The first stage in the construction of a building has always been, is and will be the stage of building a foundation and, accordingly, driving piles. This stage is most strongly associated with the features of the relief and structure of the area. How well you complete this stage will depend on all subsequent construction and operation of the building.

Later I will try to consider the full sequence of the pile foundation. Starting from planning and ending with rare ways of doing work. In the same article, we will talk about the "grandfather" method - driving ready-made piles, made at the factory and brought to your construction site.

We start with the fact that the piles are already at hand, the foundation pit has been dug, at the catch. The first thing we need to do is install the pile in the design position. Roughly speaking, stick into the ground in the right place. Piles can be transported around the construction site in several ways:

- Small faucet;

- Koper.

Of course, you can use some kind of pile movement, but with the help of the latter it is quite difficult to complete the next step - aligning the pile vertically. In fact, a crane is not even needed for this, but the crane itself will also be needed for the further construction of the building, but the pile driver is a highly specialized special equipment and can do nothing but drag and hammer piles.

They dragged the pile, put it in the right place, stuck it into the ground. Then we go from simple to complex.

Everyone knows this rumbling machine. If we consider the construction sites of the 70-80s, then there was practically no alternative to the diesel hammer. The noise from his work is one of the main disadvantages. It is worth noting its greatest impact on the ground, but more on that some other time. The advantages include clearly low cost and independence from other construction equipment.

Yes exactly. The diesel hammer device allows the pile driver or crane to leave the pile alone and move on to the next one on the list. This greatly saves time resources.

Let us dwell on the principle of operation of a diesel hammer in a little more detail. Under the action of its own weight, the head or “woman” rushes down towards the pile, increasing the pressure in the working cavities. In the event of a collision in the working cavity, the fuel-air mixture is detonated, the "woman" and the pile seem to be pushed apart in different directions. The pile sinks, the “woman” is thrown up and all the energy in the cavities is released. Upon reaching the "woman" top, the exhaust valves open and the exhaust gas mixture is thrown out. At the same time, new air is taken in, the "woman" begins to descend and the process of pile driving resumes.

A hydraulic hammer is not an independent construction equipment, but an attachment to a pile driver.

When using it, fuel consumption and noise from work are significantly reduced. We pay for this with time. The pile driver will not be able to drive another pile until he has completed this one.

This is also a nozzle for a pile driver, but its operation is based on a different principle. The property of the soil to "spread apart" under the action of vibration is used. The vibratory driver is equipped with eccentric pendulums that swing the pile until it is loaded, i.e. clogged.

This allows you to significantly reduce effort and noise, but again we pay for this with time.

When working on a pile-pressing installation, a pile driver is no longer needed. Usually, a small pile is already installed on it for feeding piles. Piles are fed into a special clamp located in the center of the installation. The forces applied to the pile are enormous. In order for it not to turn over, plumb lines are needed. At the same time, the weight of such a self-propelled unit becomes very large.

Of the main disadvantages, it is worth noting the need to assemble and disassemble the installation during its transportation and, of course, the weight.

We often meet with the mention of a pile foundation, in relation to low-rise construction. The basic principles for the construction of such a foundation are clear, but here's how the piles are driven into the soil and how this process takes place, these are the questions that fade into the background, and we'll talk about them today.

It is one thing when we can independently install the rods at the construction site, by the way, we will also talk about this today, and another thing when we need special equipment for this.

Piles and the foundation process

Where and in what cases special equipment is used

First of all, driving piles is necessary for problematic soil.

Let's explain this:

- High location of groundwater.

- Heterogeneous soil, and the layers can occur both dense and crumbly.

- Marshy terrain where you need to get to dense layers of soil.

At the same time, for example, in low-rise construction, we use bored or, but powerful, reinforced concrete piles of large cross-section and size are used more in the construction of industrial and civil facilities of large area and weight. And of course, there are also bridge rods - the most durable and powerful products among the entire range of pile production.

What are piles

In principle, all reinforced concrete rods that are currently on the construction market can be divided into:

- Factory made.

- Stuffed - such piles are arranged right on the construction site.

This is speaking on a global scale, but other than that, we can give examples:

- Screw piles. Metal rods that are screwed into the ground, and we can do this with our own hands.

- Bored. For this type, we need a well, and we can do the rest ourselves, install reinforcement and pour concrete.

