Son dosibiral Minsk-Krokha, tried to start but did not work.

I looked with my eyes - the problem is in the spark. There is spark but it is very weak. threw in another candle and a coil - the same thing. I changed the capacitor to an automotive one - the same thing.

Catastrophically there is not enough time to study the principle of the magneto. can eat streams on this topic, who will tell you where to dig?

The magnet is new, the contacts also look almost new, clean, the gap is normal, there is no short in appearance in the anvil. Initially, he assembled as it was assembled before us, where the wire to the light from the horseshoe went to ground. During a cold run-in (I turned the crankshaft with a puncher for the magnet bolt), the magnet warmed up (I think because of such a connection)

Of course, it would be best to put an electronic one, but again, I don’t have time for this at the moment, and the child can’t cope on his own. Empty perishing at least us the usual train for a start.

Capacitor faults:

- open circuit

- breakdown

- poor contacts of the capacitor case with ground and the insulated conductor with the breaker terminal

These malfunctions are determined on the ignition tester (ICP) or using a test lamp. A test lamp connected in series with a capacitor and connected to a 220 V AC mains does not light when the capacitor is in good condition, but after the capacitor is disconnected from the mains, a spark appears during shunting. If there is a break in the capacitor, the lamp does not light, and the capacitor does not charge. When the capacitor breaks down, the lamp is on. The damaged capacitor is replaced.

Magneto - device and principle of operation

In 1887, German engineer and inventor Robert Bosch, owner of the company of the same name, developed and patented the first magneto-based ignition system.

It all started with the fact that one of the company's customers ordered the development of an ignition system for his gas engine, and soon the order was completed. Later, some shortcomings were revealed, and the device was finalized. As a result, by 1890, Robert Bosch GmbH was already fulfilling large orders for magneto ignition systems, which began to arrive from everywhere in huge quantities. Seven years later, in 1897, the device was eventually adapted to the vehicle, as it was necessary to develop an ignition for the De Dion Bouton tricycle. So the problem of ignition for automobile internal combustion engines operating at high speeds was finally solved. Five years later, in 1902, a student of Robert Bosch, Gottlob Hohnold, improved magneto ignition by adding a spark plug, and thus made the device universal.

So what is a magneto? How is it set up and how does it work? Everything is very simple, like everything ingenious. Magneto is an alternating current generator in which the role of an inductor is performed by a permanent magnet driven by an external force. The magnetic rotor creates a rotating alternating magnetic flux, which induces an EMF in the stator coil.

A typical automotive ignition magneto contains low and high voltage windings. The low voltage winding has an interrupter and a capacitor in its circuit, and the high voltage winding is connected with one of its terminals to ground, and with the spark plugs by its other terminal.

The common U-shaped yoke, on which the coils are wound, is a magnetic circuit in which an alternating magnetic field is excited by rotating a permanent magnet. Often, a part of the turns of the high voltage winding is used as a low voltage winding, similar to how the windings of autotransformers are made.

When the magnet rotates, an EMF is induced in the low voltage winding, but the winding is short-circuited by a mechanical breaker, so there is an induction current in it caused by the changing magnetic flux penetrating the core as the magnet crosses it with its lines of force. The change in magnetic flux lasts a few milliseconds, and as a result, there is a coil closed on itself with a current of several amperes.

At some point, the breaker contacts open, the current rushes from the winding to the capacitor, and harmonic oscillations begin in the resulting low voltage oscillatory circuit, their frequency is about 1 kHz. Since the contacts open quickly, in less than a quarter of the oscillation period of the primary circuit, there is no breakdown between the breaker contacts, and only after the breaker contacts open does the EMF in the low voltage circuit reach amplitude.

At this moment, a spark breakdown occurs on the candle connected to the high voltage winding, the energy of the capacitor of the low-voltage circuit is converted into AC energy of the high-voltage circuit, since oscillations in the low-voltage circuit continue, and the combustible mixture in the cylinder has time to ignite.

