The principle of operation of the snowplow cultivator

A motor cultivator is a multifunctional, reliable and versatile technique that can cope with a variety of tasks. Such a unit is relatively easy to adapt for snow removal. But for this you need to understand the principle of operation of the snow blower, and what is required for this. The advantages of this technique are the following factors:

- Affordable cost;

- Versatility;

- Ease of maintenance;

- Practicality;

- Long service life;

- Resistance to increased loads;

- Protection against moisture and mechanical damage.

Depending on the power of the cultivator, the snow blower is capable of throwing snow at a distance of up to 8 meters or more. The main working unit of such equipment is the auger shaft from the motor cultivator, which first collects snow, and then pushes it into a special chute, from where it is subsequently thrown out to a sufficiently large distance, and in the right direction. Snow is thrown off by shocks, the formation of which requires additional adapters and belts. To put the device into operation, you need to connect the shaft to the snow blower. Usually carried out through a belt drive.

The principle of the machine

It is worth noting that a snow blower from a cultivator will turn out to be excellent, if only because it is able to throw snow very far to the side. It all depends on the power of a particular motor, but the distance can be up to 12 meters.

Such a machine has a standard metal body, in front there is a bucket with an auger raking in snow. With the help of an auger, snow is fed to the impeller, which throws it out through the pipe. Snow is driven out with powerful pushes, which are provided by reliable belts and adapters inside this entire system. To create such a machine with your own hands and actually combine two in one: a motor cultivator and a snow blower, you will need to use a belt drive.

Mounted snow blowers for motoblocks and motor cultivators

Snow blowers are distinguished by several features. They can be passive, which are attached to the front of the equipment. The effectiveness of their work depends mainly on the skill of the operator. The second type is active (brush or screw). Differ in higher quality of cleaning and ease of management. The operator controls the speed of movement and the direction of snow throwing. In addition, the snow blower and cultivator differ in the principle of operation and their design features.

Rotary

Snow blowers of this type are great for clearing relatively large areas, such as home gardens, sidewalks, parking lots, areas in front of a shopping or office center, warehouse complexes, and so on. The main working elements of attachments are a steel body, cutter rotors, helical blades, ejection blades and a chute.

During operation, the rotating cutters crush the snow and the ice edge, the resulting mass, with the help of helical blades, is transferred to the blades, then to the chute, and then thrown in the right direction, at the same distance. With this technique, you can remove not only fresh snow, but also already caked and covered with an ice crust.

fan snow blower

A distinctive feature of this class of equipment is the presence of a fan-type snow thrower. The mechanism of the device consists in raking up snow with special blades and throwing it to a certain distance through the snow thrower sleeve.

Communal brush

This is a universal attachment that can be used at any time of the year. There are 2 main types of brushes - disc and tray. In the first case, it is a plastic or metal disk with plastic bundles (lint) that come out of its end. Nozzles assembled from such discs are mounted on a shaft connected to a hydraulic drive. Unlike the first, tray brushes are a circle made of steel, plastic, less often moisture-resistant plywood, in which special cassettes with metal or polymer bristles are mounted. One of the most popular types of such equipment on the market is the Tornado communal brush.

Screw cleaner

They are the most common, along with rotary ones, and are often a hybrid of these 2 types of snowplow attachments. This is due to high work efficiency and practicality. An auger snow blower is able to cope with snow “porridge” and caked snowdrifts up to 0.45 cm high with an ice crust.

Motoblock with a dump shovel

This is the simplest and most affordable option, the principle of operation of which can be compared with a mini-bulldozer. It is best to use this option with a heavy and more powerful cultivator, but if you wish, you can make a lightweight version that is perfect for medium power motor cultivators. The advantages of working with such equipment are simplicity and accessibility. But at the same time, it should be borne in mind that the blade is attached to the frame of the cultivator, and in the process of work, a fairly large amount of snow is collected on it. The rejection of the latter is carried out by adjusting the angle of fixation of the shovel.

Combined model

Some craftsmen make combined models, for example, a rotary snow blower and a communal brush, but the best option is to combine rotary and fan models and rotary augers, which, by the way, can often be found on sale.

How to make a snow blower from a cultivator with your own hands?

