Today, a tower crane is a completely unique equipment that allows you to perform almost any construction, installation, loading and unloading work.

This device is indispensable in the construction of tall buildings, in the construction of various ships, as well as in the transfer of oversized cargo. They are very often seen in large cities, in ports, at railway stations, as well as in large warehouses.

Modern tower cranes are distinguished by their performance and extensive functionality. They are actively exploited at construction sites outside the city, in settlements. Companies involved in the design of such special equipment regularly supply various models. And in order to choose the ideal technique, you need to take into account many factors.

Types of tower crane

- mobile models. Such equipment is used only on small construction sites. It stands out for its small carrying capacity, maneuverability, and acceptable dimensions. Giving preference to such cranes, you can save money.

- stationary models. They are distinguished by a fairly large carrying capacity. They are installed on a special platform, to which they are securely attached. Most often, such special equipment is used by firms engaged in the construction of high-rise buildings, overall buildings.

- Self-lifting models. They are distinguished by the fact that they can move significant structures to a sufficiently large height. They are often used if there is a need for the construction of complex, non-standard structures.

Installation, dismantling of a tower crane

In practice, a fairly large number of methods for mounting a tower crane are used. For each specific situation, a different method is used. The main factors influencing the choice of one or another method are: tower height and boom length, crane installation conditions, parking time.

In the case when the situation requires frequent transportation of the tower crane from one construction site to another, a crane of a special design is used, which allows the machine to be folded without dismantling it. The disadvantage of such a crane is that its installation requires a significant amount of space on the construction site.

For slewing cranes, the method of independently lifting the tower together with the boom using a chain hoist is used.

A universal method of mounting a tower crane involves the use of a stationary mast. Individual structures are mounted in parts in the desired sequence. In cases where the use of a mast is not possible, the installation is carried out using a light creeping crane.

Dismantling of tower cranes is carried out in the reverse order of installation.

Our group in Telegram. Join now!

Quick contact with the editors: read Excavator Ru and write to us on WhatsApp!

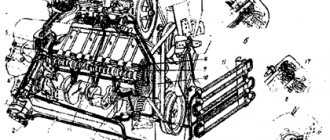

General design

The supporting part allows the crane to stand exactly in place. In addition, it is equipped with a tower, on which the slewing structure, boom and cab are mounted. In addition, this design can be supplemented with other devices, depending on the specific model. Most of the towers have a lattice look, but in addition to them, there are also telescopic ones. The crane boom is made of pipes woven together, so that it is possible to change its direction, height and length. The control cabin is usually located on the tower itself, and it also has the ability to change its height by remote or manual control.

As you know, tower cranes are currently divided into several main varieties. Basically, they are classified according to their purpose and functions.

Tower crane boom design

Arrows of tower cranes, depending on the method of changing the departure, are divided into lifting and beam.

Luffing jib cranes are the most widely used. This is explained by the fact that they have 15-20% less weight compared to cranes equipped with girder booms, are more technologically advanced in manufacturing, they are easier to mount and transport.

The disadvantages of cranes with lifting booms include: the lack of horizontal movement of the load when changing the departure; the need for increased drive power to lift the boom and load when changing the reach; relatively large minimum overhang. However, the value of the minimum overhang for mobile cranes does not play a significant role, since by combining two movements (rotation and movement of the crane), it is always possible to deliver the load to any point on the construction site. These shortcomings have been eliminated in new designs of cranes, as a result of which cranes with a lifting boom are successfully used both in loading and unloading and in installation work.

Promotional offers based on your interests:

Since the loads on the suspended lifting boom are applied along its axis, this boom, when lifting the load, works on central compression, while beam booms, in addition to compressive ones, also experience bending loads from the mass of the cargo trolley and cargo. The absence of bending loads makes the structure lighter. In addition, the small dimensions of the lifting boom in cross section compared to the dimensions of other booms facilitate the conditions for dismantling and transporting the crane from site to site.

According to the design, the arrows are divided into suspended (Fig. 22, a, e), suspended with a balancer (Fig. 22, b), suspended articulated (with a jib) (Fig. 22, c), suspended with racks (Fig. 22 , d) and hammer-shaped (Fig. 22, e, g). The most simple are suspended lifting booms, which have become widespread.

Rice. 22. Types of arrows: a - lifting suspended, b - lifting suspended with a balance beam, c - lifting suspended with a jib, d - lifting suspended with racks, e - lifting hammer-shaped, e - beam hanging, g - beam hammer-shaped; 1 - balancer, 2 - jib, 3 - rack

In terms of lifting booms have a different configuration (Fig. 23). According to the design of the belts and braces, the arrows are made lattice; from corners or pipes or solid-walled from pipes of large diameter, bent profile or sheet.