The oscillations last no more than 1 millisecond, due to the values of the inductance and capacitance of the magneto design, then the breaker contacts close again, and the next cycle of current growth begins in the low-voltage circuit shunted by itself.

Thus, we see that the magneto is a magnetoelectric machine, the function of which is to convert the mechanical energy of the rotation of the magnetic rotor into electrical energy, in particular, into the energy of a high-voltage discharge on a spark plug. Magneto-based ignition systems for internal combustion engines can still be found today.

Obviously, not every generator can be attributed to magneto, since only those generators that are excited by permanent magnets, and usually connected to a high-voltage transformer of the ignition system of internal combustion engines, belong to magneto.

It happens that the magneto provides not only ignition, but also the power supply of the vehicle's on-board network, but most often the magneto only feeds the ignition system. Meanwhile, today you can find on the market permanent magnet generators with several generator coils on the stator, such generators are suitable for motorcycles, but in principle they are universal.

In some cases, an additional winding located on the magneto core still serves to generate electricity for the on-board network. Sometimes the magnets are located on the flywheel, which has the dual function of excitation of the magneto and excitation of the alternator. Such a hybrid device is actually called "magdino" from a combination of the words "magneto" and "dynamo".

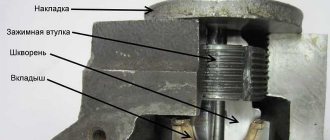

Breaker faults:

- burning or oxidation of contacts

- closure of an insulated contact to the housing

- cam runout

- changing the gap in the contacts

- broken contact spring

The oxidation of the contacts contributes to the failure of the capacitor. If necessary, the contacts are cleaned with fine glass sandpaper. Worn tungsten contacts are replaced with new ones. The normal gap between the contacts should be within 0.2 ... 0.25 mm. Defective amplifying contact springs are replaced with new ones.

Adjustment Features

Magneto adjustment is carried out if the node cannot perform the functions assigned to it, while all elements of the mechanism are intact. The magneto is tuned by measuring the gap between the contacts of the interrupter assembly, while the crankshaft of the motor should be turned by the flywheel. The shaft rotates until the divergence of the contacts is greatest. Let's adjust the gap by releasing the bolt that fixes the contact post and turning the hole post, which is installed in the slot of the eccentric.

When the gap is adjusted, it is necessary to test the mechanism - this will determine the correctness of the process. If everything is done correctly, then failures in sparking can be avoided.

Source

Magneto transformer faults:

- insulation damage

- short circuit and breakage of windings, leading to disruption of sparking

- nicks and rust on core bearing surfaces

Breaks in the windings are checked with a test lamp. In the absence of external damage, the magneto transformer is checked for uninterrupted sparking at the KI-968 stand.

Before testing the repaired magneto, check the correct assembly, the presence and tightening of fasteners, the smooth rotation of the rotor and sparking when rotated by hand.

In the assembled magneto, they check and adjust the angle of rotation of the rotor from the neutral position until the opening of the breaker contacts, the gap between the breaker contacts and the force transmitted by the spring to the breaker contacts. The magneto also checks the continuity of sparking, the state of high-voltage insulation, the correct alternation of sparks and the characteristics of the starting accelerator or ignition timing clutch.

Source and distributor of current - that's what you can call a magneto. Appropriate varieties of current are used inside carbureted engines so that the combustible mixture is ignited. In fact, thanks to this mechanism, mechanical energy is converted into electrical energy. A tractor magneto often comes with an internal combustion engine.

Magneto device, ignition advance clutchThe intensity of the magnetic flux that can be created by a rotor in a magneto magnetic circuit depends on the dimensions of the magneto, the residual magnetic induction and the coercive force of the alloy used to make the magnet.

Currently, magnets are made from nickel-aluminum alloys (NNA alloys), which have a high coercive force. The coercive force of magnets made of ZNA alloys is 8-10 times higher than that of magnets made of chromium steel, and 2-3 times higher than that of magnets made of cobalt steel.

