Does your company need to assemble lifting equipment in a short time? Are you looking for a quality faucet installation at an affordable price? Our company carries out assembly and installation of any industrial lifting equipment, as well as crane and crane runways. We have the required permits, regulatory and regulatory documentation to solve such a technically complex production process as installation. Our qualified specialists will assemble the crane in the shortest possible time so that the employees of your production begin to directly perform their tasks.

Briefly about overhead cranes, purpose and classification

The bridge crane is a means of small-scale mechanization and is designed to perform loading and unloading operations. The crane device is represented by the following elements:

- grab or hook suspension;

- working strokeused to move goods, as well as to unload them;

- idle , which serves to return the empty load gripping device to its original place where the cargo is received.

As for the classification of overhead cranes, there are a lot of them:

- bridge cranes of general purpose;

- special overhead cranes;

- overhead metallurgical cranes;

- mine overhead cranes.

Most often, overhead cranes are used in repair shops, in factories in various industries, in the construction industry as a whole.

What is the cost estimate for installation?

The estimate for the installation of an overhead crane includes a complete list of the work that was carried out, regardless of whether they indirectly or directly related to the installation of the structure. The scope of work itself directly depends on the installation method, which experts determine based on specific conditions.

The method of installation will be greatly influenced by the mass of the crane, as well as its design.

The location of the installation and the degree of readiness of the construction object will contribute a significant share in determining the final cost of the work. When drawing up estimates for installation, great importance is given to the design features of the building, the species composition of the fleet of lifting machines available to the customer.

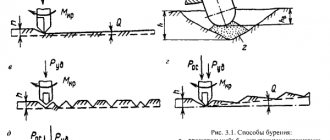

If we talk about the most popular methods of installation of overhead cranes, then these are:

Overhead crane installation process

- installation by means of jib self-propelled cranes;

- installation with tower cranes;

- installation using jib rail cranes;

- installation based on the structural features of the building frame;

Often, with intensive use of an overhead crane, you have to deal with its repair. Minor repairs are carried out in the current mode, and major, as a rule, requires a special organization. Therefore, there is such a type of estimate as an estimate for the repair of an overhead crane. It will include a list of works, including:

- dismantling of the crane or its strategic part in need of major repairs;

- washing of parts, cleaning and washing of mechanisms and important components;

- replacement of broken or worn parts;

- checking, repairing or replacing fasteners;

- assembly and testing (running) of the mechanism.

Stages of installation of an overhead crane

The process of installing an overhead crane-beam includes the following main steps:

- Preparation, coordination and approval of the project with the calculation of the carrying capacity.

- Assembly of metal structures of the crane and installation of lifting equipment.

- Installation of the power supply system of the lifting mechanism. For this, cable networks of current supply are laid, grounding of crane runways is necessarily provided.

- Commissioning with setting the operating parameters of the equipment. Be sure to carry out tests with lifting and lowering the load.

- Preparation of reporting documentation after installation is completed.

When installing overhead cranes, special attention must be paid to crane runways, they must comply with building codes and working documentation. Compliance is confirmed by the act of acceptance. On the crane runways, there must be limiters that prevent the mechanism from derailing the rail.

What to pay attention to when installing a faucet

Performed by the company "TekhKranMontazh" High-quality installation of an overhead crane is the key to further uninterrupted and efficient operation of the crane. It is at the time of construction that special attention should be paid, since in this process not only the mechanism itself is laid, but also the basis for its high performance, as well as the duration of the operating period of the lifting equipment.

Installation work (just like the dismantling of an overhead crane) should only be carried out by specialists. As a rule, this type of work is carried out by specialized companies that have a documented right to install cranes. Overhead cranes belong to the mechanisms of the increased danger class, therefore it is extremely important to observe safety precautions, both during installation and during operation.

The video shows the installation process of a single-girder overhead crane

Great importance should be given to the choice of a company that will install lifting mechanisms. Among the main features, it is worth highlighting the availability of all documents allowing the installation, configuration and start-up of mechanisms, the availability of high-quality special equipment for installation, a staff of highly qualified specialists with experience in carrying out such work.