Much of the successful assembly of a snow blower from a walk-behind tractor used on the farm depends on the correct procedure for the manufacturer of the unit. The algorithm of work when assembling the machine should look something like this:

- First of all, the manufacturer must assemble a high-quality and impact-resistant metal support frame. For this, metal pipes are well suited, which must be fastened to each other by welding. Among the pipes used, the manufacturer must have a part with a diameter of 0.5 inches. It must be welded to the frame and used as a handle. The shaft of the working auger can also be made from the pipe. For this, a part with a diameter of 3/4 "is suitable;

- Further, in the middle part of the pipe for the manufactured screw, you will need to make a neat through cut. To do this, the manufacturer must carefully cut a straight line in this part of the pipe, in which a steel plate with dimensions of 12x27 cm will be installed. When operating the snow blower, the plate will play the role of a small blade that will throw away the collected snow masses. This will happen under the influence of the shaft, which, rotating, will create the force required to operate the part;

- In order for the snow to immediately go to the blade, you will need to attach a home-made two-way screw mechanism to it. It can be assembled from the sidewall of a tire or a piece of conveyor belt with a thickness of about 1 cm;

- Next, the manufacturer will need to cut 4 identical pieces from the rest of the conveyor belt, the diameter of which should be 28 cm. To do this, use a jigsaw;

- Then, a platform for the engine will need to be attached to the homemade structure. The platform itself must be quick-detachable, so it must be fixed with metal corners;

- At the next stage, a homemade snow blower shaft from a household cultivator will need to be equipped with sealed bearings. As a result, the diameter of the shaft on both sides should decrease slightly. During the sawing of the shaft ends, the manufacturer must prepare a separate place for mounting the built-in key. To do this, at one end of the pipe you will need to make a groove;

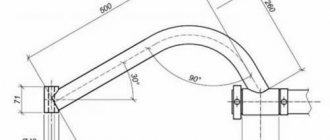

- A homemade snow blower should throw snow away from the operator. To do this, the unit must be equipped with a swivel chute, which can be assembled from a piece of sewer pipe with a diameter of 16 cm;

- To mount the gutter to the base of the machine, the manufacturer must use a small pipe. In the future, she will be responsible for adjusting the direction of ejection of the harvested masses;

- After that, you need to attach the chute to the frame by fixing the pipe on the auger. Then the gutter itself will need to be attached to the welded pipe;

- During self-production of a snow blower from a household motor cultivator, the operator must ensure that the built-in blade is slightly narrower than the diameter of the standard discharge chute. Due to this, the harvested masses will freely pass through the ejection chute pipe and do not accumulate in its internal cavity;

- After that, the finished homemade car will need to be painted. This will protect its metal components from chips that provoke the formation of corrosion.

Manufacturer rating

Currently, there are a large number of models of snow blowers and snow blowers on the market that are compatible with cultivators and walk-behind tractors. Experts have compiled a rating of the most popular and sought-after cars.

Husqvarna

The snowplows of this Swedish brand are popular in many countries of the world. This is due to its reliability, practicality, high performance and ease of maintenance. It can be used even at very low temperatures and extreme conditions, which is explained by the presence of the "Smart Start" function and the rubber auger. Characteristic features of snowplows are:

- Work efficiency even on very dense soils;

- Excellent maneuverability;

- Long service life;

- Compact dimensions;

- Ease of management;

- Remote swivel chute;

- Unpretentiousness in service;

- Reliability;

- Versatility.

Among the most popular models of snowplows from this manufacturer are ST 124; ST 224; ST 324; ST 230; ST 227; ST 427T and some others.

Patriot

The snow removal equipment of this manufacturer combines practicality, efficiency, economy and a high level of safety. These are the main points that are emphasized in the production of equipment. In particular, gasoline engines are designed for a long service life, electric ones have double insulation. The bestseller is the Patriot PS 603 E.

Champion

Snow removal equipment from this manufacturer is widely used by utilities, commercial and municipal enterprises, farmers and individuals. One of its main advantages is high productivity. Added to this is that Champion snow blowers are able to cope with almost any task, regardless of weather conditions. The bestsellers in 2021 were the following models - ST656BS; ST861BS; STT1170E; ST1170E; ST1376E; ST1170BS.

MTD

One of the most famous manufacturers of garden equipment, which also produces a wide range of snowplows (the company was founded in 1932). In the company's catalog, you can choose a snow blower model for various operating conditions, both for small private households and for large industrial facilities and utilities. According to the results of sales for the past 2021. The following models became the most demanded - MTD Optima ME 76; MTD M 61; MTD ME 61.

