Characteristic features of snow and swamp vehicles

ATV engine

The main feature of all-terrain vehicles on low-pressure tires is the presence of a frame on articulated joints. Thanks to it, the wheels are able to fit at any angle, which is necessary to increase cross-country ability.

This design prevents the all-terrain vehicle from falling over on its side. This is especially important when driving on rocky, crumbling surfaces.

The number of bridges for this technique can vary from two to three. The motor of the all-terrain vehicle is diesel or carburetor. The latter is considered more efficient for long trips, such as hunting.

How to make an all-terrain vehicle from a walk-behind tractor?

An all-terrain vehicle with an engine from a walk-behind tractor is manufactured following a specific pattern:

- The base of the device is created. Most of all, ready-made frames are like. You can take them from the old equipment Ural and Izh. Such frames are distinguished by strength and maneuverability;

- Rear axle. Includes rear and front suspension, which are assembled from a rack, swath and steering sleeve;

- Wheel base of the unit. You can use an old truck spare. The walk-behind tractor on low-pressure chambers is easy to operate and quite maneuverable;

- A prefabricated motor structure is installed to perform its functions by the all-terrain vehicle;

- Once the motor system assembly is completed, the transmission, exhaust elements and brakes are installed. The latter can be taken from an old car or motorcycle.

Varieties of all-terrain vehicles with low pressure tires

Universal designs of snow and swamp vehicles on low-pressure tires are called all-terrain vehicles. For all-terrain vehicles there are no barriers. Due to the special structure of tires, such machines are able to overcome even shallow streams and rivers. But the technique can also be directed to travel on certain types of soil. Depending on this, the models are divided into:

Snow and swamp vehicle on ultra-low pressure wheels

- snowmobiles;

- swamps;

- amphibians.

The first of them is more often used in the regions of the Far North, where the tundra is covered with snow for almost a year. They are needed not only for vacation trips or hunting. For residents of remote villages, this is the only way to get to civilization.

The second type is designed for trips in swampy areas. Swamps are used for hunting ducks, elks, wild boars. As for amphibians, they are able to move through the water due to the presence of special floating fillers inside the wheel disks. Another important feature of amphibians is the tightness of the bottom and adjacent compartments. A water-jet device is sometimes used to move through the water.

Varieties

There are not only wheeled all-terrain vehicles, but also tracked ones. The latter option is used for complete off-road, when moving on eroded clay soil. A separate group can be identified sealed snow and swamp vehicles that can overcome any water obstacles.

By type of control, all-terrain vehicles can be:

- with automatic transmission;

- with manual control.

There are also types of machines according to the field of application. There are 4 classes of all-terrain vehicles:

- passenger (for tourists, hunters and fishermen);

- freight (transportation of equipment and materials);

- cargo-passenger (used by forwarding and geological teams);

- industrial use (special equipment equipped with additional equipment).

There is also a classification for tires with low pressure. There are 4 types:

- Toroid. Versatile and durable, the profile is close to the wheel diameter.

- Arched. Tire pressure level does not exceed 0.05 MPa. The width can exceed 5 times the standard tire. Are established on the leading bridge, overcome any impassability.

- Pneumatic rollers. Differ in the big sizes, the surface is equipped with cargo hooks. They have a strong cord, in terms of elasticity they are ahead of arched models. Not used for heavy loads.

- Wide profile. Designed for special equipment, heavy loads.

There are also tube and tubeless tires. The second type does not deform under loads. On the end sides of the wheels have an additional seal, the inner layer has a thickness of 2 mm, which ensures high sealing. These tires have a low degree of comfort.

Chamber options have less weight, but are subject to mechanical damage, can be deformed under load.

In addition to factory models of cars, there are home-made all-terrain vehicles, often not inferior in their technical characteristics.

Pros and cons of low pressure tires

All-terrain vehicles are usually equipped with special wheels, although there are models with caterpillar suspension. On all-terrain vehicles on low-pressure wheels, tires, due to their structure, minimize the risk of punctures. But such a technique will not be able to gain great speed.

Tire pressure levels

Tracked "tinger"

A very versatile, but limited in speed, all-terrain vehicle on a caterpillar suspension. The absence of tires means that there is no need to be afraid of a sudden tube puncture, but the maximum speed of movement of such vehicles on land is only 45 km / h. On water, this all-terrain vehicle also does not accelerate much - only up to 4 km / h.