Installation

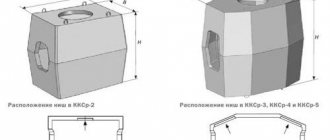

Installation of a double-girder overhead crane is carried out taking into account the following indicators:

- Technical characteristics of the crane (weight, maximum lifting height, overall dimensions, wiring diagram).

- The dimensions of the room or workshop, the bearing capacity of the walls or columns on which the crane runways will be installed.

- Conditions for assembling the structure (availability of access roads and installation site).

There are several methods for assembling a crane. Single-beam lightweight structures are mounted below. Then the finished structure is lifted up using auxiliary equipment and installed on the rails. Installation of the structure includes a large number of operations, especially when assembling devices with a load capacity of 50-100 tons and more.

Stages of installation of a double-girder crane:

- Half bridges are being installed. At the assembly site, 2 halves of the bridge are assembled.

- They assemble and install the end beams on the crane runway.

- Half-bridges are lifted and mounted on ring beams.

- Connect half-bridges and end beams together.

- Carry out the installation of the trolley movement system. Then they lift it up and fix it on the bridge.

- The power supply unit and the device control system are assembled.

- Mount the limit switch.

- Carry out the assembly and installation of the operator's cab.

- Perform adjustment work. Test the installed lifting device.

Types of installation of overhead cranes

All work on the installation of an overhead crane is normatively fixed in the requirements of GOST, SNiPa, RD 10-138-97 and PB 10-382.

According to these regulatory documents, the following types of installation are distinguished:

- Complex , including the installation of crane tracks first, and then the assembly of lifting equipment directly.

- Partial , implying the installation of an overhead crane on already installed crane tracks. It takes into account the fact that the crane runways with this type of installation require mandatory additional leveling, in accordance with the regulatory requirements of the above documents.

The stages of installation of an overhead crane include the following steps: study of the installation site of the crane in order to carry out the necessary calculations and find the optimal way to assemble the mechanism. In full accordance with the data received, a PPR is being developed, the abbreviation of which stands for " Project of Production Works ". This document formulates key technological solutions regarding the installation of lifting equipment.

The main types of installation of lifting equipment

The installation of cranes must be carried out strictly in accordance with GOSTs and SNiPs. Lifting equipment is installed in two ways:

- complex;

- partial.

An integrated view consists in the installation of crane runways, and then the assembly of the structure itself takes place. This type is used in new buildings, as well as in those objects where lifting equipment has not been used before. Before starting work, calculations are carried out, a project is drawn up.

Partial technology involves the installation of crane equipment, subject to the availability of crane tracks. Before starting work, the elements are carefully checked for corrosion and other damage. Crane tracks undergo additional testing in accordance with regulatory requirements.

Installation of crane equipment involves a thorough study of the site. It is necessary to carry out the necessary calculations to draw up a project and determine the optimal method of fastening the elements. In addition, a production plan is being developed. It spells out all the recommendations for the installation, repair, operation of equipment, and also identifies the main technological solutions.

Which mounting technology to choose

The installation technology completely depends on the weight and dimensions of the installed equipment, as well as on the features of the building or the layout of the premises, workshops and warehouses.

Also, the choice of installation technology is influenced by the area of the installation site, the method and sequence of work on the assembly of the crane.

Features of installation of overhead single- and double-girder cranes provide for three approaches to execution:

- Element-by-element type of installation , which implies the assembly of structural parts not on the ground, but directly on the working site of the hoisting mechanism section. To do this, all parts are raised to the installation site. The inconveniences of this installation technology are obvious, but its use is advisable when there is not enough free space (some elements of the crane are still quite large and have a large mass of mechanisms, assemblies and metal structures, especially if it is a double-girder crane).

