Manufacturers of mini-agricultural equipment offer a wide variety of devices that can greatly facilitate hard farm work, and among such devices it is worth highlighting a walk-behind mower. Most of the agricultural mini-equipment is expensive and not every private trader can afford to buy such equipment. It is for this reason that many folk craftsmen create such devices on their own.

Homemade rotary mower for walk-behind tractor

Types of mowers

To make a normally functioning homemade mower, home craftsmen, as a rule, use all available tools at hand. Do-it-yourself equipment for a walk-behind tractor allows you to save a lot and at the same time get moral satisfaction from what you have done. Making a mower on your own, in principle, will not be difficult, since you can find quite detailed descriptions with drawings and video instructions on this topic on the Internet.

As a rule, a do-it-yourself mower for a walk-behind tractor is front-type equipment, and which has the following types of construction:

- rotary;

- segment;

- platform mower.

Rotary mower Segment mower Platform mower

Most often, home-made mowers are created on the basis of ready-made models of factory-made attachments. Drawings of such structures can be easily found on the Internet, as well as viewed on numerous videos.

The basis for the equipment is a chassis made of steel angle 40x40 mm or any available. Bearings for the wheel axle are installed on the chassis, and after that the main equipment assembly is mounted directly.

Principle of operation

First of all, it is worth noting that this kind of mechanism is intended for work that is performed in meadows and fields, namely, mowing. Moreover, it can be not only crops that are grown in the agricultural area, but also the device is quite easily and simply able to cope with weeds, which actually also overwhelm our fields.

With the help of detailed instructions for the repair of Husqvarna 137, you can easily eliminate malfunctions in the operation of the saw.

There are a huge number of chainsaw attachments, here //machinspec.com/lesozagotovitelnaya/benzopila/nasadki.html you will find the one that is right for your work.

On this site you will find an introductory video about the Stihl 180 chainsaw, which will tell you about the correct operation of the tool.

It is this kind of activity that is the main focus of the functionality of rotary mowers, which are a kind of trailers to the tractor that moves them.

It is worth noting that this mower has three types of peculiar connection to transport, namely: mounted, trailed and semi-mounted.

Moreover, this cutting device has the possibility of a kind of separation, which lies in the fact that the tool can be installed both from the side of the mower, in front , as well as in the rear area of \u200b\u200bthe device.

As for the very launch of the operation of a mower of this kind of direction, it can actually be carried out both from the transmission of the tractor itself, and by moving the wheels of this vehicle. On a frame made of metal, a support wheel is attached, it is it that has the cutting element.

By actually producing its movement, it, let's say, provokes a cutting system to move, it is thanks to this kind of process that the mowing itself is performed.

Moreover, this kind of mower can have the presence of three peculiar knives. In fact, their number directly depends on the model of the device itself.

It is worth noting that such a number of these elements is the most optimal and efficient, as the level of performance of the tool itself increases . And in general, rotary mowers have quite significant indicators regarding safety and quality.

Rotary mower

This equipment can be used for cutting lawns, as well as for cutting fresh grass cover for hay. However, it should be taken into account that such a mower cuts high vegetation, and simply crushes low grass. You can see the equipment in action in this video.

The main working elements of the device are knives, which are installed on the working disks by means of a shank. The mower is driven by a power take-off shaft, and sliding is carried out by rotating the lower discs.

To make the frame of a rotary mower with your own hands, you can use old metal corners or scrap metal, which every craftsman probably has on the farm. In order to save time for knives, you can use the tractor rotor. However, in this case, in order to improve traction and efficiency, it is desirable to reduce the length of the rotor from two to four centimeters, depending on the power of the unit used.

To make a rotor, you need to make 2 round plates with a diameter of 390 mm from a sheet of metal, or use the bottom from an unnecessary tin barrel for machine oil for this purpose. Exactly in the middle of these circles, weld the legs with which rotation will occur. The welded connection must be made strong.

Do-it-yourself rotary mower

For the lower support, you can take a disk from a cultivator, but its diameter should not be more than 450 mm. For the axial shaft, a pipe with a diameter not exceeding 30 mm can be used, and bearings No. 180, 106 will still be needed. Make a hole on it for mounting the lower bearing, and the second bearing is mounted on the pulley. Put a fixture with knives on the axle, and then attach the pulley to the shaft by welding. The rotation of the working disks will be carried out using two bearings.

This modification has a grip of 1100-1150 mm and a rotation speed of 1500 rpm. The entire design of the mower must be mounted on a chassis welded from a steel angle. For safe operation, it is imperative to install a protective cover on a home-made device. To simplify the design, the lower discs of the rotary mower can be fixed to the frame by welding.

This homemade mower is able to cut vegetation at a speed of 8-12 km / h. At a high speed, the grass is more chopped, and at a low speed, the grass is more complete. Such rotary-type equipment can cut vegetation of 60-80mm and is used not only for mowing grass, but also for cleaning a personal plot from weeds.

Tools and materials

- welding machine;

- fasteners;

- metal corner;

- the bottom of an old metal barrel;

- eight cutting plates;

- wheel axle;

- two wheels.