Depending on the number of sparks created by a magneto in one revolution, there are two-, four- and one-spark magnetos.

On fig. 47 shows a two-spark magneto for a single-cylinder engine. On the magneto rotor 10 there is a strong permanent magnet 11. The rotor magnet 11 has pole pieces 12, which make it possible to obtain a minimum gap between the rotor and the core and protect the magnet from demagnetization. The pole pieces of the magnet, as well as the core with pole shoes, are made from electrical steel plates. The magneto core is placed in a housing 1 made of light alloy. On the core there is winding 2 with high voltage contact 3.

Cam clutch 9 is rigidly connected to the rotor axis; the ignition timing is changed manually with lever 6, with which you can turn the breaker disk along with the breaker itself. Capacitor 7 is placed inside the magneto case. High voltage is removed from the current collector contact 5.

Rice. 47. The device of a two-spark magneto: 1-case; 2 winding; 3 - contact; 4-lid; 5 - current-collecting contact; 6 - lever for adjusting the ignition timing; 7 - capacitor; 8 - breaker case; 9 - cam clutch; 10 - rotor; 11 - permanent magnet; 12 - pole pieces of the rotor; 13 - pole shoes of the core

In a magneto for a single-cylinder engine, the dog clutch has one lug, and in a magneto for a two-cylinder engine, two lugs. In this case, both pulses of the magnetic flux are used for sparking during one revolution of the rotor.

The high voltage current from the secondary winding of the two-spark magneto is fed through the contact ring of the distributor to the current-distributing segment, and from it through the sliding contacts and high voltage wires to the spark plugs.

Ignition advance clutch. A magneto with an ignition advance clutch is used on engines operating at variable speeds.

The ignition advance clutch consists of a leading clip 1 (Fig. 48), which is fixedly attached to the engine drive shaft, and a driven washer 7, rigidly connected to the magneto rotor. Weights 3 are placed in the cage on pins 5. Each weight consists of two parts connected pivotally on

axis 2. Springs 4 fix the weights in a certain position. Each spring is fixed on one of the components of the weight. The pins 6 of the driven washer enter the holes at the ends of the weights.

During engine operation, rotation from the drive shaft is transmitted to the magneto rotor through the cage, weights and clutch driven washer.

At low clutch speeds, the centrifugal force of the weights is small, and they are held by springs 4. The drive cage and the driven washer rotate at the same time without relative displacement and a change in the ignition timing.

With an increase in the number of engine revolutions, the centrifugal force of the weights increases and, overcoming the resistance of the springs 4, they turn on the axes and shift the driven washer by some angle relative to the cage in the direction of rotation.

Rice. 48. Ignition advance clutch: 1 - leading clip; 2 - axle weights; 3 - weights; 4 - springs; 5 - pins of the leading cage; 6 - driven washer pins; 7 - driven washer

The breaker dog clutch also shifts, increasing the ignition timing.

With a decrease in the engine speed, the centrifugal force of the weights decreases and, under the action of springs 4, they shift the driven washer to its original position, reducing the ignition timing.

Read about the electrical equipment of internal combustion engines ...

Read about all cars and vehicles

How magneto works

The device diagram will have the following description:

- Opposite the shoes of the magnetic cores are the pole pieces from the rotor.

- The transformer core contributes to the fact that the lines of force from the magnets begin to close.

- When the magnet is in a 90-degree position during rotation, the gap between the tips and shoes becomes the main element.

- Be sure to cross the lines of the magnet with the turns of the windings of the transformer. Due to this, the electromotive force acquires induction. Ignition is also used in processes.

EMF acts on the device in such a way that when using closed contacts, a magnetic flux appears at the transformer core. As a result of opening the circuit from its primary variety, the current disappears. Because of this, the magnetic field is sharply reduced.

EMF induction up to 25,000 volts occurs when using a secondary winding. Self-induction at EMF up to 300 V will appear only if the contacts from the primary winding are opened. The primary type circuit starts a self-inductive tone, due to which the magnetic current disappears more slowly. Such situations are characterized by a decrease in EMF for the secondary circuit.