And more interesting: Rusak all-terrain vehicle: specifications, official website, price, reviews, where to buy

The cabin of the Tinger amphibious vehicle is a closed structure that can accommodate up to 5 people. Riding in such a vehicle is quite comfortable in all weather conditions.

Cabin features and capacity

The weight of the equipment and its maneuverability depends on the number of passengers. The most nimble are double all-terrain vehicles. Most of them do not even have a cab - they look like motorcycles. Another plus is their low fuel consumption. They are chosen by huntsmen and rescuers for fast movement over long distances.

To go out into the countryside with a large company, all-terrain vehicles with a cabin are needed, where 4-6 people can fit. Good models with a heated cabin and a closed body for long journeys in cold climates.

Best-selling all-terrain vehicle models from different manufacturers

It is much easier to make a choice in favor of one or another model of an all-terrain vehicle on low-pressure tires if you know which ones are the most popular and why. You can do this by reading the reviews of the owners and analyzing the main characteristics.

Max brand models

Three variants of all-terrain vehicles of this brand are popular:

- maneuverable "Max 2" for two people;

- roomy "Max 4" for six people;

- cargo Buffalo.

The first two models are classified as universal, since it is not difficult for them to move from land to the surface of the water and continue to move at a speed of 12 km / h. On dry ground, the technique is capable of gaining speed up to 75 km / h. Each of the six wheels has independent control, which allows you to overcome any obstacle.

Argo 8×8 OutFitter

Both versions of this model - on caterpillar and on wheels - are popular with extreme sports all over the world. In the wheel version, she has eight tires. This is a universal model capable of moving over rocks, swamps, snow-covered ground and ice, as well as through water.

Argo 8x8 OutFitter

Amphibian Tinger

Its advantage is almost absolute cross-country ability, and its disadvantage is low speed (largely due to the tracked device for movement). Speed maximum on land - 45 km / h, on water - 4 km / h.

But he has a roomy closed cabin, where five travelers are freely accommodated. They are completely protected from the vicissitudes of the weather. This is a great option for those who value comfort more than speed of movement.

Amphibian Tinger - dimensions

All-terrain vehicle "Transmash"

It is more often used as a cargo one, because it has tracks and a large closed-type body. But it can also transport people - up to ten people at a time. Despite the large mass, it easily moves through the snow, mud, windbreak.

Maneuverable "TARUS 2X2"

This model will be chosen by a person who likes to hunt, fish or just go out into nature alone. A light all-terrain vehicle on two wheels will pass through any obstacles and impassability. If desired, it is easy to disassemble and pack in the trunk of a roomy car for long-distance moving.

Video test homemade all-terrain vehicle

The main bearing element of the additional frame is an arc bent from a pipe Ø 42 mm. Its rigidity is also ensured by pipes that form a strong triangle, an additional spacer from a 0 42 mm pipe and four struts of the upper frame belt. Such a complex shape was required in order to correctly distribute the mass of the all-terrain vehicle on the wheels, to place a third passenger on it.

Fig.1. The appearance of an all-terrain vehicle on a pneumatic hoist made by hand.

Seats on an all-terrain vehicle of a motorcycle type (regular), without any alterations; the way they are attached is the same as on a motorcycle. They are spaced apart from each other, taking into account the average height of a person and the convenience of landing. The factory seat handles have been replaced with rigid uprights with 240mm bars that are very comfortable to hold on to. A tool box is installed between the last and penultimate seats under the upper belt of the frame; a medical kit is attached to it. Behind the front seat, instead of batteries, a 2.5-liter canister with engine oil is installed on a bracket. The rear part of the frame of the upper belt ends with an arc, under which a reserve fuel tank with a capacity of 7 liters is installed.

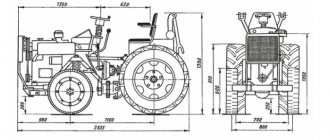

Rice. 2. An all-terrain vehicle on a pneumatic hoist based on a motorcycle "Ural":

1 - airway frame, 2 - engine, 3 - oil canister, 4 - direction indicators, 5 - first aid kit, 6 - driver and passenger steps, 7 - additional fuel tank, 8 - brake light, 9 - wheel, 10 - arches safety, 11 passenger support handles.