- Buroinjection. Special equipment is already required here, both for drilling and for pouring concrete.

- Stuffed . These piles are rarely used specifically for low-rise construction, however, let's say that they are distinguished by increased strength.

Application of special equipment

Since we are most interested in a powerful structure today, we need a pile driver.

This special equipment is almost 200 years old, and it was invented in the era of the development of steam technology. Since then, of course, a lot has changed in technical terms, but the basic principles have remained unchanged, piles are still driven into the ground under the influence of a load.

Now in urban conditions, taking into account dense buildings, a pile driver, or pile driver, is not used on an industrial scale, but in construction far from a densely populated area, special equipment continues to drive in rods!

By the way, we have just answered the question, what is the name of the machine that drives piles, so the term pile driver can now be used everywhere.

Here it is necessary to clarify that a pile driver is a machine for installing and driving a rod, but the blows themselves are delivered by a hammer, or “woman”. However, if we just say a pile driver, this will be enough to determine the purpose of special equipment.

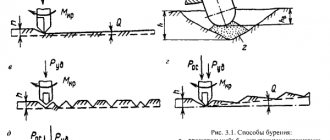

Be sure to say what types of hammer exist, as well as methods for installing and immersing the rod in the ground:

- Diesel hammer, runs on diesel fuel and uses impact force.

- The hydraulic hammer, works on the hydraulic drive.

In addition, there is also a pile-pressing installation, here the principle of operation is based on the method of transferring a static judgment to the rod.

Important! It is the static force that is most often used in urban work, when dense buildings do not allow for shock work.

In general, you can schematically display the work as follows:

- Installation for driving piles, pile driver, sets the rod in the design position.

- Next, the structure is pressed into the soil to the point of termination of natural immersion.

- The last step is driving the rod into the soil to the design depth.

It should be noted that there are alternative ways in which the device for driving piles, uses not only the impact force of the hammer.

This is, for example, vibration driving, when vibration is the main driving force for driving a pile.

In addition, modern construction uses some more methods:

- Driving, during which water washes away the soil and makes way for the rod.

- Vibration immersion, we have already mentioned it.

- Indentation. This method is completely silent.

- screwing . Screw rods are produced not only for low-rise construction.

- Preliminary well, this method can also be called a "punch".

However, we are talking about the industrial version, but can't there be a piling machine, for example, portable, manual?

No, the answer to this question is always negative, because according to the classification, this technique is divided into:

- Wheel technology.

- Caterpillar equipment.

That is, we are talking about vehicles, and not about a portable device. Another thing is that the device itself can be prefabricated, in other words, they brought it, assembled it and started driving piles, or it moves along with the car.

So, if we talk about industrial construction, large-scale, in which huge rods are used, with a cross section of up to 400 mm, then here we drive piles with a strictly pile driver, and one of the types of hammer.

Important! To be frank, the most common way remains a diesel or hydraulic hammer. Let it be noisy, but the pile is hammered to the desired depth “tightly”. At the same time, there is also squeezing of the soil, so that at the design depth there is a high-quality compaction of the cushion.

What can we

We can easily use all technologies and principles. Depending on the project, we have a choice of rods and their immersion.

The simplest instruction awaits us in the case of working with the screw version. Here the pile is short, at the level of 1.8 meters, and it can be screwed into the soil to a certain depth. The device and work will take literally one day.

You can use the bored method, drill wells and then fill them with a reinforcing element and concrete.

You can purchase ready-made reinforced concrete piles and rent a pile driver. This version of the foundation device will literally take a day. True, here we need to look at the cost, because the price of renting a pile driver, plus the cost of the material itself, can significantly hit your pocket.

Conclusion

The basic principles of pile driving have not changed since the first immersion of the rod into the ground. But the technical conditions have completely changed, and along with them the materials from which the rods are made.

Today we can take full advantage of all the new methods for installing piles on our site. And in the presented video in this article you will find additional information on this topic.

A builder who often encounters pile foundations and is familiar with the technology of their construction often does not know how the piles are buried in the ground and what kind of pile driving equipment is used in this process.

The most common way to deepen piles is to use a hydraulic or diesel hammer. Despite the fact that their use is quite noisy, there is a reliable deepening to the design depth.

At the same time, the soil is also squeezed, and the pillow is qualitatively compacted.

