Back in the good old 60s, they began to produce 8-cylinder V-th engines at the Yaroslavl plant, which are known from the YaMZ 238 series. The design of these engines is quite simple, so the engines are reliable and last a long time without any problems. They work on diesel fuel, they were installed in trucks such as MAZ, KamAZ, KrAZ and Ural. By the way, towing a truck is not such an easy process, so it’s better not to break it down while driving. Today we will talk about such an important point as adjusting the YaMZ 238 valves.

Why you need to adjust the valve mechanism and preparation for adjustment

Since the parts of the YaMZ 238 engine heat up during operation, they are subject to elastic expansion. Therefore, periodic adjustment of the valves is necessary so that the valves fit as tightly as possible to the seat when heated. In addition, we must remember that during the operation of the motor, the following features appear:

- the thermal gap, which has increased in size, will worsen the operation of the combustion chamber, and the timing parts will also wear out faster;

- if the gap is too small, there will be no tight connection between the cylinder head seat and the valve, this will lead to a deterioration in engine performance, and the risk of valve burnout will also increase.

First you need to turn off the fuel supply, you can turn off the injection pump by turning the backstage bracket down, it is installed in the speed controller housing.

Preparation for valve adjustment:

- let the motor cool down to 30 degrees;

- remove the valve cover;

- check how well the timing rocker axles are tightened, initially this force is in the range of 120-150 Nm.

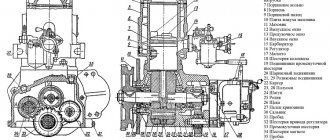

Gas distribution mechanism

A separate mechanism is provided for supplying air mass to the combustion chamber and exhaust gases. It is driven by a crankshaft. The mechanism consists of:

- camshaft;

- Drive gears;

- rocker;

- pushers;

- valve mechanism.

The transmission of torque to the camshaft of the mechanism is carried out through gears. When the crankshaft moves, the intake and exhaust valves open alternately. The opening of the valve mechanism is carried out in a certain order.

ATTENTION: The speed of rotation of the shaft, the gas distribution mechanism, depends on the speed at which the engine crankshaft rotates.

It is necessary to check the actual values \u200b\u200bof "thermal compensators"

According to the manufacturer of this motor, valve adjustment is necessary if the values of thermal compensators have gone beyond 0.25-0.30 mm. To accurately measure the gaps of 2 valves of each cylinder, you must wait until the compression stroke comes, and then you need to:

- focus on the first cylinder;

- clockwise (if you look at the radiator from the front of the car) turn the crankshaft;

- also clockwise from the same side, until the intake valve closes (until the suction stroke is completed), that is, the end that contacts the rocker toe should rise to the highest point;

- continue turning the crankshaft another 1/3 turn or 120 degrees in the same direction.

You can determine the cylinder number like this:

- look at the fan from the front of the car;

- the closest cylinder to the left is the first one;

- the nearest cylinder on the right is the fifth;

- the leftmost is the 4th cylinder, and the rightmost is the 8th.

It will also be interesting: Replacing the timing belt: a vital process during car maintenance

You can rotate the crankshaft like this:

- in front, scroll the crankshaft with a ring wrench for fastening the pulley;

- turn behind the flywheel with a special crank.

The size of the gap can be determined by the thickness of the probe, which is placed between the end of the valve and the tide of the rocker. The valve cannot be corrected if the probe with a thickness of 0.25 enters freely, and already the probe with a thickness of 0.30 enters with an interference fit. Approximately all the same must be done during the tuning of the Moskvich, if it requires valve adjustment.

Before adjusting the valves on the YaMZ 238 motor, it is necessary to press the rocker arms:

- cylinders 1-4, which are on the right side, press their exhaust elements against the end of the axle, and the inlet parts - against the thrust washer;

- with cylinders 5-8, which are located on the left side of the block head, on the contrary, press it.

Adjustment of valves

Turn the crankshaft clockwise until the valves of the first cylinder close. . From this moment, we turn the shaft another 90 °, and at the same time make sure that the valves remain closed. . We adjust the gaps in both valves - they should be in the range of 0.25-0.30 mm. You can check this with the appropriate probes.