Lattice booms made of pipes have the most perfect design, which are lighter and stronger than angle booms. In addition, due to the good streamlining of pipes, wind loads on; tubular structures are much lower. All this allows to reduce the overturning moment acting on the crane, and thereby increase the stability of the crane. Now optimal designs of 4, 8 lattice lifting booms have been developed, providing their minimum weight and low manufacturing cost.

For cranes with an adjusting reach change, the support hinge for connecting the boom to the tower is made on plain bearings, for cranes with a shunting change in reach, more often on rolling bearings.

Rice. 23. Structural diagrams of booms: a - plan view, b - cross-sections of lifting booms, c - cross-section of beam booms; 1 - three-section, 2 - trapezoidal, 3 - A-shaped, 4 - optimal design, 5 - corner design, 6 - tetrahedral lattice of pipes, 7 - trihedral lattice of pipes; 8 - the same, optimal design, 9 - from a bent profile

The twin booms with struts used on the MSK-5-20 crane are similar to the suspended booms in terms of the nature of work and design.

Articulated booms (with jibs) are used, as a rule, when it is required to increase the reach and lifting height without altering the boom and changing the height of the tower (KB-160.4 crane).

Hammer-shaped lifting and beam booms work in bending, so they are much heavier than other types of booms. In addition, due to the significant dimensions in height, these arrows are difficult to transport.

A beam suspended boom (Fig. 24) has a KBk-250 crane. The arrow has a trihedral section. The cargo trolley moves along the two lower chords. The upper belt and braces are tubular. The lower belts (driving beams) are box-shaped from two welded corners. The boom has two working positions: horizontal and broken, when the supporting section of the boom is installed vertically and attached to the top of the head, and the head section is placed obliquely at an angle of 30° to the horizon. In this case, it is possible to significantly increase the lifting height of the crane. Thanks to a special scheme for reeving the cargo rope, horizontal movement of the cargo is ensured when the cargo trolley moves along the inclined boom.

Rice. 24. Beam suspended boom of the KBk-250 crane: 1 - support section, 2 - rack, 3 - head section

Additional selection criteria for a tower crane

- Be sure to decide whether you plan to purchase a new or used crane. When deciding, you need to remember that the period of active operation of such special vehicles does not exceed 18-20 years.

- When choosing a model, it is worth considering the time allotted for the implementation of a particular project. After all, the level of performance of equipment, its power may differ.

- As for the manufacturer, it is better to give preference to those companies whose service center is in the city. This will allow timely replacement of parts, carry out repair activities.

- It is advisable to buy only those tower cranes that have been thoroughly tested. This must be supported by relevant documents.

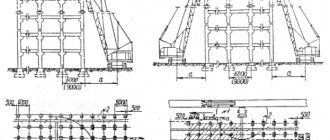

Tower crane running frame

An important element in the device of a tower crane is the running frame, which serves to transfer loads to the crane tracks. Fixed tower cranes have hipped or truncated pyramidal frames. For cranes with slewing towers, the loads on the frame are transmitted through a slewing device, which is located at the bottom of the machine.

Photo source: exkavator.ru The running frame serves to transfer loads to the crane tracks

Classification

There are several types of tower cranes.

By type of tower

Depending on the design features of the tower, these lifting machines can be:

- with swivel. It, with a fixed boom and counterweight, rotates around its axis in all directions;

- with fixed. The boom and counterweight are fixed on a special tent and rotate around the main support.

Arrow type

Depending on the type of this element, tower cranes are:

- with lifting boom. In the design of the crane there is a head, which makes it possible to change the angle of inclination;

- with beam arrow. It is motionless, equipped with a cargo trolley with a load gripping mechanism.

By installation method

Depending on the installation method at the facility, several tower crane schemes are distinguished:

- stationary (attached). It is installed in a certain place without the possibility of moving around the construction site;

- mobile. The machine can move by itself or with the help of a tractor along the crane runways.

Self-propelled models are most often equipped with a turret. This design of a tower crane is cheaper than others, facilitates its installation at a construction site and transportation. Stationary models are no less popular due to their excellent carrying capacity.