Installation of a double-girder crane with a lifting capacity of 200 tons

The composition of the element-by-element technology for assembling an overhead crane is as follows: alternate lifting of half-bridges and their connection, mounting the crane trolley, analyzing the geometric dimensions of the structure in the assembly, installing the operator's cab and reeving the ropes.

- Large block type of installation. Assembly using this technology involves the installation of individual block structures on the ground - electrical equipment, components and mechanisms of the crane. Then the complete and assembled units are lifted to the installation site of the lifting mechanism and assembled into a single whole. Thanks to this technology, the number of dangerous assembly operations at height is significantly reduced, and the installation process as a whole is several times faster. Unfortunately, the technology is not suitable for buildings that do not have enough space for the assembly of large structures.

- The full block type of installation consists in assembling the crane bridge completely in the lower position, that is, on the ground. The finished crane bridge is lifted for installation on the crane tracks. At the same time, installation specialists have a choice - to install the load trolley together with the bridge or separately.

Thus, it is obvious that the most promising and profitable plant technologies are large-block and full-block. They reduce the number of operations that need to be carried out at height, it is possible to use lifting equipment, as well as shorter deadlines compared to element-by-element assembly technology.

Choice of overhead crane installation technology

When choosing one or another installation technology, specialists take into account, first of all, the mass and dimensions of the future equipment, the design features of the building and the layout of the installation site - premises, workshops, warehouses.

Installation of an overhead single or double girder crane can be:

- Element by element - the assembly of the elements of the crane installation is carried out at the place of installation of the crane equipment. This type of installation has its own characteristics and is considered quite inconvenient - it is used only if there is an acute shortage of free space on the work site. The half-bridges are lifted and connected in order of priority, then the crane trolley is mounted, the geometric dimensions of the assembled structure are analyzed, the driver's cab is installed and the ropes are loaded - the process is complex and requires precision and utmost concentration of attention from the performers.

- Large-block - block structures (electrical equipment, components and mechanisms) are mounted directly on the ground. Then they rise to the platform where the installation of crane equipment takes place and are assembled into a single whole. This type of installation is faster, safer and more convenient. However, where assembly places have space restrictions, it is not possible for technical reasons.

- Full block - the crane is assembled entirely directly on the job site. The finished crane structure is placed on the crane tracks. The only thing that the specialists have to decide is how to mount the cargo trolley - separately from the crane or together with it.

Most often, for the installation of an overhead crane, large-block or full-block methods are used, as they are more profitable from an economic and temporal point of view. In addition, these are the most technologically advanced and safe options - they allow you to reduce the number of high-altitude operations, provide the opportunity to use lifting equipment and minimize the time frame for the implementation of work.

Features of installation of crane tracks

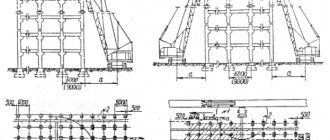

Features of the runway run directly depend on the type and individual distinctive characteristics of the lifting equipment. There are the following types of execution of the crane runway for overhead cranes:

- a complex of crane beams attached directly to the load-bearing structural elements of the premises;

- a supporting crane runway installed on the supporting columns of the building;

- overhead crane track attached to rafters, reinforced trusses;

In general terms, the installation of crane runways is as follows:

- A road project is being developed;

- A thorough examination of the proposed installation site is carried out;

- PPR is being developed;

- All necessary elements of metal structures, fasteners are supplied;

- Crane beams, rails are mounted;

- Crane runways are being leveled.

Installation of crane tracks - features of the work

Crane tracks are called a whole complex of guides that serve to move crane equipment. For their manufacture, high-strength wear-resistant metals are used - crane runways must withstand high operating loads.

Crane tracks consist of:

- Columns or rafters for supporting overhead cranes.

- A beam for a crane track for moving a trolley with a cargo device and a driver's cab.

- Track equipment - signs, traffic limiters, warning signs.

- Guides and fasteners at the joints.

Before proceeding with the installation of crane runways, their project and PPR are developed, an examination of the installation site is carried out. Further, elements of the future structure are supplied, crane beams and rails are installed, crane tracks are leveled.