Hyundai

Hyundai snowplows are in demand among owners of private houses, country cottages, retail outlets. The advantages of snow blowers of this brand are efficiency, practicality, high speed and long service life. This is achieved thanks to:

- The absence of an air filter;

- Carburetor heating;

- Expanded valves (oil);

- The presence of an automated decompression valve;

- Effective protection against overheating.

All this allows you to ensure the productive operation of equipment in the most difficult conditions. For example, heating the carburetor prevents jamming of the dampers due to the formation of ice crystals at sub-zero temperatures. The absence of an air filter increases the efficiency of the engine and increases the efficiency of fuel combustion.

Firework

Snow blowers combine simplicity and reliability of design, affordable cost and ease of operation. The most popular model of this brand is the Salyut SM-0.6, which does an excellent job of removing loose snow and packed masses. Throw distance can reach 10-12 meters. The equipment, as standard, is equipped with a reinforced auger, which can easily cope with ice crust and even debris. Instead of an auger, special knives can be installed. Discarding the snow mass is carried out through a special bell. The drive control elements are located on the steering wheel of the walk-behind tractor, the snow blower chain is covered with a metal casing and is located in the end part. This ensures safe and comfortable driving.

Megalodon

The equipment is distinguished by high reliability, good performance and affordable price. Due to the fact that the auger is made of high-quality domestic steel, of sufficient thickness, it can easily cope even with icy and packed snow. Another plus is versatility - attachments are compatible with most models of walk-behind tractors. The gearbox is characterized by good functionality and a large supply of motor resources. They are equipped with imported engines (6-10 hp), which are easy to start even in severe frosts. This is the best solution for small farms and farms, as well as private households.

Neva MB

Snowplow attachments for the walk-behind tractor of this series are widely used in different regions of Russia. Differ in a simple design and reliable work. All elements are made in the factory using modern technologies and high-strength materials. Thanks to this, high productivity and reliability of the equipment, maintenance safety and ease of management are achieved.

Helpful Tips for Using the Snow Blower

We advise you to adhere to the following recommendations:

- before each use of the device, it is advisable to check the reliability of tightening the threaded connections, as well as the tension of the V-belt;

- after every 6 hours of operation, adjust the chain tension, the amount of deflection of which should be within 10 ÷ 15 mm;

- 30 minutes after the operation of the new snow blower, turn off the engine and check the tightness of the snow blower fasteners.

A modern snow blower for a walk-behind tractor can be purchased both in specialized centers for the sale of attachments for walk-behind tractors, and through online stores. Some craftsmen prefer to make such systems with their own hands, which also has its undeniable advantages. Having the skills to work with metalwork and welded tools, each of our compatriots, if desired and with patience, can make such a mounted unit on their own.

How to choose

Today on the market there is a large and diverse range of models of snowplows, which differ both in price and in their functionality. Therefore, before buying a snow blower motor cultivator, you need to figure out what characteristics you should pay attention to in the first place.

- Type of equipment. It can be a shovel-dump, a communal brush, a rotary, auger, fan snow blower, as well as combined models.

- The area of the site to be cleared.

- Technical characteristics of attachments for snow removal. Here you need to pay attention to what amount of snow cover they are designed for (on average, this figure is 150 - 500 mm), what type of snow it can handle, only with fresh (fluffy) or also with caked and icy, is it possible to adjust the height cut, which drive method - belt or PTO (power take-off shaft), the range of the angle of rotation of the bell through which the snow is thrown.

- Structural features. Weight, overall dimensions, where the control elements of the equipment are located, the reliability of the protection of working elements.

- Compatibility with a specific model of a walk-behind tractor or a cultivator that is already on the farm.

- The material from which the auger, knives and so on are made. Most often, steel or high-strength plastic is used for this.

Also, experts recommend paying attention to the manufacturer of snowplows and giving preference to well-known and time-tested brands.

Principle of operation

The design of a snow blower for a walk-behind tractor is a huge bucket-shovel, which, moving in a given direction, captures the snow mass and transfers it in a thin stream to a screw conveyor (auger). This mechanism is a pair of screws made of narrow strips with many sharp teeth along the edges.

This design makes it possible to connect sections of the auger, and therefore significantly increase the width of the capture.

The screw pair rotates towards the center , where the snow enters. Powerful blades spin with such force that they are able to crush even thick pieces of compressed snow into small pieces. The operation of the screws is designed in such a way that the snow moves very slowly through the mechanism.

This is necessary to ensure the smooth operation of the throwing channel.