The rear axle is very simple in design and affordable for manufacturing. The main requirement for its assembly is the accuracy and alignment of the axle shafts. Therefore, the yoke arc is welded to them after assembly. Half shafts - from the GAZ-69 car (long), or, somewhat better, from the Volga GAZ-21: when using the latter, the wheel disk can be immediately put on the studs (and the GAZ-69 half shaft is connected to the disk through an additional flange). The axle shafts are machined with a diameter of 80 mm, seated in closed bearings (No. 180206) and assembled into a cardan tube (from GAZ-6Z) with an outer diameter of 76 mm. Each semi-axle rotates in four bearings (two on each side), which provides the unit with long and reliable operation.

Rice. 3. Refinement of the frame of the motorcycle "Ural".

The right and left halves of the bridge are joined in slotted bushings installed inside the driven sprocket. The splines on the axle shafts are cut and splined bushings for the driven sprocket are machined along them. The latter has 56 teeth, its diameter is 336 mm, and the drive, mounted on the final drive gearbox, is 28 teeth (both sprockets, together with chains, are from a decommissioned combine). The gear ratio of the rear axle in relation to the final drive is 2:1.

Rice. 4. Rear axle homemade air travel:

1 - axle shaft (from the GAZ-69 car, machined to a diameter of 30 mm), 2 - stocking (steel pipe with a diameter of 76 x 2 mm), 3 - bearings (No. 180206), 4 - driven sprocket (Z = 56), 5 - sprocket bushing, 6 - yoke post (pipe 34 mm in diameter), 7 - yoke arc (pipe 34 mm in diameter), 8 - axle shaft (from the GAZ-69 car, machined to a diameter of 30 mm), 9 - bearings (No. 180206), 10 - flange, 11 - spacer sleeve, 12, 14 - electric rivets, 13 - splined bushings, 15 - bushings for bearings.

The rear axle is fixed to the frame with clamps using M10 threaded bolts. After the alignment of the longitudinal axes of the driving and driven sprockets, limiting ears are welded on the rear axle to prevent the axle from moving along the segments under heavy loads.

Rice. 5. Front fork of a self-made all-terrain vehicle on a pneumatic hoist:

1 - fork feathers, 2 - reinforcing scarf (external), 3 - reinforcing scarf (internal), 4 - upper arc of the fork (pipe with a diameter of 42 x 3 mm), 5 - telescopic shock absorbers (from the Ural motorcycle, shortened from above by 50 mm), 6 - caliper stopper clamp, 7 - stopper, 8 - wheel disk (from the UAZ-469 car, facilitated by drilling holes), 9 - wheel hub (from the Ural motorcycle), 10 - spot welding seam (pitch - 20 mm), 11 - axle of the front wheel (the axle of the rear wheel of the Ural motorcycle is used, 12 - electric rivets.

The pneumatic chambers came from tractor trailers of type 1 PTS-9 or 3 PTS-12 (they are used with Kirovets or T-150 tractors). We limited the wheel diameter to a longitudinal belt 150 mm wide, and its thickness - ten transverse belts 50 mm wide and 1300 mm long. Automobile wheel rims - from UAZ-469. True, I had to lighten them as much as possible - to drill or mill a number of holes. The pressure in the wheels is not higher than 0.3 kg / cm2, and even less when driving on soft snow. When installing a wheel on a disc, a tire is put on top of the chamber, made from the same chamber, cut along its smaller circumference.

Initially, we made an unsprung front fork, but due to its rigid wheel travel when driving a snowmobile, it had to be abandoned. New version - with telescopic shock absorbers. We used the feathers from the Ural motorcycle, shortened them by 50 mm, and then pressed them into the tubes of the fork base. Feathers are fixed with welding points - electric rivets. In the lower part of the feathers, the clamps are cut off and others are welded instead, under the axis 0 36 mm. The axle of the front wheel of the all-terrain vehicle is made of feathers of the front fork of a motorcycle, connected by a long axis from the rear wheel of the motorcycle. One end is inserted into the pipe and fixed with electric rivets, and the other end is wrapped in a threaded sleeve. The bushing is pressed in and also secured with electric rivets.