The device of a fixed-type tower crane allows you to increase its height by using special extension mechanisms. Such machines are installed at the beginning of construction and are rigidly fixed to the building. Gradually, as the work process progresses, the height of the special equipment is increased. Such models have a large reach of the boom part - about 30-60 m. This allows you to serve a significant area throughout the entire period of construction.

Classification by type of running gear

Depending on the chassis, this specialized technique can be:

- on a rail device. The most popular because of the ease of operation and installation;

- automobile. Mounted on the chassis of the car, which provides mobility to the technique;

- on the chassis of an automobile type. Are mounted on the chassis which is specially developed for this model, has a cabin;

- pneumatic wheels. The pneumatic wheel chassis is characterized by the absence of a cab;

- caterpillar. Such models are equipped with a caterpillar undercarriage;

- walking. They are equipped with a special running mechanism of a walking type.

Assembly steps

Assembly order:

- Installation of the turntable and running frame.

- Installation of a portal with a tower. Cabin installation.

- Crane lifting and boom assembly.

If you look at the video of how a construction crane is assembled, you can see that at the first stage, work is carried out using two truck cranes. This is a fairly compact and mobile equipment that can drive to any place on the construction site. One crane brings the trolley under the fastenings of the supports on the rail tracks, and the second one sets the turntable. Also, reinforced concrete blocks, which are counterweights, are mounted by a truck crane. If there are railway tracks in the immediate vicinity of the site, it may be more appropriate to use a railway crane.

The crane is installed according to a certain algorithm

The portal and the tower are also mounted using a truck crane. He also raises the driver's cab. The cabins are divided into two types - for working at a height of up to 20 m and high-rise, for working at a height above 20 m. The tower is assembled into several sections in height, after which a special “telescopic section” is installed, due to which the rest will be subsequently mounted.

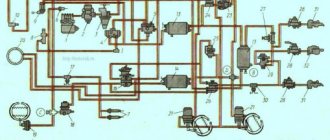

The connection and fastening of the farm nodes of the turntable and the portal is carried out manually, with hinged bolts, for fixing which a conventional sledgehammer is used. Also, manually connecting and setting up electrical equipment and fixing (reserving) steel ropes.

At the same time, the boom is being assembled. It consists of metal lattice sections. Assembly takes place on the ground, in a horizontal position. Install the boom with a truck crane. After that, at the final stage of work, you can see how the tower crane assembles itself. The boom picks up one section and pulls it up to the tower until it is inside the telescopic section. After fixing the hinged bolts, the "telescope" is raised to the height of the section and the cycle is repeated. Thus, the height of the tower is increased to the required one. The process ends with testing activities and the official acceptance of the equipment into operation.

Be sure to read: Liebherr truck cranes: photo, specifications, price

Operation Precautions

The weight of the crane can be more than 50 tons. Therefore, the processes of its assembly and transportation are strictly regulated.

During the installation and dismantling of a tower crane, it is prohibited:

- Be in the work area by unauthorized persons. To do this, the construction site is fenced and only workers directly involved in the process are allowed to access the crane parts.

- Raise and lower people with a crane. This prohibition entails another - to be on raised or lowered structures. No matter how good the view is provided by the operator's cabin, it is easy not to notice a person on the three-meter section being lifted. It is also forbidden to make any manipulations with the structures on weight. If something needs to be corrected, the load should be completely lowered to the ground and only handled after it has come to a complete stop.

- Be under lowered or raised structures.

- Leave lifted loads and metal structures suspended without supervision. This is especially dangerous in strong winds, but even in calm weather it increases the load on the crane and can lead to accidents.

- Drop objects from heights. The lowering of loads is carried out only with the help of a crane hook. Small items, garbage, etc. go down with the employees.

- Carry out work during thunderstorms, fog, ice and wind speeds of more than 12.4 m/s (6 points).

- Use cables, ropes and slings that have been spliced for any manipulation. If the rope has been broken, it is written off or used for other, less dangerous work.

- Carry out installation and dismantling work when the voltage in the mains drops by more than 10%.

When assembling the crane, safety precautions are required

During transportation, a number of requirements must also be observed. Tower crane elements are, as a rule, oversized cargo. Therefore, it is necessary to ensure that the dimensions of road trains do not exceed the maximum allowable values, taking into account bridges, overpasses and tunnels to be passed. The cargo must be rigidly fixed in the longitudinal and transverse directions and marked in accordance with the traffic rules. Transportation is carried out after obtaining a permit and accompanied by a traffic police car. During loading and unloading operations, it is necessary to use rope braces to prevent the movement and rotation of parts.

Be sure to read: Specifications of the DEK-251 crawler crane