DIY manufacturing

For those who do not want to overpay for factory modifications, and understand the principle of operation of equipment, have the necessary materials and skills in plumbing, they can independently make such attachments that will be no less effective than many store products, and often much more effective.

Snow blower from a cultivator rework features

The principle of re-equipping a snow blower from a cultivator with your own hands is to expand the functionality of existing equipment. This can be done in 2 ways.

- Completely convert the cultivator into a specialized snowplow.

- Attached equipment for installation on a walk-behind tractor or cultivator.

The first option is rather complicated and expensive. Therefore, here we will consider the second method.

Preparation of materials and equipment

To realize your idea, you must have the following tools and materials:

- Bulgarian;

- Welding machine

- Drill;

- Hacksaw for metal;

- Spanners;

- Bearings (closed);

- Profile pipes;

- metal corners;

- Steel sheet;

- Plywood;

- A piece of plastic sewer pipe;

- Conveyer belt.

Work should begin with the preparation of a detailed drawing and the necessary materials, according to the chosen design.

Making a snow blower procedure

First you need to make a supporting structure. To do this, a frame is made from metal corners using a welding machine. First, all parts of the structure are connected by spot welding. The field of verification that all dimensions are exactly maintained and there are no distortions, all elements are firmly connected by a continuous weld. The screw shaft is best made from a steel pipe with a diameter of 40mm. In its middle part, using a drill, you need to make a through hole to install a metal plate. The latter will perform the function of a shovel, which, when the shaft rotates, will throw snow in the direction selected by the operator. For the manufacture of the handle, you can use a pipe with a diameter of not more than 20 mm.

In the process of work, snow masses will not immediately flow to the shovel. Their supply will be carried out using a 2-input auger. To make it, you will need a conveyor belt, from which you need to cut 4 rings with a diameter of 280 mm. You can also use the side of the old tire for this.

The platform must be strong and secure enough to support the cultivator's engine. Between the power unit and the platform you need to lay a thick rubber mat that will reduce vibration. The platform is made as follows - 2 metal corners are welded to the pipe and then this structure is fixed at an angle of 90 degrees relative to the blade.

The next step is to install sealed bearings into the shaft. To perform this operation, you need to saw through the ends of the shaft a little and tap with a hammer. In addition, you need to prepare a groove for the key on one side of the shaft.

The ejection of snow mass from the structure will be carried out through a rotary chute. It can be made from cutting a plastic sewer pipe with a diameter of at least 160 mm. This is necessary to ensure free movement of snow along the gutter, if the diameter of the pipe is smaller, then snow masses may be delayed during operation.

To securely fix all the elements on the frame of the mounted snowplow, a pipe must be welded to the auger. The gutter is attached to a ready-made and assembled structure. The direction of snow mass ejection will be adjusted through a cut of a plastic sewer pipe.

An important point is that the blade width should be 20-30 mm less than the diameter of the discharge chute. This will ensure a quick removal of snow from a homemade snow blower.

To facilitate the movement of equipment on slippery surfaces, it is necessary to install skis on it. Usually, thick plywood is used for this, preferably moisture resistant. Plastic strips can be additionally installed to the bottom surface of the skis. Thanks to this, the movement of equipment will be smoother and faster.

All metal structural elements must be painted. This will protect them from corrosion. Especially important, given that the equipment will be constantly operated in conditions of high humidity.

Before starting work, the assembled snow blower must be carefully checked. In this case, special attention should be paid to all connections and attachment points of the structure. Then introduce lubricants and fill with fuel. Next, start the engine and let it idle for 5 minutes. When the power unit warms up a little, you can test the snow blower in operation. It is advisable to do this on a site with fresh (not packed) snow. When working, you need to pay attention so that the cultivator snow blower does not make unnecessary noise, does not smoke excessively and does not overheat. If the first test goes well, you can move on to areas with denser snow cover.

Instruction

- The snow blower frame can be made from metal corners using the welding method. A pipe that takes about half an inch can be fixed and used later as a handle. The auger shaft can also be made from a pipe, however, for this it must take up three quarters of an inch.

- In the middle part of the pipe, a through cut should be created, that is, a straight line should be cut through. It is necessary to install a metal plate, which in turn should have the following dimensions: 12 by 27 cm. This metal plate is often called a spatula.

- It is necessary for throwing snow. Performs this function due to the rotation of the shaft during operation of the device.

- When hit by a snow blower, the snow does not immediately reach the place where it can be caught by the shovel. A two-way screw should move it to this element. To create it, you can use the sidewall of a tire or a conveyor belt 1 cm thick.

- You need to stock up about half a meter of this tape, then cut 4 rings out of it with an electric jigsaw 28 cm in diameter.

- It is necessary to attach a platform of a quick-detachable engine to the structure, which can be taken from a walk-behind tractor. To do this, attach metal corners to the pipe by welding. They need to be placed perpendicular to the plate.

- The shaft should slide easily into the sealed bearings. To do this, you need to saw through the matter several times at its ends, and then tap them. If this action is carried out correctly, the shaft diameter will decrease slightly. You should also create free space for the key, so a groove must be made on one side of the shaft.

- For smooth and as fast as possible movement on the snow, it is desirable to leave the device without wheels. It is appropriate to replace them with skis. Making them yourself is very easy. It is enough to cut out the bases from wooden bars.

- Plastic strips should be attached to them so that the structure slides as smoothly as possible. You can also save on these elements by replacing them with special boxes that are often used when installing electrical wiring.

- The snow is thrown away directly by the swivel chute. At home, it can be made from a sewer pipe whose diameter is greater than or equal to 16 cm.

- To attach a rotary chute to the base, a pipe with a small diameter should be connected to the auger, and this structure should be welded to it.

- The rotary chute, in turn, is equipped with a small section of the sewer pipe, which acts as a regulator of the direction of movement of snow masses during ejection.

- When arranging the structure, it is necessary to ensure that the width of the auger blade is necessarily less than the diameter of the chute.

- So you can ensure the free removal of the snow mass without delays or clogging of the working hole.

- To make the design look aesthetically pleasing, it is enough to paint it. Do not neglect the need to paint over all the details. It is advisable to choose a bright paint, you can also use your imagination and make designer ornaments on a snow blower.

- When all work on the manufacture of the snow blower is completed, the product should be tested. Since then, the device is completely ready for operation and can be actively used during the entire winter period.

The simplest do-it-yourself Mole snow blower

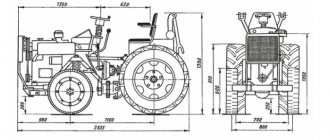

This type of construction is carried out in the presence of a factory walk-behind tractor engine. It is advisable to create in advance drawings of parts that are suitable in size, indicating their parameters, so that in the future there will be no problems with the preparation of original samples.

See the video below for more details:

To make a simple do-it-yourself snow blower, you need to have a TV-6 lathe, sheet steel and a welding machine. You can not purchase a lathe, but in this case you will have to order all the parts from a professional turner.

Homemade circular sawmills are very popular among site owners, because they can easily cut a log of any thickness.

The Shacman dump truck from a Chinese manufacturer costs much less than its counterparts, but does its job no less well. Find more detailed information here.

Useful tips on how to choose a petrol lawn mower can be found here //machinspec.com/kommunalnaya/kosilka/vybrat-benzinovuyu.html.

When creating a snow blower with your own hands, you need to consider that its main part is the auger. To make it, you need a pipe with trunnions on both sides. Eight half-disks should be welded to the structure, which in turn are cut from sheet steel 2 mm thick. For more information on how to make a snow blower auger with your own hands, you will find in this article.

With their help, a kind of two-way spiral is formed. All points of contact of the rings in the spiral must be welded with high quality in order to avoid deformation of the product.

The screw spiral can be welded not only from disparate half rings, but also from two parts. To do this, you need to cut the elements on each side, wrap them and fasten them so that you get a full-fledged spiral.

If the creation of the screw is difficult or the person has no desire to do it with his own hands, you can use a ready-made device. The best option would be an auger left over from old agricultural machinery, but in good condition.

To activate the rotation of the auger, ball bearings No. 203 are required. The bodies are made in the form of cups made of aluminum AMgb or AMg3. They should be attached to the sides of the snow blower using Mb bolts, tighten them with suitable nuts. With this design, snow will be fed to the rotor.

The rotor itself works inside the drum, which you can make yourself from an aluminum boiler with a capacity of 20 liters. It must be fastened to the front wall of the equipment case using 4 mm rivets. The mechanism works very simply: snow falls into the drum, and then is thrown by the blades to a distance of 3-5 m.

The distance of the snow mass departure depends on the parameters and the quality of the internal configuration of the device).

An important aspect is the creation of torque, which must pass from the walk-behind tractor to the snow blower design. In a walk-behind tractor, torque is transmitted from its engine to a shaft, which must be connected to the snow blower's shaft.

For this, a V-belt connection is used.