Parts often begin to burn when sparks appear at the contacts. The connection of the capacitor to the structure is carried out in order to avoid such consequences. Then there is no spark between the contacts in the magneto, which is described above.

The rotor can be easily rotated to a 90 degree position. After the primary circuit is opened by a breaker. This moment is called the outline of the magneto.

Device diagram

The location of the transformer part inside the magneto on the tractor is characteristic. The part is pressed onto the shaft, which contributes to the creation of high voltage current. Another important part of the design is the rotor, which constantly performs the function of a permanent magnet with rotation on two bearings. The cam is fixed in front on the rotor shaft. On the back is the so-called leash. How each part works is easy to understand.

When the magneto device is mounted on the engine, the wire is supposed to enter the gear groove. The case is closed with a corresponding cover, which is used as a base for installing contacts from a breaker, leads at the transformer windings. The breaker itself is also closed with an easily removable cover.

Principle of operation

When the rotor rotates, an alternating magnetic flux , due to which an alternating electric current of low voltage occurs in the primary winding of the transformer.

The current in the primary winding creates an alternating magnetic flux crossing the secondary winding of the transformer. At the moment when the current strength in the primary winding reaches its maximum value, the cam opens the breaker contacts. The primary winding circuit breaks and the magnetic flux disappears.

a high voltage current is induced in the secondary winding of the transformer , which is supplied to the candle, resulting in a spark discharge between the electrodes . To reduce the burning of the breaker contacts, when opening, a capacitor is connected in parallel with the contacts.

Diagnostics of the technical condition

Diagnostics is carried out by performing the following procedure:

- The first stage is to bring the high-voltage cable to the output with voltage.

- At a distance of about 0.5-0.7 centimeters from the body of the device, the second end of the cable is constantly held.

- Maintaining the position of the wire. Next comes a sharp turn of the rotor in the direction of rotation. A spark should jump as a result of such a movement, if everything is in order, the magneto is adjusted correctly. If the spark is missing or too weak, it is likely that the installation requires a fault check. If necessary, adjustments are made.

Common faults and their repair

Here are just some of the problems that magneto owners may encounter most often:

- Failures in sparking. This situation has several reasons, ways to fix the problem. Possible problems include: contacts burn, oxidize; gap adjustment is violated; the lever cushion at the breaker has worn out; the capacitor element was broken. If the element is out of order, then it is completely replaced. When the problem is in the gaps, they are additionally adjusted. Contacts also change or are cleaned completely. How to set up a magneto is described further.

- Complete lack of spark. Often this happens due to the fact that the transformer wiring has broken, a short to ground has occurred, or the insulating layer that supplies the high-voltage cable has broken through. If there are problems with the transformer, the assembly must be replaced. You can eliminate the short itself or change the cable when there is a breakdown in the insulation.

- A broken capacitor is the most likely cause of a too weak spark. In this case, the part must also be replaced.

Magneto. Device and work. Types and application

Back in the 19th century, the German inventor Bosch, who owned his company, developed the first ignition system circuit based on the magneto. Over time, shortcomings were identified in the design and improvements were made to the device. As a result, the Bosch company in 1890 was already fulfilling large orders for the manufacture of ignition systems based on this principle. Orders came in in large numbers. In 1902, Bosch's student, Honnold, modernized this design and made it universal.

Magneto is a device that converts the rotational energy of the rotor into electric current, namely, into a high voltage discharge on spark plugs in a gasoline internal combustion engine. Currently, this device is practically not used, but it can still be seen on old car engine designs, or on tractor starting engines.

If we compare this device with a generator, the difference is that the excitation comes from permanent magnets. Depending on the device, a magneto can provide electricity to the vehicle's on-board network, and not just start the engine. But usually devices of this type are used only to ignite the fuel mixture, since their energy is not enough for other needs.