The wheel hub, along with the brake mechanism, was not altered. The wheel disc is attached to the hub by welding: on the one hand - to the flange 0 105 mm, and on the other - to the brake drum. The brake mechanism is kept from turning when braking by a stopper. The latter is put on the axis and fits tightly into the groove of the caliper; the stopper itself is attached to the feathers of the fork with a clamp and two MB screws. There are also two brackets on the fork for mounting two additional headlights.

The main gear reducer together with the wheel hub is left unchanged. A specially machined washer is welded to the wheel hub (to its small flange), and a drive sprocket (Z = 28) is seated and screwed on it (if you use wheels of a different diameter for an all-terrain vehicle, you will have to choose another drive sprocket). The chain has a tensioner - it is a small sprocket (Z = 10) installed in a channel with a longitudinal hole, which is welded to the transverse pipe of the main arc.

Our all-terrain vehicle has a front windshield, it protects well from the wind. The steering wheel for convenience is extended to 1 meter; on top of it is a transverse traverse, on which the frontal shield rests. The all-terrain vehicle is equipped with headlights, direction indicators, brake lights and parking lights.

The brake system with a drive on all three wheels allows you to quickly stop, if necessary, even on the most slippery roads.

For reliable operation of the engine and its start, a magneto is installed on it.

Electrical equipment - 12-volt, with a DC generator and a relay-regulator RR-24G-2.

There is no battery on our all-terrain vehicle, the generator provides engine operation already at 700 rpm.

Reliable brakes, availability of lighting devices, ergonomics in accordance with the requirements of GOST for motorcycles - all this makes it possible to use the car in winter and on the roads of our city.

In the design of the all-terrain vehicle-pneumatic vehicle "Patrol" we used the most proven and reliable components from serial motorcycles and cars. The operation of the all-terrain vehicle showed its high reliability. On slippery ice or the road, it proved to be very stable due to the blocking of the rear axle shafts. The all-terrain vehicle easily overcomes steep climbs; engine power with a large margin is enough to transport three people on dense snow, tow skiers.

The mass of the all-terrain vehicle is about 400 kg, so it is difficult to use it on loose snow with a depth of more than 50 cm. This circumstance makes it necessary to put skis instead of the front wheel. The speed of the all-terrain vehicle on dense snow is up to 100 km / h, fuel consumption: 8-9 liters per 100 km.

There were doubts about handling: after all, we did not use the differential. But the all-terrain vehicle turned out to be extremely obedient and easy to drive in the snow: when my son was 8 years old, he confidently coped with the car.

And one more long-forgotten “novelty” in our all-terrain vehicle is a device for rocking the wheels. Instead of a candle, we wrap a fitting in one of the cylinders, inside of which there is a check valve, adjusted to a pressure of 0.5 atm. At the end of the fitting is a hose. We start the engine on one cylinder and inflate any wheel.

Among amateur designers of all-terrain vehicles, low-pressure wheels of their own production are very popular. The beginning of the history of the use of this type of propulsion by enthusiasts of homemade all-terrain vehicles can be considered the mid-sixties of the last century.

It was then that the first timid attempts were made to master the manufacture of wheeled vehicles capable of moving with equal success through wetlands and virgin snow. All of these machines were equipped with low-pressure pneumatics, and became the progenitors of today's homemade products.

Selection rules

For someone who wants to buy a snow and swamp-going vehicle with low-pressure tires, it is quite difficult to make a choice. Before this, it is necessary to analyze the possibilities of using equipment and the characteristics of the soil in the area.

Tracked all-terrain vehicle

Wheeled all-terrain vehicles are more maneuverable, lighter, and develop good speed. But sometimes a variant with caterpillars is required. They have better grip on clay surfaces, and the possibility of tire damage when driving through a forest littered with dry branches is excluded.

Consider how many people the model should accommodate. For solo travelers, it makes no sense to buy heavy transport - it is uneconomical.

Many owners of snow and swamp vehicles on ultra-low pressure wheels believe that domestic equipment is better in their native spaces. It has already been adjusted to local realities, is not afraid of temperature changes and is easily repaired in field conditions.

All-terrain vehicles are necessary for connoisseurs of natural beauty, which cannot be reached by an ordinary SUV. If you choose the right model, a trip to the most remote corners will turn into a pleasant and exciting journey.

Related video: Unex snow and swamp vehicle

Related publications

Making a receiver for a compressor with your own hands

Structural characteristics of different models of John Deere forwarders

Specifications and device ZIL 157