The use of piles is necessary if there are problematic soils on the site, namely:

- With a high location of the groundwater level;

- Significant soil heterogeneity;

- Marshy terrain, when working on which it is necessary to get to a dense bearing layer.

In the construction of low-rise buildings, screw or bored supports are mainly used, and powerful piles with a large section made of reinforced concrete are mainly used for the construction of civil and industrial facilities of considerable weight and area.

All piles available on the construction market are divided into two main types:

- Manufactured in factories;

- assembled directly at the construction site.

Types of piling installations

The complexity and time of its movement, as well as its installation and alignment, directly depend on the design of the pile driving machine.

In modern construction, the following types of pile drivers are used:

| |

| |

|

Application of special equipment

Installations for driving piles are used when it is necessary to deepen powerful supports. This technique was developed two centuries ago, during the period of intensive development and use of steam engines.

Modern units, of course, are not much like their predecessors, but the basic principles of operation have remained virtually unchanged.

In conditions of dense urban development, the pile driver (in other words, it is called a “koper”) is practically not used, but far from densely populated areas, there is still work for such equipment. The pile driver is directly the machine itself, with the help of which the installation and driving of piles is carried out, but the blows on the rod are applied by a special hammer, or “woman”.

Separately, it should be noted that there are several types of hammer, as well as methods for installing and deepening the pile into the ground:

- Diesel hammer, running on diesel fuel and using impact force during operation;

- Hydraulic unit operating on a hydraulic drive;

- Vibratory driver using an eccentric pendulum to drive the support into the ground;

- A pile-pressing installation that deepens a pile by creating a force of enormous magnitude.

In urban conditions, it is the pile-pressing machine that is most often used, when, due to too dense buildings, the use of percussion mechanisms is impossible.

The operation of a pile driving installation can be generally depicted in the following sequence:

- The pile is installed in the design position;

- Pressing the support structure into the ground until natural penetration stops;

- Driving piles into the ground to the depth required by the project.

It should be noted that in addition to driving, there are also other ways in which the machine uses not only the hammer blow. One of these methods is vibration immersion, in which vibration acts as the main force for deepening the pile.

In addition, in modern construction, methods such as:

- Hydraulic driving, in which water pressure is used to free the path of penetration for the pile;

- Indentation, characterized by noiselessness;

- screwing;

- “Punch”, a preliminary well for the pile is arranged with a special installation.

Vehicle types

Pile driving machines are divided into two types:

- Tracked;

- Wheeled.

Installations can be both prefabricated, mounted directly on the building site, and moving along with the machine.

Pile foundation is a fairly widespread foundation for any type of building. Pile driving can be done at any time of the year, in any weather and even in frozen ground. Depending on the type of foundation and the materials used, the technologies for deepening the support into the ground are also divided.

Piles for the foundation are divided into 3 types:

- bored,

- screw,

- driven.

Each type of support is deepened according to a certain technology. At the same time, driven piles are considered the most reliable foundation, therefore they are recommended for installation in the construction of heavy buildings.

Stilt houses are a very old building technology. Only the material of the supports and the machines that drive the piles change.

| Material | Constructive | Specificity |

| Reinforced concrete | They are made of concrete grade 300 and higher, reinforced inside. They come in various shapes: round, square, I-beam, have a pointed end. | Before the monolithic support is inspected for the absence of cracks, chips, damage. The top of the pile is protected with a steel head, which prevents damage to the monolith from hammer blows. |

| Wood | Made from solid wood. They have a pointed recessed end with a metal tip. The upper impact part is pulled together by a metal ring to prevent cracking during impacts. | To increase the strength of the foundation, "packages" are used - a bunch of several piles that are driven together. |

| Metal | Pipe with a tip and a cap. | Most often used in private construction. Steel is more technologically advanced than concrete and much more reliable than wood. Can be hammered into the ground with a hand hammer. |

Study of the device and workflow of the pile driving installation

1. Purpose:

1. To study the device of rod and tubular diesel hammers and the procedure for their operation.

2. Draw a diagram of a tubular diesel hammer.

3. To study the device of a self-propelled pile driver.

4. Learn how to select a diesel hammer.

2. Installation diagram:

For piling at urban construction sites, it widely uses energy-saving mobile diesel hammers. The diesel hammer is a direct-acting internal combustion engine operating on the principle of a two-stroke diesel engine.