Device and work

This design is an alternator. In it, a permanent magnet acts as an inductor, which is driven by a motor. This magnetic rotor, during rotational motion, forms a variable magnetic flux, which induces an electromotive force in the stator coil.

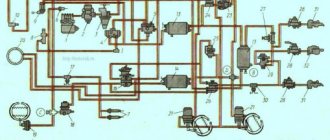

On a car, this device has two windings: high and low voltage. The low-voltage winding is connected to a capacitor and a contact breaker, and the high-voltage winding is connected at one end to ground and the other to the spark plugs.

The coils are located on a common U-shaped magnetic circuit, in which an alternating magnetic field is excited by the rotational movement of a permanent magnet. Usually, the low voltage winding is part of the high voltage winding, similar to the autotransformer device.

The operation of the magneto is as follows. When a permanent magnet rotates, an electromotive force is generated in the low-voltage winding. This winding is closed by the contacts of the interrupter, as a result of which an induction current appears in it, formed by an alternating magnetic flux in the magnetic circuit, since the permanent magnet crosses it with lines of force. The magnetic flux changes within a few fractions of a second, resulting in a large current flowing in a closed coil.

At a certain moment, the breaker opens its contacts, and the winding current rushes into the capacitor, resulting in low voltage harmonic oscillations. Since the contacts open at high speed, there is no breakdown between them. Only after they are opened does the electromotive force in the circuit reach its amplitude.

At this moment, a spark breakdown occurs on the spark plug, which is connected to the high-voltage winding, the energy of the capacitor is converted into high-voltage alternating current, because oscillations continue in the low-voltage circuit, and the fuel mixture in the engine has time to ignite.

The duration of oscillations is no more than one millisecond, which is determined by the capacitance and inductance of the device. Then the breaker closes its contacts again, and the whole cycle repeats.

As a result, we can say that the magneto is a magnetoelectric machine that converts the rotational motion of a permanent magnet into an electric current. Some versions of this device are equipped with an additional winding located on the magnetic circuit. This winding is used to generate electric current for the on-board network of a motorcycle or other vehicle. Permanent magnets located on the flywheel can perform two tasks - excitation of a high voltage for a spark on a spark plug, and excitation of an alternator. This combined device is called "magdino".

Varieties

Devices are divided according to several factors.

Direction of rotation:

- Left.

- Right.

By the number of sparks per revolution of the rotor:

- 1-spark.

- 2-spark.

By overall dimensions:

- Small-sized. They are used in motorcycles, mopeds, outboard motors, jet skis.

- Normal. Used in tractor four-cylinder engines.

Where is magneto used?

Most often, on outboard motors, motorcycles, mopeds, there are magdinos that function together with voltage regulators and rectifier bridges. Their power is small and can reach only 100 watts, but this is enough to operate the side lights or charge the battery. The advantage of Magdino is its light weight and small overall dimensions.

Magnetos have been commonly used in gasoline engines since ancient times, creating a spark in the spark plug, at a time when batteries were not yet so common. Currently, such structures are still found. During the war, carburetor engines were installed in German tanks, which used such an ignition system.

Aircraft piston engines have two spark plugs per cylinder. A separate group of candles works from a separate magneto - the right and left groups are connected separately. This allows the engine to work most efficiently, and also increases the reliability of the ignition system.

Communities › Motoblocks (and everything connected with them) › Blog › Replacing the magneto at the Krot cultivator

Good day!

Recently I wrote about the disappearance of a spark in the Krot cultivator.

There were suggestions for replacing the engine, why? The cultivator has been since 1991, has never let me down, has never broken down ... The replacement procedure is simple, all the tools are included

:

Communities › Motoblocks (and everything connected with them) › Blog › Replacing the magneto at the Krot cultivator

Good day!

Recently I wrote about the disappearance of a spark in the Krot cultivator.

There were suggestions for replacing the engine, why? The cultivator has been since 1991, has never let me down, has never broken down ... The replacement procedure is simple, all the tools are included

: