- home

- Fuel

- …

I continue to reveal the topic of gaseous fuels, we have already talked about methane and propane , about generations of LPG , but today there is another topic that is only gaining momentum. Let's talk about the gasification of a diesel engine, yes, GAS for diesel! Say - "this is not possible"! You just don't know how to cook it! I’ll tell you everything, from the principle of operation to the cost of equipment, there will also be a video, so we read (watch), it will be interesting ...

Actually installing gas-balloon equipment (HBO) or not is everyone's business, by the way, it is not always beneficial for personal use, a car ( details here ). But for owners of commercial vehicles, it can bring tangible benefits. Of course, if you say a taxi driver, or drive with a freezer van, roll 300-600 kilometers a day, HBO will pay off for you after three to four months of work, and then it will only make a profit. After all, methane or propane is much cheaper than gasoline or diesel , about two times cheaper. And modern HBO systems allow you to spend (almost) as much gas as liquid fuel, the difference is in percentage.

Options for installing LPG on diesel

The ignition of fuel in a diesel engine occurs in the combustion chamber due to its injection under pressure into compressed air.

Therefore, two technical solutions are currently being used to put conventional gas equipment on any diesel engine. The difference between them is fundamental:

- Complete conversion of the engine to an electric / spark ignition system (improvement of the CPG, timing, cylinder head, change in compression ratio due to possible detonation), where the gas will be ignited by gasoline candles. Technical changes will be irrevocable and completely eliminate the possibility of using D/T. This is a very expensive change that will require not only the involvement of highly paid professionals, but also complex engineering calculations. In private transport, this is extremely rare. The most successful examples are only factory-made gas engines (KamAZ, Scania, YaMZ, Iveco), which operate only on methane.

Tractor Iveco on gas

- Modernization of the vehicle by installing additional equipment, after which it becomes possible to use two types of fuel, diesel fuel and gas, the so-called Dual Fuel system or gas diesel. This is the most popular and cost-effective way, does not require permanent changes in the system. Such a car cannot run on gas alone.

There are also factory models of gas-diesel engines running on methane. For example VOLVO (Volvo) FH / FM and KAMAZ 5490 NEO with a Mercedes-Benz power plant. But such machines have not yet been widely used.

Trucks with factory diesel

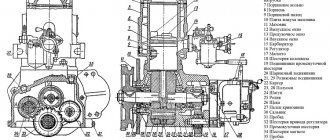

The principle of operation of a gas-diesel engine

The transition to gas fuel is carried out using a switch from the passenger compartment of the car after the engine has warmed up, or automatically. The process of gas supply is controlled by the electronic control unit of the HBO installation.

Gas is supplied to the diesel engine in a dosed manner using injectors into the intake manifold. From where, mixing with air, on the intake stroke, it enters the cylinders through the intake valves. Then diesel fuel is sprayed into the gas-air mixture compressed by the piston (compression stroke), where, due to pressure and temperature, an explosion occurs. D / t here acts as a fuse, since the ignition temperature of the gas is higher than diesel fuel and it itself cannot ignite.

HBO on a diesel engine - the principle of operation

It is worth talking more about how diesel works on gas.

Principle of operation:

- The gas flows from the cylinder to the gas valve.

- Next, the gas is cleaned in the valve filter and passes to the reducer.

- The propane evaporates and the methane expands.

- The gas enters the mixing chamber before the nozzles.

- The gas is sent to the combustion chamber. It mixes with diesel fuel and air, after which it ignites.

The electronic control unit is responsible for the fuel supply, receiving signals from standard and additionally mounted sensors.

Types of fuel that can consume diesel on gas

Converting the engine to a dual fuel system is possible only for a specific type of gas. Either it will be methane, or a propane-butane mixture.