According to the type of guides for the impact part, diesel hammers are divided into rod and tubular.

The shock part of rod diesel hammers (Figure 4.1) is a movable cylinder, open from below and moving in guide rods.

Figure 4.1. Tubular diesel hammer:

1 - pile head; 2 - shabot; 3 - fuel line; 4 - fuel pump;

5 – the lever of inclusion of the fuel pump; 6 - annular fuel tank;

7 - piston;. 8 - eye for attaching the piston to the winch rope;

9 - spherical head of the striker; 10 - suction - exhaust pipe;

11 - cylinder; 12 - pile

The tubular diesel hammer (Fig. 4.1) also uses the principle of an internal combustion engine, but it is structurally implemented differently. Stationary cylinder 11

, installed on the copra bar, is attached to the pile head through the chabot

2

.

Headpiece 1

and chabot

2

are in contact with spherical surfaces that compensate for the possible deviation of the hammer axis from the direction of impact.

Chabot 2

is a metal plug that closes the hole of the cylinder

11

from the side of the pile and is able to move relative to the cylinder in the axial direction when the piston

7

.

Its falling out of the cylinder is prevented by a locking device. Cylindrical gap between chabot 2

and cylinder

11

is sealed with compression rings.

The flat lower end of the chafer rests on the pile head 12

, and its upper end, located inside the cylinder

11

, has a spherical recess.

The piston 7

, which is the impact part of the hammer and freely moving along the cylinder

11

, ends at the bottom with a convex hemisphere, equidistant to the recess in the chabot

2

.

The operation of the tubular diesel hammer is carried out in the following sequence. Before starting the hammer, the piston 7

(Fig. 4.1) is lifted by the "cat" suspended on the rope of the copra winch to the highest position, after which the "cat" and the piston are automatically disengaged.

When moving down, the piston 7

turns on the fuel supply pump

4

, which, once in the cylinder

11

, is collected in the recess of the chabot

2

.

The spherical head of the striker 9

of the piston

7

, hitting the surface of the bowl

2

, sprays fuel in compressed and hot air, resulting in the formation and ignition of the air-fuel mixture.

The force of the explosion pushes the piston 7

up and the chabot

2

down, which is accompanied by pile driving.

Due to the impact on the pile of successively two impacts - mechanical and gas-dynamic - high efficiency of tubular diesel hammers is achieved. When the piston 7

upwards, the expanding gases, as the suction and exhaust pipes

10

, are released into the atmosphere.

Through the same nozzles 10,

fresh air is sucked in as the piston moves upwards.

Having reached the extreme upper position, the piston 7

begins to freely fall down, the working cycle is repeated, and in the future the hammer works automatically until the pile is completely immersed.

The jump height of the impact part of diesel hammers is regulated by changing the amount of fuel injected by the pump, which allows you to change the amount of impact energy depending on the type of piles and soil density. Tubular hammers are more efficient than rod hammers, since with an equal mass of the impact part they can drive heavier (2 ... 3 times) piles in the same period of time.

Tubular hammers also have increased durability compared to rod hammers.

Tubular diesel hammers develop an impact energy of 40 ... 60 kJ with a throw height of the shock part of 3000 mm and a compression ratio of 15. The number of blows per minute is 42.

The main indicator characterizing the immersing ability of the hammer is the energy of one blow. It depends on the weight and height of the fall of the shock part, as well as the energy of fuel combustion.

Impact energy (J) of diesel pile hammers

E=GHη

,

where G

– impact part weight, N;

η

– Hammer efficiency (for rod diesel hammers

η

= 0.35…0.40, for tubular hammers 0.60…0.65).

Required nominal impact energy

EN ≥ 25 R,

where R

- design load on the pile,

N.

According to the obtained value En

a hammer is selected (according to the relevant reference books), and then it is checked by the coefficient of applicability of the hammer

k,

which is determined from the ratio of the weight of the hammer and pile to the impact energy, i.e.

K = (Q1+q)/En,

where Q1

– own weight of the hammer, N;

q

- pile weight (including the weight of the cap and podkladka), N.

k value

ranges from 3.5 to 6 (depending on the material of the pile and the type of hammer).

For example, for driving reinforced concrete piles with a rod diesel hammer, k = 5,

wooden piles,

k

= 3.5, and tubular piles, respectively,

k =

6 and

k =

5.