Zhukov's list begins, as you might expect, with a tank that is considered the backbone of the Russian army's lethal force, the T-90 main battle tank. The tank has many versions and modifications adapted to specific combat conditions. The T-90s, built in central Russia at the Nizhny Tagil Machine Building Plant, get their engines from the Chelyabinsk Tractor Plant, located about 350 kilometers south of Nizhny Tagil. Export versions of the tank, designed to work in high temperature areas, are equipped with improved engine cooling systems.

YaMZ 238 valve adjustment

If the gap size is incorrect, then you need to do the following:

- loosen the nut on the adjusting screw, it is located at the other end of the rocker arm;

- then it is necessary to insert a probe with the required thickness between the end of the “shut-off element” in the combustion chamber and the lever;

- then it is necessary to turn the screw with a screwdriver until the required value of the thermal compensator appears;

- so that the screw does not spin further, it is necessary to tighten the nut;

- check the gap again and if it does not fit, then you will need to do the steps above again.

Next, adjust the valve mechanism in the order 5-4-2-6-3-7-8, in the position when the cylinder inlet is closed + 120 degrees clockwise. In the end, you need to re-check the clearances on each valve. Here, fluctuations within 0.20-0.35 mm are already allowed, due to the inaccuracies of the timing parts.

At the very end you need:

- start the engine and listen for knocks;

- see what condition the gaskets are in and, if necessary, change them;

- install the cylinder head covers in their place.

If characteristic ringing knocks are heard while the engine is running, this means that you will have to double-check each valve and other timing units again.

A quick way to adjust the valves on the YaMZ-238 engine

Hello my digital friend!

Due to the fact that we are sorting out the YaMZ 238DE2 engine with our own hands, we are faced with operations to adjust the thermal clearances of the engine valves.

The main difference between the adjustment methods is not in unscrewing the adjusting nut and tightening the rocker arm adjusting screw, and not in the subsequent setting of the gap between the valve and the rocker arm, that is, there are no differences in the procedure for adjusting the valve itself. The differences in the methods for adjusting or checking the thermal clearance of the YaMZ engine valves are to set the TDC of the compression stroke of 1 cylinder and the further procedure for sequentially bringing the cylinder pistons to the TDC, and each method or sequence of adjustment actions has its supporters and opponents.

It is necessary to check or adjust the gaps on a cold engine or only an hour after it has stopped. The gaps must be adjusted by 0.25 - 0.3 mm (tolerance 0.2 - 0.4 mm). For the valve adjustment procedure, you need a set of feeler gauges for adjusting clearances, a 19 wrench and a wide screwdriver. It is very convenient to use 2 spark plug keys from a gas tool to adjust the valves.

When we adjusted the thermal clearances of the valves on the YaMZ-238DE2 engine, for the first time we tried the method of bringing the pistons to TDC after the inlet (left) valve was activated when 2 valves were closed. According to this method, it is possible to adjust the valves first from the 1st side of the engine, then from the 2nd side, successively adjusting the piston of the next cylinder to TDC, after the left intake valve is activated. This method, in my opinion, is very laborious, although it allows you to accurately set the thermal gaps.

Let's summarize

We shut off the fuel supply, remove the valve cover, check the tightness of the timing rocker axles. Then the intake and exhaust valves of the motor are adjusted in the following range: 0.25 - 0.3 mm. and this should be the procedure for adjusting the YaMZ 238 valves:

- it is necessary to rotate the crankshaft by the flywheel or by the pulley, set the valves of each cylinder on the compression stroke;

- to check the gap, insert a feeler gauge between the end of the valve and the lever that swings;

- loosen the adjusting screw nut;

- then put the probe;

- it is necessary to turn the screw, which will achieve the required indicator of thermal compensation;

- tighten the nut;

- again, using a feeler gauge, check the size of the gaps, and if necessary, repeat the procedure;

- continue setup in this order: 5-4-2-6-3-7-8;

- rotate the crankshaft and re-check the size of the gaps, it can be in the range of 0.20 - 0.35 mm .;

- turn on the motor and listen for knocks;

- put the cylinder head cover back in place.