Using a chainsaw

A petrol mower will be an excellent help in the economy. But first you need to prepare tools and spare parts. Domestic models "Friendship" and "Ural" are suitable for solving the problem. Additionally, you will need to purchase:

- metal corner;

- 2 wheels;

- pipe cut;

- metal knives;

- metal plate;

- rotor disks;

- bearing;

- accessories.

As for the corner, it will go to the manufacture of a rigid frame. But a metal plate will be needed for the site. You can not buy wheels, but borrow them from a stroller or cart. The pipe cut must have a diameter within 5 cm. To mate with the pipe, you will need a gear. A homemade mower will be made using fittings, namely:

- nuts;

- bolts;

- rivets;

- staples.

Segment mower

In order to make a fully functional and working segment mower with your own hands, you should take a metal pipe with a rectangular section of 1200x50x15 mm or a piece of a regular braid web, and drill twelve 10 mm sockets at an equal distance for installing M8 mounting bolts. Subsequently, a guide metal strip 890 mm long with teeth and knives installed on both planes of a rectangular pipe will be attached to them.

Homemade segment mower

Knives have backs with segments and holders of the drive lever. Clamps and skids are also installed on the pipe on both sides. A support wheel is mounted on the mower chassis. The working part of the segmented mower is driven by the power take-off shaft of the power unit used.

Segment mower drawing

Thanks to the use of a segment mower, it is possible to carry out high-quality beveling of fresh vegetation without shredding it. On the video you can see the operation of the equipment.

https://www.youtube.com/watch?v=kNfjFzqZutI&feature=youtu.be

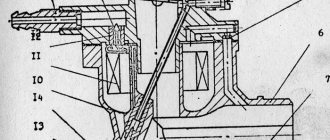

Device

The KSF-2.1 mower consists of the following main structural elements and parts:

- The frame on which the rest of the working tools are based and has a mount for attaching to the tractor hitch.

- The pull rod is designed to connect the working cutting tool with the frame of the device.

- Cutting the blade with sharp segments (fingers).

During operation of the mower, the blade with knives is driven by a reciprocating motion parallel to the ground. In this case, the stems that come across on the way fall onto the fixed segments of the web and immediately press tightly against them, moving the blades. Grass cutting is similar to the work of ordinary scissors, leaving a strip of finished mowing. Scheme of the KSF-2.1 mower 1. Cutter head; 2. Knife guide heads; 3. Knife head cover; 4. Home shoes; 5. Crane rod; 6. Street shoes; 7. Field board; 8. Finger; 9. Finger insert; 10. Piece of knife; 11. Clip knife; 12. Knife back; 13. Friction plate.

Platform mower

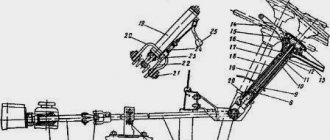

Drawing mower-wagon

This drawing shows a variant of a platform mower that is effectively used in summer for mowing grass and weeds, and in winter as a snow plow. For cleaning snow masses, special nozzles in the form of stars are mounted on the equipment, and in summer - knives. This modification is similar to a rotary mower, however, it is difficult to perform. This equipment allows you to cut hard grass and remove snow drifts with ice.

The design of this do-it-yourself equipment consists of two cylinders connected by hooks to a frame and a conveyor belt. The chassis is created from a corner or any other metal that can be found in the workshop. Wheels are installed on the chassis, which can be taken from an unnecessary stroller, and a thick plywood sheet, although ideally it is better to use metal. Frame dimensions can be different, but 800x400 mm will be optimal.

The main assembly consists of two cylinders (5), a belt (3), a frame (10, 16, 17, 18,20), brackets (19), hook corners (4).

Working cylinders can be made from large tin cans, in which it is necessary to cut out the bottom and lid, and install two wooden rounds in their place. Instead of cans, you can use a thin metal sheet and make 4 discs with an outer diameter of 200 mm and 4 with an inner diameter of 170 mm from it. Using bolts, connect in pairs small disks with large ones. Attach four knives to these disk structures.

Frame assembled by hand. The equipment consists of an upper crossbar (10) and a metal strip with corners and heel bushings (16). For the crossbar, you can take a metal corner 35x35 mm. The cylinders are interconnected by a belt, for installation of which grooves 13 mm wide are drilled in the corners. For the same purpose, the lower bushing of the driving drum is movably mounted on the bar (15), and tension angles (20) are installed on the upper axes of the cylinders. To the ends of the transverse beam, the tensioning of the corners (20) is carried out using M5x65 mm screws. It is easier to make a belt for drums from a rubber strip, the ends of which are connected using a 2 mm thick dural plate.

Next, connect the mower to the power take-off shaft of the walk-behind tractor. The work of the mower-cart can be seen in the presented video.

A few words about the scope

Hay harvesting, like any other job, has certain requirements. They include:

- Speed. Hay harvesting should be done as quickly as possible. In the process of flowering, the grass accumulates the maximum amount of nutrients. Therefore, you need to have time to collect it at this very moment.

- Quality. The grass should be cut as low as possible. The better the work of the scythe, the more hay will be harvested.

- Accuracy. When making hay, the scythe should not touch the ground. The presence of dirt and turf in the cut grass is unacceptable.