Impact energy (J) vibratory hammer

,

where is the mass of the impact part of the hammer, kg;

– impact speed of the vibratory hammer, m/s (m/s);

R is the conditional coefficient of speed recovery upon impact.

Vibratory hammers and vibratory hammers work in combination with a pile driver or self-propelled jib crane of the appropriate lifting capacity.

Koprom is a metal structure intended for fixing a pile before driving, mounting a pile hammer on a pile, setting the direction of driving and extracting driven piles.

Copra are rail-mounted (universal metal tower type) and self-propelled based on cranes, tractors, vehicles and excavators.

The pile driver installation consists of a turntable or fixed platform on a chassis or supports, on which a counterweight, a cabin with controls, an engine compartment and a mast (koper) are located. The mast is pivotally attached to the platform by a support section, and its angle of inclination is fixed by hydraulic cylinders. In the upper part of the mast, a head and load blocks are mounted for installing a pile and a hammer, as well as raising and lowering them.

Conclusion: In the course of laboratory work, the device and operation of the diesel hammer were studied, the design of vibratory hammers, the device of a self-propelled pile driver were studied.

How piles are driven

Reinforced concrete piles must be driven below the freezing level

The main advantage of the pile foundation of the building is that, regardless of the soil temperature during its installation, the supports do not allow the structure to deform during operation under the influence of seasonal freezing and thawing of the soil. Such strength is due to the fact that the structural elements of the foundation are driven in strictly vertically below the level of soil freezing.

Pile driving occurs to the limit of reaching a dense layer of soil, if the soil is weak. Or by washing, if the soil is very dense. In this case, a hydrocopper and the necessary pile driver are used: water is supplied under pressure along the support, which softens the soil and reduces the friction force during deepening upon impact.

With an independent pile foundation, you should make sure that the support has the ability to go deeper in the direction of increasing load.

During construction, the load on the foundation will increase and the supports will lower.

If one of them rests against an obstacle (stone, rock), this will lead to a redistribution of the load and, as a result, the building will skew.

If the soil is frozen below the clogging level of the support, then work is carried out using a steam needle. A well is drilled, a needle is lowered into it, through which steam is supplied. After the soil thaws, the pile driver comes into operation and the support easily enters the ground.

Main types

First of all, you need to pay attention to the fact that there are several classifications of diesel hammers. It is worth considering two of them in more detail, since they are the most popular.

By type of construction

If we consider the classification according to design features, then diesel hammers are divided:

The features of these types should be considered separately, depending on the type chosen.

Rod

The design contains the following elements:

- a piston that stands on a special support;

- vertical guides;

- a system for supplying a combustible mixture;

- "cats" that ensure the fixation of the structure in the required place.

Upon closer examination of the details, you can see that the block is a monolithic structure.

It is cast inside the hammer body, and in the block itself, in addition to the piston, there are also compression rings, hoses through which fuel enters, and nozzles. The latter are responsible for spraying the mixture in the pump.

The block itself, as already noted, is on a hinged support. Its bottom wall holds vertical guides that ensure the movement of the hammer during the pile driving process. To make the structure more rigid, it was decided to connect the guides to each other with a horizontal traverse.

When the equipment is started, the hammer moves along the guides. It moves up and down to drive piles. Additionally, it should be noted the presence of a chamber for the combustion of the fuel liquid at the bottom of the body of the shock part.

Tubular

The design feature of tubular diesel hammers is that it is completely unified and created on the basis of a tractor. In other words, the production of such equipment is carried out according to a proven and well-established scheme.

Thus, such a hammer is practically no different from a standard tubular apparatus.

Basic structural elements.

- "Cats". They are the main equipment for fixing the hammer. The advantage of the device is the presence of an automatic mechanism that ensures the timely fixation of the element or its reset.

- Impact piston. Contains compression rings for improved performance.

- Saturday. This is the impact surface, in the process of hammer operation, in contact with the striker.

- Cylinder of the working part. In it, an explosion of the fuel mixture is carried out, which ensures the lifting of the hammer.

- Cooling system. Prevents equipment from overheating.

- Lubrication system. Provides durability to the structure.

- Guide tube. It is made from high strength steel.

Foundation equipment

For the device of the supporting foundation, a machine is used for transporting and feeding piles and driving piles.

Transportation and installation in a strictly vertical position are carried out using special equipment:

- lifting crane;

- pile driver.

You can install piles in a vertical position using both types of equipment. The difference is that the crane can be used in other areas of the construction site, and the pile driver is a highly specialized machine.

In modern construction, the following pile driving machines are used

| Type of equipment | Advantages | Flaws |

| diesel hammer | Do-it-yourself piling machine. Low cost of work, independence from other special equipment, saves time resources. | Very high noise level. |

| hydraulic hammer | Significantly reduced fuel consumption and sound levels. | Not independent construction equipment, but a nozzle on a pile driver. Cannot move on to another pile until the first one is driven. |

| vibrator | Nozzle, which is based on the ability to push the soil under the action of vibration. Allows you to significantly reduce the level of applied force and noise. | A very time consuming process. |

| Piling installation | The installation includes a small crane for supplying support, which makes it possible to save on a pile driver. The piles are fed into the central clamp, fixed vertically and pressed under the action of a huge force into the ground. | Assembly and dismantling of the installation. For the stability of the installation, plumb lines are used. The machine itself has a relatively small mass. |

From the name of the machine that drives or plunges piles, the method of deepening is directly related. 4 main ways:

- shock method;

- indentation;

- vibration. See an example of driving piles in this video:

- leader drilling.

If the foundation is the foundation of the building, then the pile is the foundation of the foundation. The quality of the entire construction depends on how high-quality material will be used and how carefully the technology will be observed.

If it is necessary to build a structure on problematic soil, the most rational option is a pile foundation. For example, on loose, moving or swampy soil.

Piles are widely used in both individual and industrial construction. And if during the construction of an individual one-story structure it is possible not to use special mechanisms, then the use of special devices and machines in industrial volumes is simply necessary.

We recommend buying construction and storage equipment only from reliable manufacturers. The company from St. Petersburg "KBmet" is engaged in the supply of all types of racks, including pallet and frontal. Don't delay, follow the link right now https://www.kbmet.ru/catalog/stellazhi-palletnie/.

Technical advantage of Baumatik installations

Double action hammer

Our most significant advantage over other piling rigs.

The initial load acceleration system accelerates the load 1.4-1.8 times faster, thereby achieving phenomenal impact energy compared to analogues.

Such systems are used only on professional copra. At the moment, there is not a single mini-piling rig in Russia that uses a similar system.

Siemens autodrilling control system

The IP65 protected Weintek operator touch panel is an interface that provides intuitive and multifunctional control of the unit. The heart of the system is the decades-proven Siemens control module.

The automatic control system for the force and frequency of hammer blows is one of the adjustable parameters of the system. Under the control of the system, all functions of the headframe, sight, as well as engine speed control and operator protection system.

Related article: Which foundation to choose

Vertical movement of the mast "Slider"

A node that allows the headframe mast to move up and down by 1000 mm, regardless of the position of the basket. Helps to "catch" the height of the pile when driving. Indispensable for removing the machine from the pile on difficult terrain.

It is used to change the center of gravity of the installation while moving on difficult terrain, thereby increasing the overall maneuverability.

Tracked chassis for special equipment

Classic crawler chassis for special equipment, rigid frame with factory-made track rollers. Steel, rubberized track.

The drive is carried out through a powerful gearbox from a high-torque gerotor hydraulic motor.

Hook pull (drive power) - 15,000 Newtons on board.

Hydraulic system

CASAPPA Polaris hydraulic pump with cast iron covers and high MTBF. Maximum alignment of the hydraulic pump and the engine through the "bell" and the elastic coupling. Triple filtration system "OMTF".

The cooling system is a hydraulic radiator "AKG" T-4 (T-5) with a forced fan. Main hydraulic distributors and piping of the “Parker” pile driver. The mains are made with hydraulic pipes with increased heat transfer.

Hydraulic locks on outriggers and load holding valves on mast, feed, winch and drive motors for safe operation.

Rigid housing frame

Power space frame is made of structural low-alloy steel 09G2S with increased resistance to negative temperatures.

All loads are modeled in the Dassault Systemes solid modeling environment, including numerical analysis of structures with the solution of strength problems.

The bearing elements are welded from sheets cut out on a laser cutting machine with tolerances up to 0.1 mm. For painting, we use only two-component polymer paint systems.

Outriggers and pile elevator

Outriggers with caprolon inserts eliminate the rocking and "hanging" of the installation. Auxiliary systems, such as an electronic sight and a vertical indicator, allow you to quickly set the machine to the working position.

The slider allows you to "catch" the height of the pile when driving. The towed cable chain (hose layer) protects the high pressure hose from breaking.

The pile elevator safely inserts a heavy pile (200, 300 and 400 mm) into the yoke.

Folding boom

Structurally reinforced collapsible tubular boom. Increased bending stiffness along the working axes.

Boom movement to the right and left by 5 cm - for precise positioning on the driving point.

The pile can be rotated around its axis in the hammer, providing the azimuth of the pile face relative to the pile field.

Optional winter package

The Webasto termotop kit preheats the engine cooling system. The oil tank is heated through the engine heating system using a coil.

After starting the engine and reaching an oil temperature of 30 degrees, the system turns off. This ensures a reliable start-up of the unit at negative temperatures and increases the overall resource of the hydraulic system.

Types of piles

Piles can be made directly at the construction site or in the factory. That is, when it comes to finished metal or reinforced concrete piles that are driven into the soil with special devices, the main task is to deliver the manufactured piles to the construction site. Self-manufacturing is considered to be drilling a well at the construction site and filling it with concrete mortar.

All piles are divided into the following categories:

- Driven piles. As a rule, reinforced concrete rods. In individual construction, they are rarely used due to the high cost of renting the necessary equipment and the piles themselves.

- Screw piles. Made from metal. Popular in the construction of low-rise structures. You can screw the rods both independently and using technology.

- Bored (buroinjection). First, a hole is made in the soil with a special drill, then it is filled with concrete mortar.

Classification of pile drivers

In accordance with the drive mechanism used, known pile driving units are divided into the following types:

- Purely mechanical devices.

- Steam-air (percussion) machines.

- Vibrating hammers.

In mechanical machines, the hammer is raised by means of a special cable, followed by its fall from a height of about 3 meters (photo below in the text).

Piling installation process

The operation is repeated until the pile sinks to the desired depth. The main disadvantage of this type of machine is the relatively low productivity.

Steam-air mechanisms are driven either by the power of steam, or they work from compressed air acting on the shock part. They are divided into simple and double cycle aggregates. In the first samples, the power of steam or compressed air is consumed only to lift the hammer, and in double-acting devices, it performs useful work when it hits the pile. Their efficiency is slightly higher than that of previous models. In the design of vibration-type machines, special elements have been introduced - imbalances that ensure the vibration of the actuator. Together with the shock impulse, the desired effect is achieved (if necessary, the pile can be removed from the ground). The disadvantage is that it can only be used for soft soils.

Be sure to read: Specifications ODAZ-9370

According to the method of moving across the working field, all machines of this class are divided into the following types:

- Wheeled.

- Caterpillar.

- Rail.

The choice of each of the pile driving units is determined by the conditions for carrying out the relevant work.

Machine working principle

The principle of operation of the pile driving machine is based on the well-known continuous auger technology, which involves pre-drilling a hole with subsequent pile driving. The main working operation is carried out by means of a massive cast iron casting (hammer) controlled by a drive mechanism.

In the simplest machines, when driving, it will rise along the mast guides to the desired height, and then (after disengaging the winch clutch) falls on the pile head under its own weight. The disengagement of the holding grip occurs with a strong tension in the drive rope of the control mechanism. The complete working cycle of the machine thus consists of lifting the impactor and then dropping it onto the pile head.

Pile driving equipment

Devices differ in the way of immersion:

1) Piling driver. The principle of operation of this device is to apply a series of blows to the pile. The blows are delivered with a hammer, which can be of the following varieties:

- Hydraulic hammer

. The lifting and lowering of the shock part is carried out by means of a hydraulic drive. Thanks to this, it is possible to regulate the force of impact. - Diesel hammer. Work is carried out due to the combustion of diesel fuel.

2) Piling installation. This device is capable of smoothly pressing reinforced concrete rods into the soil. Applying a series of blows to the rods in order to reach dense layers of soil by the rods is allowed only at the final stage of immersion. It is used near already built structures or residential buildings.

3) Vibrator. Creates vibrations along the pile axis. The device is powered by an electric motor or hydraulic drive.