It will also be interesting: Pros and cons of leasing a car

And then a video about adjusting the YaMZ 238 valves:

YaMZ-238 engine adjustment

Check and adjust the thermal clearances of the valve mechanism before and after the break-in, but not earlier than 15 minutes after stopping the YaMZ-238 D, DE, AK, M2, B, ND engine.

Before adjusting the valve clearances, turn on the fuel supply with the regulator bracket, remove the cylinder head covers, check the tightening of the rocker axle nuts with a torque wrench with Mkr 118–147 Nm (from 12 to 15 kg/cm).

Technical requirements for tightening according to OST 37.001.031-72.

When adjusting the valve clearances and re-checking them, press the rocker arms:

- on the head of the right row of cylinders: exhaust valves - to the end of the axle; inlet valves - to the retaining ring.

- on the head of the left row of cylinders: exhaust valves - to the retaining ring; intake valves - to the end of the axle.

The exhaust valves of the right bank of cylinders are located closer to the fan, the left bank of cylinders is vice versa.

To adjust the gap, loosen the locknut of the adjusting screw, insert the feeler into the gap and, turning the screw with a screwdriver, set the gap within 0.25-0.30 mm.

While holding the screw with a screwdriver, tighten the locknut and check the clearance. A probe 0.25 mm thick should enter freely, and 0.3 mm thick - with force.

When cranking the crankshaft after adjusting the valves, due to the possible beating of the mating parts of the gas distribution mechanism, a thermal gap of 0.2-0.4 mm is allowed.

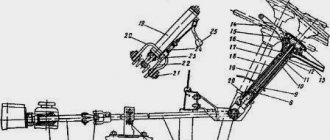

Adjustment of clearances in the valve mechanism is determined by the order of operation of the cylinders 1-5-4-2-6-3-7-8 and is carried out in the following sequence:

Rotating the crankshaft clockwise (from the fan side) with a special key for the pulley hub bolt and observing the movement of the inlet valve of the first cylinder, set the moment when it fully rises (i.e., completely closes), then turn the shaft another 1 /3 turns.

At this time, the compression stroke occurs in the first cylinder and both valves of this cylinder are closed.

To adjust the valve clearances of the next cylinder, turn the crankshaft in the direction of rotation until the valves of the regulated cylinder are completely closed and turn an additional 1/3 turn.

Adjust the clearances in each cylinder as described above.

Adjustment of the fuel equipment on the engine YaMZ-238 D, DE, AK, M2, B, ND:

— Check and, if necessary, adjust the fuel injection advance angle.

- Warm up the engine to normal thermal conditions.

Fig. 14 - Scheme of the speed controller

1 - power adjustment screw; 2 - body of the buffer spring; 3 - cap nut 4 - bolt limiting the maximum speed 5 - bolt limiting the minimum speed

Unscrew the cap nut and the power adjustment screw with the regulator control lever resting against the maximum speed limiting bolt, set the power at a crankshaft speed of 1900 50 min-1, which should be (under standard conditions according to GOST 18509-88) at hourly fuel consumption not over 66 kg/h;

After adjusting the power, screw the cap nut onto the power adjustment screw until it stops.

In the control chart for the YaMZ-238DE2, 238B, 238DE engine, the actual value of atmospheric conditions, temperature and fuel density should be recorded.

The hourly fuel consumption is determined by weight by measuring the time of consumption of 500 grams of diesel fuel twice, and the results are determined as the arithmetic mean of two measurements, which should not differ from one another by more than 2%.

To maintain a constant fuel temperature at the time of measuring the flow, the level in the tank should not fall below 2/3 of the height of the tank.

Around the drain pipelines immersed in the measuring tank, a slight release of small bubbles is allowed.

Adjust the minimum idle speed. Adjustment should be made with a bolt, on the stop, in which the regulator control lever should be located.

When the bolt is screwed in, the speed increases, when it is screwed out, it decreases.

Set the crankshaft speed within 640-660 min-1, then screw in the buffer spring housing until the speed is stable.

The idle speed should be within 650-750 min-1.