk-behind tractor, there is a peculiarity of accumulation of wet soil with vegetation residues on the working bodies, as a result of which land cultivation may become inefficient. In order to easily and easily clean the teeth with a scraper or any metal object, we use the lifting lever of the unit.

Do-it-yourself harrow for a walk-behind tractor

What is a harrow made of?

Metal strips are welded to the bottom of the square pipe, at the ends of which teeth are bolted in two rows (photo 3). These strips are placed at an angle of 30⁰ to each other, the stakes of the earth that slip between the teeth of the first row (front) are broken against the teeth of the second row.

The drawbar ends in the boiled bushing, through which the harrow is fixed with the help of a “finger” to the walk-behind tractor. The lifting height is adjusted by the harrowing depth stand (photo 4).

An adjustment screw for the angle of attack is welded to the drawbar next to it - it is he who allows you to adjust the design so that the rear and front teeth fall into the same depth.

Features of using a harrow on a walk-behind tractor

Sometimes, during operation, the harrow becomes clogged. It is very easy to clean it, without even bending over. When raising the handle of the walk-behind tractor, we tear off the harrow from the soil surface, take it to the side and discard with our feet all the debris that has accumulated on the teeth. Then we return the tool to its original place, lower it and continue moving.

Rotary equipment

A rotary or rotary harrow is used, as a rule, for cultivating the land after harvesting grain crops. Also, this type of equipment for a walk-behind tractor well levels the surface of the earth and removes weeds. The rotary harrow consists of six working edges, discs and a bushing. The equipment has undergone changes, and it was revealed that for greater efficiency, the working blades should be set at an angle, which makes it easy to cut and level the soil during processing. A do-it-yourself harrowing device is installed on the unit instead of wheels or lugs. The video shows a homemade rotary type harrow for a walk-behind tractor in operation on the site.

Looking at the presented photo, it may seem that it is not difficult to make such a harrow with your own hands, however, in order for it to work normally, it is necessary to correctly calculate the entire structure, namely the angle at which the working edges are set.

Description mounted disc harrow for MTZ 82 for tillage

A disc harrow is an agricultural unit that can become a worthy replacement for a cultivator, plow, cultivator. Thanks to this nozzle, it becomes possible to cultivate the land, in which the moisture level is not more than 25%. What it looks like and how to choose the right mounted mineral fertilizer spreader is indicated in this article.

This type of hinged structure consists of a specific number of disks. Relative to the vertical main axis of the structure, they are concentrated at an angle. This is what allows you to adjust the depth in the ground and determine the angle of processing.

On the video - disc harrow for MTZ 82:

According to the design of the working part, this device can be divided into two types: hinged and mesh. You can learn about how the Polesie combine harvester is used from this article.

When the land is being cultivated, where there are many roots from previous plants, it is extremely profitable to buy a disc harrow designed for stone soil.

The mesh design is an old model, but it has already been tested by time. The basis of the product is made of a metal mesh, on which the teeth are attached in various ways. Mounting of the teeth can be different depending on the intended purpose. The teeth can be presented in a curved form, straight and as a spring element.

For a more correct distribution of fertilizer, loosening the earth with vegetation residues, it is necessary to use a harrow with discs that can increase the resistance of the soil surface to various kinds of erosion processes. It is also necessary to increase its absorption capacity.

Also, the presented devices, working in tandem with the MTZ 82 tractor, can be divided according to their intended use. The price of a trailed combine harvester PN 100 prostor and other data are indicated in the article.

field

They are used for cultivating the land after tilled activities. Certain models can be equipped with boxes that serve as ballast weights. Thanks to such measures, it is possible to process the soil to a sufficiently large depth.

Trailed garden for tractor

This type of construction is characterized by its light weight. Serve for processing soil between rows in the garden and in the vineyard. When using such a harrow, it is possible to loosen the ground to a depth of 10 cm. A video about the Challenger tractor and other features of the unit are indicated in the article.

marsh

Processing can be carried out to a depth of 20 cm.

This type of device is actively used for disking on waterlogged soil and for processing virgin lands.

The disc harrow for installation on the MTZ 82 tractor is a device to which a battery with working parts is fastened. Soil cultivation is carried out with the help of steel discs, whose dimensions are 450-510 mm. It is steel discs that are the main working bodies of the harrow. The price of Terrion 3180 and other technical data can be emphasized for yourself from the article.

If several such elements are placed on one axis, then it will be possible to get a battery. Its fastening is carried out using bushings. Due to this, while the tractor is moving, the battery will rotate.

On the video - trailed disc harrows for MTZ 82:

In most cases, the installation of a battery with disks is carried out in several rows. The plane of penetration of the device into the ground is called the angle of attack. Its value can be 1-20 degrees. It is necessary in order to determine the hardness of cultivated land. The harder it is, the larger this angle should be. How to make a manual potato hiller with your own hands, you can find out here.

The work of the disc harrow is carried out according to the following principle. The battery, which is mounted closer to the tractor, breaks up the soil. But the second battery closes it. To perform cultivation with maximum efficiency, it is necessary to achieve displacement of the disks of the front and rear battery relative to each other's axis. The tractor begins to move around the territory at a speed of 15 km / h. The disks, concentrated on the first battery, begin to open the earth layer to a certain depth. The soil rises, as the disk has a spherical structure, is moved aside and placed from a low height. A video about an electric cultivator for giving and technical parameters of the equipment can be seen in the article.

The second way in a similar way returns the earth to its place. The result of such processing is turning over and grinding the soil. With an increase in the angle of attack, the disks will go into the ground to a greater depth.

Homemade disc harrow

The drawing shows the dimensions for a mini-tractor, therefore, when making attachments for a walk-behind tractor, we adjust all the values to the dimensions of the power unit. One section was borrowed from a large tractor discator, consisting of 8 lenticular discs with a diameter of 450 mm with an inter-disc distance of 150 mm. The video clearly shows the work of equipment made by oneself and installed on a walk-behind tractor with an adapter.

Disc harrow drawing

The disk section is movably fixed on a metal frame 1400x650 mm and welded from an angle 50x50 mm. The capture of such home-made equipment is 1200 mm with a depth of up to 100 mm, and the angle of attack is adjusted to 17˚. As already mentioned, in order to use the harrowing device together with the Neva walk-behind tractor, the frame length can be halved and, accordingly, only 4 disks can be used.

How to do it yourself for a small sown area?

Before starting independent work on the harrow device, it is worth studying its design and drawings . Then it will be easier to determine the dimensions and possibly simplify the unit in some parts.

Components

The design of the unit itself is simple:

- a frame consisting of square metal plates;

- coupling device of a harrow with a walk-behind tractor;

- teeth located at the bottom of the frame.

When installing the teeth on the frame, do not weld them, but fasten them with bolts . So having broken one tooth, it will not be necessary to redo the entire frame, but simply replace the damaged tooth.

To make it easier to assess the future front of work, look at the drawings of the harrow device.

Device drawings

Below are the technological drawings of a harrow for a walk-behind tractor. The most important parts of the unit are defined here.

And this is what a homemade harrow looks like:

Here the unit is arranged from two parts of small harrows, and is rigidly fastened together. The longitudinal course of the device is made using a hinge with a GAZ 53 car. But in addition to the hinge and the standard towed device, the unit is fixed with two rods to improve the performance of the harrow.

Scheme of a homemade harrow for a walk-behind tractor

The use of horses to plow the land is a thing of the past. Now more constructive and advanced equipment has come to help farmers. One of them is a harrow on a walk-behind tractor, which allows you to increase the speed of planting and harvesting crops, and, consequently, increase the yield.

Such devices break up large pieces of land, retain moisture in the soil, remove the remaining dry grass and its root system. You can also make such attachments for a walk-behind tractor with your own hands, which will not only help save significant financial resources, but also take pride in the work done.

Types of harrows

A harrow for a walk-behind tractor is a device that is attached to the unit for agricultural work. Its purpose:

- Loosen, mix and level the cultivated land;

- Remove weeds;

- Thin out seeds that are too closely planted;

- Destroy the top crust on dry soil;

- Introduce seeds and fertilizers into the soil;

- Improve the saturation of the earth with oxygen.

Direct contact with the soil surface takes place with the help of tools attached to the frame in the form of teeth, discs, hoes.

Harrows are divided into different types, depending on their device. They can be toothed, rotary, or disc. They are also divided into heavy, medium or light, depending on the design.

Let's consider all types of devices in more detail, and also find out how you can make a harrow for a walk-behind tractor with your own hands.

Do-it-yourself tooth harrow

This device is the easiest to make yourself. If you have metal materials, a grinder and a welding machine, then the process will not cause many difficulties.

To produce a harrow for a walk-behind tractor with your own hands, you need to understand the drawings and determine the required dimensions.

The design looks like a lattice, with teeth welded to it. If possible, they are recommended to be bolted to ensure replacement in case of breakage. A trailer to the walk-behind tractor must be provided in front. To facilitate work, a chain is welded between the two units.

The grille is made from durable materials. They mainly use pipes for plumbing and corners with a thickness of more than 4 millimeters so that the teeth do not come off the thin-walled base. A more robust design involves welding the bars at a 45-degree angle to the movement, which reduces stress.

The size of the grid cells should correspond to the size of the teeth. The frame size is designed in such a way as not to interfere with the control of the walk-behind tractor.