It is more expensive to make a methane diesel, but it will perform better economically than the propane version. Plus, methane is cheaper. When propane is supplied to diesel, the contribution to the total fuel consumption will not exceed 30-50%. But the share of consumption of the methane component can be increased to 80%. It all depends on the mode of operation of the internal combustion engine, which takes into account:

- vehicle speed;

- season (summer, winter);

- load on the vehicle;

- terrain (mountains, plains);

- gas pressure and temperature;

- turbocharged diesel or not.

Diesel equipment options

Vehicle equipment for methane and propane is different.

Diesel on methane is suitable mainly for large vehicles due to the difficulty in the location of the cylinders. Passenger cars are more often equipped with propane, in addition, it is liquid, which simplifies its adaptation to cars.

There are two main options for such re-equipment: full and gas-diesel.

Complete refurbishment

The installation of this option is used when equipping a car for methane. The engine needs a major overhaul, after which it will be able to run only on gas.

The ignition of methane occurs at a temperature twice as high as it is necessary for diesel fuel. It needs such a strong compression, otherwise, it will not light up at all.

For the system to work properly, the compression ratio is reduced and an ignition system is installed. This is true for both propane and methane diesel engines.

A complete re-equipment also involves the installation of a metal gasket under the head. Spark plugs are mounted in place of diesel injectors, and gas fittings cut into the intake manifold.

After such a radical change, it will be difficult to return the motor to its original state. Diesel will no longer be called diesel, since it will not be able to work on diesel fuel.

Gas diesel installation

Gas diesel has become widespread. This is the best option for working on propane-butane. The engine can run on diesel fuel or on a mixture of gas and diesel fuel. It will not work on clean gas.

Gas on a diesel engine is not much different from mounting a conventional HBO.

The principle of operation of a gas diesel engine:

- Gas enters the cylinder during the intake stroke.

- Diesel fuel is injected at the end of the compression stroke, after the formation of a gas-air mixture in the cylinder.

- All this ignites.

Advantages and disadvantages of converting diesel to gas

The main advantage of installing HBO for methane, or a propane-butane mixture for a diesel engine, is a reduction in fuel costs from 10-50%. Besides:

- there is an increase in efficiency, motor resource. At the same time, power and torque remain the same, or increase, in some cases, by 5-25%;

- the service life of the standard fuel system is increased by 1.5-2 times (a big plus for Common Rail systems); harmful exhaust emissions (smokyness) are reduced;

- the gas engine runs softer, its noise is reduced;

- lowering carbon deposits, deposits in cylinders, combustion chambers, particulate filters;

- reduce the cost of replacing engine oil;

- the mileage of the vehicle increases with a dual-fuel driving mode; no engine modifications required.

Of the serious shortcomings:

- high cost of refurbishment;

- increase in time and costs for maintenance, configuration, and repair of the system;

- search for places for attaching cylinders, reducing the useful volume due to them;

- increase in vehicle weight.

Gas-diesel on methane and on propane-butane

If the conversion technology is not followed properly (for example, incorrect installation or the absence of a temperature sensor on the exhaust manifold), the wear of the power plant can significantly increase. Since a high temperature begins to form in the combustion chamber and exhaust system during the explosion of the gas-air mixture and diesel fuel.

Diesel Features

A diesel engine has a number of features of operation, unlike a gasoline one.

The main differences relate to mixture formation and ignition:

- The fuel-air mixture is formed in the cylinders.

- Initially, air is supplied to the cylinders, then diesel fuel is injected.

- Diesel fuel ignites under the influence of temperature or compression pressure.

- A spark is not needed, as there is no ignition system.

The design of a diesel engine may imply: a separate combustion chamber and injection.

It is believed that the fuel device of a diesel engine is more complicated than a gasoline one. This is because a diesel engine requires precise timing, volume, and pressure.

To facilitate cold starting, glow plugs are used. They pre-heat the air in the combustion chamber. There can be 2 pumps - high and low pressure.

All these features indicate the dubious possibility of installing HBO on a diesel engine.

Diesel vehicles that can be converted to diesel

Any diesel engine can be converted to use gas as an additional component. It does not matter what type of fuel system is used as a base, a mechanical high pressure fuel pump (high pressure fuel pump), pump injectors or a common rail rail / rail. Also with on-board network 12/24 V. With turbine or atmospheric.

At the same time, the cost of modernizing a car will be significantly less than the cost of reworking a truck engine, due to the number of installed cylinders, fasteners and multi-valves for them or valves in the case of methane. Also, for engines with a large volume, 2 gas reducers are used.

They will also have different payback rates. The higher the consumption of diesel fuel, the greater the savings from the use of gas. For passenger cars with low daily mileage, the cost recovery for installing LPG is stretched for many years. In this sense, commercial vehicles that make long regular trips win more. The payback period of such machines is 3-12 months.

Also, the answer to the question of whether it is profitable to switch to an alternative type of fuel or it is better and more economical to leave “clean” diesel depends on the nature of the operation of vehicles.

Gas equipment for a diesel engine installed at the factory

Factory installation of methane equipment is the most reliable option, since it takes into account the characteristics of the motor. But there are also a number of disadvantages:

- a limited range of models that have this option;

- high price of factory modification.

Major automakers create similar products, fully considering the principles of operation of a modern diesel engine on gas:

- a reliable electronic control system is mounted, as a rule, premium manufacturers are used;

- a network of sensors (crankshaft, synchronization, detonation, gas reducer and exhaust temperature, gas pressure, accelerator pedal).

Factory gas-diesel provides the highest fuel savings with full preservation of the technical parameters of the vehicle.

Gas engine - a fundamental change in the engine

A radical way to transfer a diesel engine to work on gas-balloon equipment, involving a major change in the engine:

- installation of spark plugs, which will serve as injectors;

- installation of an ignition system instead of fuel equipment;

- removal of "unnecessary" metal on the bottoms of the pistons or in the combustion chambers in order to significantly reduce the level of gas compression.

Such a gas installation on a diesel engine, in fact, means a complete change and the transformation of the diesel “heart” of the vehicle into an all-gas engine. In terms of its parameters, it will be very similar to a gasoline internal combustion engine “pressed” for gas (quite economical - gas is cheaper than diesel fuel, environmentally friendly - it does not pollute the atmosphere so much, with an increased service life).

This option of converting diesel to gas is being actively implemented in the countries of the European continent. But in the CIS and Russia, motorists are much more likely to follow a different path, involving the receipt of gas diesel. About him further.

The difference between HBO configurations for diesel and gasoline engines

In general, the main difference between installing HBO on a diesel engine from a gasoline engine is the use of a special electronic control unit (ECU for diesel fuel) and the placement of temperature sensors on the exhaust manifold to control and prevent overheating of engine parts.

In addition, on vehicles where a mechanical injection pump is used, an electromechanical actuator , which limits the supply of diesel fuel . In modern systems, this function is implemented by emulating the signals of an electronic gas pedal .

Installation of HBO on diesel in a car service

Not all companies specializing in the installation of automotive LPG equipment take on such orders. Only those who have certain knowledge, experience in this area and technical capabilities for re-equipment agree. And if the question concerns heavy equipment, there are even fewer competent specialists.

We talked about how to choose the right installer here.

Propane and methane tractors

But regardless of whether it is necessary to install HBO on diesel trucks, light vehicles or agricultural equipment (tractors, etc.), with the proper approach, the economic effect will be obvious .

Is it possible to convert diesel to gas with your own hands

It is impossible to put all the additional devices on a diesel power unit yourself without a serious tool base in a personal subsidiary plot, or a garage. The most time-consuming operations are:

- Connection of gas equipment.

- Adaptation/synchronization of standard fuel system.

- Installation of instrumentation and electronics.

In addition, you will need special software to configure and adjust the system. But if there is a strong desire, re-equipment is possible.

It is important not to forget about the mandatory registration of an additional fuel installation, which is not a quick procedure. Where relevant documents from the service station are also required.