To organize this mechanism, it is necessary to select an A-100 belt, as well as a pulley adapted for it.

The body of the snow blower, according to the standard, is made of steel sheets 2 mm thick. The corners are made in the proportion of 2 by 2 cm. They should be fixed with rivets 4 mm in diameter, the structure can be strengthened with M4 screws.

It is advisable to put the structure not on wheels, but on skis, since with their help the snow blower will not only move easier and faster, but the owner will also be able to control the height of snow clearing. However, if you have enough finance for the unit in your reserve, then it’s better to take a closer look at the Champion 656 self-propelled gasoline snow blower, which will significantly facilitate the work and make it safer for you.

Some Tips

During the operation of a homemade snowplow, you need to monitor the road surface. To do this, you must first walk through the areas and remove branches, plastic bottles, stones and other debris. If this is not done, then solid foreign objects can get into the auger and disable it.

Periodically, it is required to control the quality of the lubricant and, if necessary, replace it. It is recommended to change the oil 2 times a month, with regular use of the equipment. Observing these simple conditions, a home-made snow blower will work effectively for more than one season, significantly facilitating the work of caring for the local area or suburban area. At the same time, its maintenance will be as economical and comfortable as possible.

Step-by-step instruction

Starting the process of creating a snow blower from a cultivator with your own hands, you need to draw up drawings and follow a step-by-step guide. This will allow the invention of a reliable snow blower that will perform its tasks without failure for many years. Step-by-step manufacturing instructions consist of the following steps:

- First you need to create a frame for the future cleaner by welding pipes from any thick metal to each other. To make the structure reliable, it can be reinforced with steel corners. For the manufacture of the handle, a separate pipe, 20 mm thick, is used, and for the shaft of the screw mechanism, a pipe with a diameter of 5 cm is used.

- Next, it is necessary to cut a through cut inside the auger pipe in order to install steel plates in it, 17x27 cm in size. The device is used as a blade, which rotates under the influence of the shaft and pushes the snow masses in the auger mechanism.

- To ensure the free passage of snow to the bucket, the device is equipped with a 2-way auger. It is made from a 1 cm thick conveyor belt or from the sidewall of a rubber tire of an automobile wheel. 4 ring-shaped parts with a diameter of 28 cm are required.

- A platform is welded to the supporting base of the snow clearer. It will be used to install and mount the motor from a walk-behind tractor or cultivator. Installation is carried out by welding a steel plate with a thickness of at least 10 cm to the frame. Steel corners are used to strengthen the welding site.

- Next, you need to install sealed bearings in the inner cavity of the shaft. This is done by sawing the ends of the used shaft with a file and tapping the bearings with a hammer. When performing such actions, care must be taken, otherwise the shaft may be damaged and its thickness reduced. It is also important to provide a place for mounting the key by making a small groove at the end of the shaft.

- To achieve smooth and uniform movements, the snow blower is equipped with a set of skis. This design is easy to make with your own hands from wooden bars. A plastic panel is fixed on the bottom of each ski to ensure smooth movements.

- The role of the snow thrower in the snow plow is performed by a rotary mechanism made of a sewer pipe with a thickness of 160 mm or more. The part must be connected to the auger mechanism.

- Further, a pipe segment is welded to the rotary chute to change the direction where the snow will be thrown.

- At the stage of mounting the working units on the frame, it is necessary to ensure that the blade is slightly thinner than the rotary chute. This will ensure that snow is thrown away without any delay inside the mechanism.

- At the end, it is necessary to complete the decorative part of the work, paint the metal parts with an anti-corrosion coloring compound.

shovel blade

The simplest option for a snow blower cultivator is a blade. And although it is more expedient to use such a design for motoblocks with a more efficient motor, in the case of a motor cultivator, a simplified model with reduced weight can be invented.

Working with such attachments is characterized by simplicity and accessibility. The blade is fixed on a bracket to the cultivator frame, and during the operation of the equipment it accumulates snow masses.

To throw snow to the sides, the shovel is fixed at an angle.

In the manufacture of the blade, a steel sheet having a thickness of 3 mm is used. To give it the desired shape, you need special equipment. If possible, it is better to find a piece of steel pipe with a diameter of 2-3 cm, cut it in half, and then divide it into 3 parts.

The lower element will act as a knife and cut layers of snow.

Rotary hitch

To make a rotary snow blower, you will need to show some skills in turning and welding. Such a hitch is also called auger, because. an auger is placed on its internal bearings.